Beechcraft T-34

Photo copyright Bill Shull Photography – used with permission

The Air Force introduced the T-34 aircraft into inventory in 1953 and the Navy and Marine Corp commissioned the T-34B beginning in 1955. During military operations, the T-34 was a high-use aircraft that typically experienced numerous flights, landings, and g-force flight conditions. After military service as a primary pilot training aircraft, many Beech T-34s were considered surplus by the government and transitioned to civilian use. While in civilian operation, several T-34 airframes experienced inflight wing separations as a result of fatigue cracking, resulting in several major aircraft accidents.

The following three accidents are representative of T-34 accidents associated with structural fatigue failure:

Private Pilot, N140SW

Rydal, Georgia

April 19, 1999

A Beech T-34, N140SW, crashed near Rydal, Georgia following an in-flight separation of the right wing. The National Transportation Safety Board (NTSB) determined the probable cause of the accident to be a "fracture of the wing spar in result of fatigue cracking that took place over an unidentified number of flights and flight hours with a wing spectrum that was not taken into account during the design of the airplane."

Private Pilot, N44KK

Montgomery, Texas

November 19, 2003

A Beech T-34, N44KK, crashed following a loss of control due to an inflight breakup of the right wing. The NTSB determined the probable causes to be the "non-compliance with applicable Airworthiness Directives which required wing spar inspections and the continued operation of the aircraft beyond the compliance time extension granted as per the approved alternate means of compliance (AMOC). Also causal was the operation of the aircraft outside its flight G-load limitations."

Private Pilot, N141SW

Houston, Texas

December 7, 2004

A Beech T-34, N141SW, crashed due to an in-flight separation of the left wing. The NTSB determined the probable cause to be "the in-flight separation of the left wing as a result of extensive fatigue cracking throughout the wing carry-through structure."

History of Flights

Photo copyright Joost de Wit – used with permission

Beech A45 (T-34) Airplane

The Beech T-34 is a two-place, single-engine, tandem-seat trainer produced by Beech Aircraft Corporation. The T-34 was initially used by the military for training but was then put to use for aerobatics, air combat simulation flights, and personal use. The overall dimensions of the airplane are a wingspan of 33 feet, length of 25.11 feet, and height of 9.7 feet. This airplane was flight tested in 1949. The Air Force received the first of 450 T-34As in 1953. Production of the T-34B began in 1955 for use by the United States Navy.

According to the NTSB safety recommendation, T-34 N140SW was most likely delivered to the Air Force between 1954 and 1955. In 2004, due to a series of crashes involving in-flight structural failure during simulated combat flights, the FAA grounded the entire U.S. civilian fleet of T-34s. The planes are currently flying with reinforcement or replacement of the spars.

April 19, 1999 Accident

Photo copyright Chris Meisner – used with permission

Rydal, Georgia

On April 19, 1999 a Beech T-34, N140SW, departed from Fulton County Airport in Atlanta, Georgia at 1200 eastern daylight time. The agenda for the day's flight included simulated air combat engagements along with setting up a "beyond visual range engagement" with another Beech T-34 aircraft (N141SW). Beyond visual range engagement is a form of aerial warfare where the intended targets are out of sight. Radar and guided missiles can be used with this type of engagement. Roughly 45 minutes into the mission, both airplanes set up for "beyond visual range engagement" at a prearranged altitude and direction. After the primary run toward each other, N140SW began a downward turn. As reported by the pilot of the second T-34, while the accident aircraft navigated in the descending left turn with a rapid reversal, the right wing detached from the airplane and the airplane went into a rapid spin before colliding into the ground. Both the passenger and the transport pilot/safety pilot were fatally injured.

