Boeing 747-200

China Airlines Flight CI611, B-18255

Makung, Penghu Island

May 25, 2002

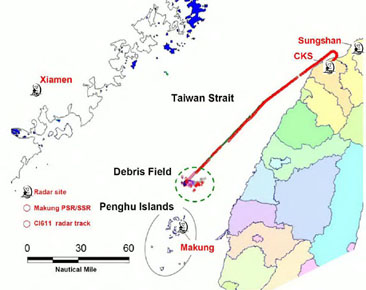

On May 25, 2002, China Airlines Flight CI611, a Boeing Model 747-200 series airplane, experienced an in-flight breakup over the Taiwan Strait. The most probable cause of the accident was the structural failure of a 22-year-old tailstrike repair located on the aft lower lobe of the fuselage. The skin scratches associated with the tailstrike event had not been removed prior to installation of the permanent repair doubler. Over time and airplane cycling, multi-site cracking progressed from the scratches, ultimately leading to a catastrophic failure of the airframe.

History of Flight

China Airlines (CAL) Flight CI611, a Boeing Model 747-200 series airplane, was a regularly scheduled flight from Chiang Kai Shek International Airport (CKS), Taoyuan, Taiwan, Republic of China, to Chek Lap Kok International Airport, Hong Kong. Flight CI611 was operating in accordance with the Republic of China Civil Aviation Administration (CAA) regulations.

There were 206 passengers, two pilots, one flight engineer, and 16 cabin crewmembers. The takeoff and climb were normal. Just prior to reaching an altitude of 35,000 feet, Flight CI611 experienced an in-flight breakup over the Taiwan Strait. There was no distress signal or communication sent out prior to the crash. Based on cockpit voice recorder (CVR) and flight data recorder (FDR), radar data, the wreckage distribution, and the wreckage examination, the in-flight breakup of Flight CI611 was most probably due to an airframe structural failure centered near the aft lower lobe of the fuselage.

Wreckage Recovery

Floating wreckage was sighted in an area 23 nautical miles northeast of Makung, Penghu. An immediate search and rescue operation was initiated. Searchers recovered 162 bodies and fifteen percent of the wreckage. No signs of burns, explosives, or gunshots were found.

Airplane History

Photo copyright Bastiaan Smeets - Used with permission

China Airlines Flight CI611, (a Boeing Model 747-200 series airplane, B-18255) was delivered to China Airlines on August 2, 1979. At the time of the in-flight breakup, this airplane had accrued 64,810 total flight hours and 21,398 total flight cycles.

On February 7, 1980, the airplane experienced tailstrike damage during landing on the runway at Kai Tec Airport, Hong Kong. After touchdown, the airplane was rotated to too high an attitude, and the aft portion of the fuselage struck the ground, scraping and damaging a portion of the lower aft body skin.

After the tailstrike, preliminary inspection revealed fuselage skin abrasion damage on the aft fuselage portion of the bottom skin between body station (BS) 2080 and BS 2160, and between BS 2578 and BS 2658. The aft drain mast was missing and the left outflow valve door inboard corner was partially open.

According to an airline report, the aircraft was ferried back to a maintenance facility in an unpressurized condition. A temporary repair was completed overnight in order to release the airplane back into revenue service. The temporary repair was to be replaced within four months with a permanent repair.

(See Temporary Repair / Copy of Temporary Repair Instructions)

Instructions for the temporary repair are as follows:

- Perform a close visual inspection of the internal structure for any damage that may be present in and around the abraded area.

- Install two reinforcing doublers made of 0.063 inch 7075-T6 aluminum alloy sheets.

- Replace the temporary repair with a permanent repair from the structural repair manual within four months.

Note: the temporary repair did not require the abrasion damage to be removed prior to installing the repair doubler over the fuselage skin.

Permanent Repair

The airplane logbook indicated that the permanent repair had been completed on May 25, 1980. A detailed description of the configuration of the permanent repair is unavailable since, at the time of this repair, CAL classified this repair as minor and therefore minimal documentation and approvals were required.

Structural evidence from crash site

From the sections of fuselage that were retrieved from the wreckage site, examination of the skin area (under the doubler) from the region suspected to have initiated the structural failure revealed many longitudinal scratches (fore and aft) existing on the faying surface of the skin.

showing repair doublers similiar to the Section 46

repair doublers which provoked the structural failure

An attempt to blend out the damage was apparent from evidence of sanding marks in the rework area. However, the permanent repair of the tailstrike was determined to have not been accomplished in accordance with the Boeing 747 Structural Repair Manual (SRM). The permanent repair would have required removal (trim out) of the damaged area. Evaluation of the remaining skin from the wreckage showed that the longitudinal scratches in the skin had not been trimmed out (i.e., damage not removed) and the repair doubler that had been installed did not extend sufficiently beyond the damage area.

The requirement for a permanent structural repair to extend beyond the damaged area into undamaged material, usually two to three fastener rows, provides for an alternate load path that evenly distributes the load into and out of the repair doubler. The even distribution of load is a key feature of a repair with good fatigue properties.

Since this repair did not fully encompass the damage area, there was a small region just outside the outer fastener row that had long scratches running fore and aft, perpendicular to the hoop direction. The skin scratches were a site of stress concentration, increasing the fatigue stresses locally at the base of the scratch. Increased fatigue stress leads to a shorter fatigue life and early crack propagation.

The skin scratches were covered from view by the edge of the repair doubler. Evidence of fatigue damage had been found at these skin scratches in the lower aft fuselage, centered about BS 2100 between stringers S-48L and S-49L. Multiple site damage (MSD), including a 15.1-inch-through thickness main fatigue crack and some small fatigue cracks, was confirmed. The 15.1-inch crack and most of the MSD cracks started from the scratching damage associated with the 1980 tailstrike incident.

(See Location of Repair Doubler Diagram)

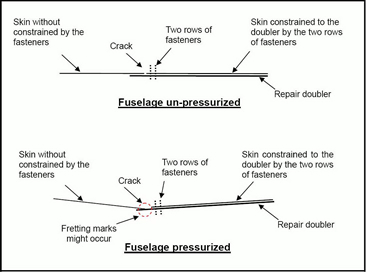

The local MSD cracking began to locally coalesce and link up into larger cracks. Since the scratches existed just under the lip of the repair doubler, as local MSD cracking began to link up into larger cracks, the edge of the large crack impinged on the doubler and caused rubbing or fretting against the inside surface of the doubler.

As the cracks continued to grow in length, the external doubler prevented the underlying skin from bulging outward in place such that any obvious damage (e.g. visible cracks during a walk around or inability to pressurize airplane) was not apparent.

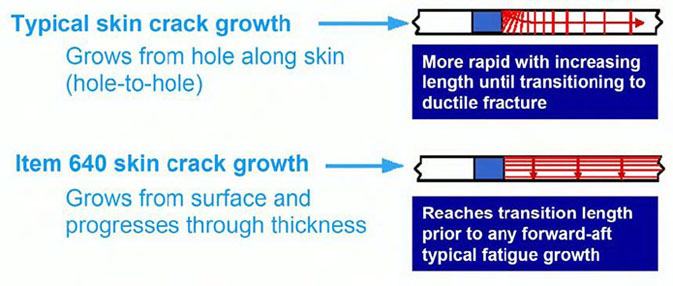

(See Evidence retrieved from wreckage showed different types of crack growth)

Structural damage tolerance analysis has indicated that, during application of normal operational loads, the structural integrity of the fuselage would be compromised with a continuous crack of 58 inches or longer. The evidence suggests that a very large continuous crack of at least 71 inches was present before the in-flight breakup of the aircraft.

(See Section of fuselage skin retrieved from wreckage showing failed skin)

Inspection programs already in place

Corrosion Prevention and Control Program

As part of the "Aging Airplane" programs put in place after the 1988 Aloha Airlines accident, this airplane received inspections in the proximity of the "tailstrike repair" area for corrosion through the Corrosion Prevention and Control Program (CPCP). The CPCP provides for directed visual inspection in areas that are susceptible to corrosion. These inspections were incorporated into CAL's airplane maintenance program.

Although this area had received internal inspections several times during the service life of this airplane, the last time approximately four years before the in-flight breakup, the cracking under the repair doubler was not detected. It is unclear whether the crack would have been noticeable by visual inspection methods since the crack would have grown inwards from the outboard side of the skin (scratch). The typical crack grows through the thickness of the material and then along its length, yielding more inspection opportunities to detect the growing crack before it reaches a critical size.