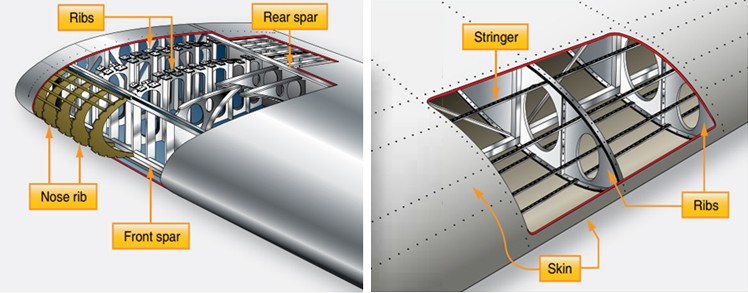

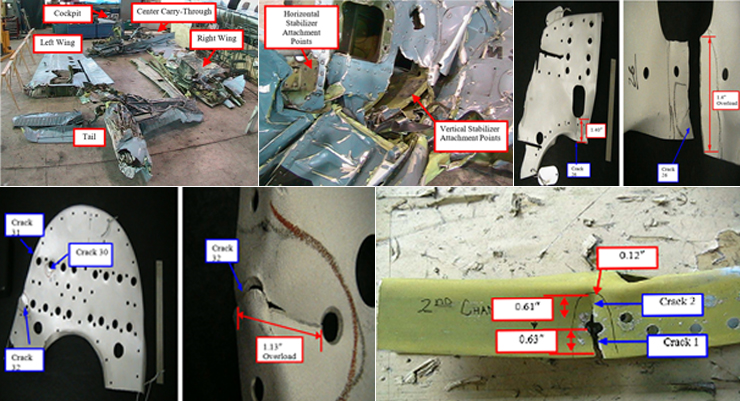

The NTSB final accident report states "the right wing forward spar separated at a point just outboard of the forward wing attach fittings. The rear spar separated in two locations. One area included the separation of the upper and lower spar cap assemblies at a point outboard of the right main landing gear aft trunnion fitting. The other area involved the area of the aft wing attach fittings. The rear spar upper cap assembly separated at a point just outboard of the aft upper wing attach fitting."

The wing spar is the main structural member of the wing that supports all distributed loads. The wing spar also supports concentrated weights such as the fuselage, landing gear, and engine. Wing attach fittings are located at the inboard end of the wing spars and provide a strong and secure method for attaching the wing to the fuselage.

The NTSB report stated maintenance records showed that the accident aircraft was routinely inspected under a wing spar X-ray program since 1996. During this timeframe, no significant findings were discovered under this inspection program initiated by the operator. According to the operator, "records of cumulative G-loading for each flight were not maintained.

The NTSB Safety Recommendation stated that the air combat simulation flights lasted for about 75 minutes, and the pilots were requested not to exceed 4 Gs in the positive direction. Earlier in the accident flight, according to the audio portion of a videotape made during the flight, the pilot informed the passenger that they had performed a 4.5 to 5-G turn. According to the NTSB "one of the other airplanes reportedly experienced a 12-G loading during one mission." The T-34 design G-load limits are +6.0 and -3.0. According to the NTSB safety recommendation, the accident aircraft was likely delivered to the Air Force between 1954 and 1955.

View Larger Photo1 Photo 2 Photo 3 Photo 4

November 19, 2003 Accident

Montgomery, Texas

Photo copyright Klaus Ecker – used with permission

On November 19, 2003, a Beech T-34, N44KK, collided with the ground due to an inflight separation of the right wing. The pilot-rated passenger was in training for a two-day advanced maneuvering program (AMP). Prior to the accident, the accident airplane and another Beech T-34 (N141SW) set up to engage in a simulated air combat demonstration and engaged at 7,500 feet and 140 knots. Both airplanes conducted a left climbing turn to begin maneuvering. Investigators determined that after two or three turns, the accident airplane broke up in flight and spun to the ground. The commercial pilot and pilot-rated passenger were fatally injured.

According to the NTSB final accident report, the aircraft was destroyed when it impacted terrain following a loss of control after an in-flight breakup of the right wing. The forward spar was fractured at Flight Station (FS) 34 and the rear spar fractured at FS 66.

A former customer of Texas Ace Air, who operated the aircraft, flew the accident aircraft in May 2001 and reported in a written statement that during the flights, he was "sitting in the front seat and didn't notice any type of G-meter installed." After the completion of the flight, the former customer asked the instructor pilot how many Gs were pulled and recalled the answer was about positive 6 Gs.

A pilot who flew the accident aircraft on May 2, 2001 reported in a written statement that he remembered the instructor telling him that "they had pulled something over six Gs" during the flight. The T-34 design G-load limits are +6.0 and -3.0.