Repair Assessment Program

The operator had completed Stage 1 evaluation of the existing repairs common to the fuselage pressure vessel of the accident aircraft. Review of these maintenance records revealed traces of staining on the aft lower lobe fuselage around BS 2100. Staining of the exterior of the fuselage skin has long been used as a quick evaluation tool for breaches in the pressure vessel (i.e., structural cracks, pressure seal leaks, etc). Over time dirt, cigarette smoke and other particulate matter accumulate on the interior side of the fuselage skin. At a small breach in the pressure vessel, an air leak into the airstream forms due to the differences in pressure between the inside and outside of the fuselage. Cabin air, mixed with the particulate matter, flow through the breach, enter the airstream and coat the side of the fuselage leaving a stain. These dark traces (stains) were an indication of possible hidden structural damage beneath the doubler.

1) Based on the CVR and FDR recordings, radar data, and the wreckage examinations, the in-flight breakup of Flight CI611 was highly likely due to the structural failure in the aft lower lobe section of the fuselage.

2) On February 7, 1980, the accident aircraft suffered a tailstrike occurrence in Hong Kong. The aircraft was ferried back unpressurized to Taiwan on the same day, and a temporary repair was conducted the following day. A permanent repair was conducted from May 23 through 26, 1980.

3) The permanent repair of the tailstrike was not accomplished in accordance with the Boeing 747 SRM. The damaged skin in section 46 was not removed (trimmed), and the repair doubler did not extend sufficiently beyond the entire damaged area to restore the structural strength.

4) Evidence of fatigue damage was found in the lower aft fuselage centered about STA 2100, between stringers S-48L and S-49L, under the repair doubler near its edge and outside the outer row of securing rivets. In addition to the large fatigue crack, there was evidence of MSD that had initiated from the scratching damage associated with the 1980 tailstrike incident.

5) Residual strength analysis indicated that the main fatigue crack in combination with the MSD were of sufficient magnitude and distribution to facilitate the local linking of the fatigue cracks as to produce a continuous crack within a two-bay region (40 inches). Analysis further indicated that, during the application of normal operational loads, the residual strength of the fuselage would be compromised with a continuous crack of 58 inches or longer in length. Although the Republic of China's Aviation Safety Council (ASC) could not determine the length of cracking prior to the accident flight, the ASC believes that the extent of hoop-wise fretting marks found on the doubler and the regularly spaced marks and deformed cladding found on the fracture surface suggest that a continuous crack of at least 71 inches in length, a crack length considered long enough to cause structural separation of the fuselage, was present before the in-flight breakup of the aircraft.

6) Maintenance inspection of this aircraft did not detect the ineffective 1980 structural repair and the fatigue cracks that were developing under the repair doubler. However, the time that the fatigue cracks propagated through the skin thickness could not be determined.

Vol 1 of the ASC Accident Reports

Vol 2 of the ASC Accident Reports

National Transportation Safety Board (NTSB) Safety Recommendations A-03-07 through A-03-10:

A-03-007: Establish appropriate criteria (taking into account the size of repair and other relevant considerations) to identify those pressure vessel repairs to transport-category airplanes that could be hiding damage that, if not addressed, may lead to multiple-site fatigue damage and fatigue cracking and could result in structural failure of the airplane.

A-03-008: Issue an airworthiness directive (AD) requiring all operators of transport-category airplanes with pressure vessel repairs (identified as a result of applying the criteria discussed in Safety Recommendation A-03-007) to perform similar tasks as to those required by AD 2003-03-19, amendment 39-13044 (68 FR 5805, February 5, 2004), applicable to all Boeing Model 747 series airplanes.

A-03-009: Inform maintenance personnel about the circumstances of this accident. Emphasize that improper repairs to the pressure vessel may be hiding damage that allows the development of multiple-site fatigue damage and fatigue fracturing that could lead to structural failure.

A-03-010: Require the manufacturers of pressurized transport-category airplanes to include in their structural repair manuals, training programs, and other maintenance guidance, warnings about the possibility of structural failure resulting from hidden damage.

This airplane was approved to operate under Title 14 of the Code of Federal Regulations Part 129 (14 CFR part 129), which has very limited authority over non-US registered airplanes. The FAA had no jurisdiction over the daily operation or maintenance of this airplane. This airplane was operated and maintained in accordance with Republic of China Civil Aviation Administration regulations. According to China Airlines engineering orders for this airplane, the temporary repair should have been followed up with a permanent repair in accordance with the Boeing Structural Repair Manual. Accident investigators found evidence that the repair was not performed per China Airlines instructions.

Further, China Airlines also applied the provisions of 14 CFR 121.370 which specifies an assessment program for certain airplane models relative to the integrity of the pressurized fuselage, and associated life limits. At the time of the accident, China Airlines had completed stage 1 of the assessment program. The specific regulations is available at the following link:

14 CFR 121.370 - Operating Requirements: Domestic, Flag, and Supplemental Operations

In Addition, Advisory Circular AC 120-73, Damage Tolerance Assessment of Repairs to Pressurized Fuselages, provided guidance on incorporating "repair assessment guidelines" in air carrier maintenance or inspection programs subject to Title 14, Code of Federal Regulations (14 CFR) part 121.

The long scratches that remained from the original 1980 tailstrike were never removed as required by the Boeing 747 SRM repair. These surface defects were covered up but not structurally reinforced with a large doubler. The large doubler did not allow the skin to bulge outward as skin failure progressed, leading to a more severe failure scenario since the propagating skin crack remained hidden from view. Continued operation with scratches in place lead to MSD along the length of the scratch. With additional flight cycling, the numerous small MSD cracks linked up to form large cracks. Ultimately, the loss of structural capability of the fuselage skin led to structural overload of the reinforcing frames, and an in-flight breakup of the structure occurred.

The scenario described above took 22 years to complete. It started with an improper repair which covered up the growing crack and made damage detectability through standard maintenance inspections improbable.

Although several maintenance programs did inspect the area over the course of the airplane's service life, they were not sufficient to detect the growing crack. The maintenance programs in place are designed to find age-/cycle-related structural deterioration as the fleet experiences natural aging from a pristine as-delivered configuration. The maintenance programs tend to be exploratory in nature and usually allow operator adjustments based on the overall performance of their fleet. They are not designed to detect rapidly deteriorating conditions due to a singular event occurring on an individual airplane. Continued operational safety on individual airplanes is ensured by adhering to standard repair and maintenance practices.

1) The original repair was identified as minor. Minor repairs by their nature are not considered to have an effect on safety. This proved to be incorrect. In accordance with Appendix A "Major Alterations, Major Repairs, and Preventive Maintenance," of Part 43 of the FARs, repairs performed in order to reestablish the structural integrity of a primary structural member would be identified as major repairs.

2) Maintenance programs have severe limitations related to detecting certain types of damage. Hidden damage requires specially designed directed inspections. Maintenance inspections generally cannot be relied upon to detect deteriorating conditions stemming from improper repair or maintenance. The assumptions used to design the inspection programs are based on the airframe loading and environmental conditions.

Japan Airlines (JAL) Flight 123 had a repair installed on the aft pressure bulkhead. This installed repair deviated from the FAA approved repair in a manner that reduced the fatigue life of the structure at critical fastener location, leading to early structural fatigue failure and subsequent explosive decompression of the pressure bulkhead. The structural decompression led to catastrophic loss of airplane control. The common theme between CAL Flight CI611 and JAL Flight 123 is the lack of adherence to repair installation instructions leading to catastrophic failure of the airplane. JAL Flight 123 was a Boeing Model 747SR series airplane that crashed in the mountains near Gunma Prefecture, Japan, on August 12, 1985.

See accident module

There were no general policies or regulations released as a consequence of this accident. However, this accident altered the sensitivity of the industry in the way it addresses long, shallow types of damage found in pressurized fuselage structure.

Subsequent to this accident was the discovery of scribe line damage found on fuselage skin. This type of damage also stemmed from improper maintenance, specifically use of a utility knife against the fuselage skin to remove external sealant prior to the repainting of an airframe. This issue was treated as a serious safety concern primarily due to the Flight CI611 accident. The CI611 accident increased overall industry sensitivity to the potential of surface defects to cause structural failures.

AD 2003-03-19 was released as an immediate adopted rule. This AD applied to all Boeing model 747 series airplanes certificated in any category. released as an immediately adopted rule. This AD applied to all Boeing Model 747 series airplanes. This AD mandated a general visual inspection for evidence of a tailstrike repair having been accomplished on the lower aft fuselage prior to any airplane reaching 15,000 total flight cycles or within 90 days, whichever is later. If the airplane had a repair doubler in the area between BS 1961 and BS 2360, this AD required that:

1) For doublers having fewer than 10,000 total flight cycles, the doubler should be removed, and a skin inspection/assessment be performed (this inspection/assessment is looking for skin scratches or other damage that could lead to early skin cracking) prior to the doubler accumulating 10,000 total flight cycles, or

2) Depending on the size and position of the doubler, either internal mid-frequency

eddy current (MFEC) or an external detailed inspection of the fuselage skin for damage be done.

Larger doublers are inspected more frequently. If scratches are found during any of these inspections, then removal and further inspection of the repair doubler is required within 1,000 flight cycles, or 18 months, whichever is first.

Airplane Life Cycle:

- Maintenance / Repair / Alteration

Accident Threat Categories:

- Structural Failure

Groupings:

- N/A

Accident Common Themes:

- Organizational Lapses

- Pre-existing Failures

- Unintended Effects

Organizational Lapses

The installed permanent repair was not performed in accordance with approved instructions. While the repair was failing, the failure remained undetectable by general inspections until the structural capability fell below what was required to maintain airworthiness. Multiple inspection opportunities should have detected the progressive failure (for example, external streaking visible around the repair doubler), however, maintenance and inspection personnel were not trained in, or did not recognize, the significance of the available cues, and associate those cues with the early stages of structural failure.

Preexisting Failures

The incorrect repair was performed years before the actual skin failure and in-flight breakup of the airplane. As a result of the repair, cracking in the skin occurred which was not detectable due to the nature of the repair (the skin doubler hid any cracks that formed), allowing cracking to progress over many years until the ultimate failure occurred.

Unintended Effects

The skin doubler and other cosmetic treatment of the aft body skin were intended to repair the damage resulting from the landing tailstrike. The improper application of the repair, rather than enhancing the structural integrity of the skin, actually contributed to the ultimate failure.

JAL Flight 123, a Boeing Model 747SR series airplane, had a repair to the aft pressure bulkhead which was installed improperly. The structural reinforcement was cut to aid in installation; however, the cut eliminated the reinforcing benefit of the strap and caused early fatigue failure of the pressure web. The deficient area of the repair was ultimately covered up from the forward side; therefore, visual inspectability was impaired, and visual inspections did not identify the deteriorating structure. The cracking began as local MSD, and then coalesced in a rapid manner, and final cracking proceeded rapidly to reduce the residual strength capability below the structural requirements. An explosive decompression took place when the aft pressure bulkhead repair failed. This rapid pressure loss caused collateral damage to the control system, yielding loss of control of the airplane. The airplane crashed in the mountains near Gunma Prefecture, Japan, on August 12, 1985. There were 520 fatalities and four survivors.

See accident module

Aloha Airlines, a Boeing Model 737-200 series airplane, experienced MSD (numerous small cracks) at the lower row of the fuselage lap joint, leading to crack link-up and subsequent loss of a large portion of the upper lobe of the fuselage. The airplane landed safely on April 28, 1988, with only one fatality.

See accident module

Technical Related Lessons:

Many areas of the airplane’s skin are highly loaded structural surfaces, intended to transmit loads into other structural members (stringers, frames and ribs). Skin surface scratches, scrapes, scribe marks, and other forms of damage can cause stress concentrations to occur, and result in the formation of fatigue cracks when subjected to subsequent structural loading conditions. (Threat Category: Structural Failure)

- In this accident, it was determined that repairs following the tail strike did not completely remove scratches and scrapes in the lower fuselage skin. The area of the fuselage skin involved in this damage is structurally loaded due to cyclic pressure forces each time the airplane is pressurized during flight. The stress concentration caused by the scratches resulted in cracks forming, due to fatigue of the skin structure. After many years of pressure cycling, and additional fatigue, the resulting skin crack became quite large. Since the original repair also installed a doubler panel over the damage area, the large crack was not able to be discovered during subsequent structural inspections. The surrounding fuselage structure beneath the skin became overloaded and eventually failed, resulting in catastrophic in-flight breakup of the Boeing Model 747.

Common Theme Related Lessons:

Safety programs such as repairs, maintenance, modifications, and other in-service activities must either be accomplished consistent with the original airplane’s integrity and safety features, or the effects of these programs must be accounted for during all subsequent airplane operation and maintenance activities. (Common Theme: Organizational Lapses)

- The accident investigation concluded that instructions for the permanent repair (following the tail strike) were correct, however, they were improperly implemented. The scrapes and scratches from the tail strike incident were not completely removed during the repair process, and a doubler panel was installed which covered the scratches but did not extend beyond the damaged area. The remaining scratches allowed the formation of a large fatigue crack to form, and due to the doubler covering the damaged area, the large crack was not able to be discovered during subsequent structural inspections.