December 7, 2004 Accident

Houston, Texas

Photo copyright Klaus Ecker – used with permission

On December 7, 2004, a Beech T-34, N141SW, departed from David Wayne Hooks Municipal Airport (DWH), near Houston, Texas at around 9:45am CST. After reaching 6,000 feet, the pilot in command and pilot-rated passenger began performing advanced training maneuvers. As stated in accident report, these maneuvers included "steep turns, stalls, accelerated stalls, unusual attitudes, and recoveries from these to a wings level attitude using several techniques." At 10:20, the aircraft crashed because of the in-flight separation of the left wing. The pilot in command and the pilot-rated passenger were both fatally injured.

According to the NTSB accident report, the aircraft "was destroyed when it impacted terrain following an in-flight separation of the left wing and subsequent loss of control." Inspection of the left wing showed that "the forward carry-through structure was fractured around station (STA) 17 and the rear spar fractured about STA 28."

View Larger Photo 1 Photo 2 Photo 3 Photo 4 Photo 5

Photo copyright Chris Meisner – used with permission

The aircraft was in service from September 1958 through January 1965, when it was released to the Civil Air Patrol. Following an accident in 1959, the owner turned over the aircraft to salvage for reclamation and disposition. Subsequently sold numerous times, it was then deregistered in 1982 and listed as "totally destroyed or scrapped," after an additional accident. The aircraft was sold five more times and, in 1990, the data plate was used to build a new airplane with new surplus and/or used, serviceable parts. The airplane was sold twice more and was owned by PRVNY PLUK, LLC and operated by Texas Air Aces, Inc. at the time of the accident.

Following military use, the T-34 was often sold for civilian use. In the 1950s, there was no requirement for fatigue life for the T-34 military trainers, and the magnitude and number of G-loads of an individual airplane was unknown. Thus, these aircraft were often not accompanied with valid G-loading information.

Once in civilian use, the T-34 G-load limits were frequently exceeded while pilots in command performed advanced maneuvers. Routinely flying at excessive G-loads resulted in a significant reduction in fatigue life. Additionally, since spare and salvaged parts are often combined on reconstructed airplanes, it was often not possible to determine the structural history of the airplane.

During inspections, assurances cannot be made that a component is not experiencing fatigue simply because no crack is found. Many of these aircraft have an unknown service history and inspectors have no way to determine the remaining fatigue life.

The following animation highlights the impact of fatigue life on an aircraft: Beech T-34 S-N Animation

Conclusion

After a history of military use and subsequent civil application, the combination of flight hours and cycles during both military and civil operations led to a series of Beech T-34 accidents involving inflight wing separations as a result of fatigue cracking. This fatigue cracking, brought about through extended use of the aircraft not expected during design, occurred in multiple critical areas. Inspection programs created through industry and regulatory directives did not completely identify all areas to be inspected. Compliance timelines associated with monitoring and oversight were not always followed. Further accidents revealed continued fatigue cracking until the aircraft was ultimately grounded.

Accident Board Findings for April 19, 1999 Accident

The NTSB determined the accident cause was a fracture of the wing spar as a result of fatigue cracking that occurred over an unknown number of flights and flight hours with a wing loading spectrum not anticipated during the design of the airplane.

The complete text of the accident report is available at the following link: Accident Report

Accident Board Findings for November 19, 2003 Accident

The NTSB determined the causes of the accident were non-compliance with applicable Airworthiness Directives which required wing spar inspections, and the continued operation of the aircraft beyond the compliance time extension granted as per the approved alternate means of compliance (AMOC). Also causal was the operation of the aircraft outside of its flight G-load limitations.

The complete text of the accident report is available at the following link: Accident Report

Accident Board Findings for December 7, 2004 Accident

The NTSB determined the cause of the accident was as the in-flight separation of the left wing as a result of extensive fatigue cracking throughout the wing carry-through structure.

The complete text of the accident report is available at the following link: Accident Report

Recommendations for April 19, 1999 Accident

Immediately restrict from further flight all Beech YT-34, T-34A, and T-34B airplanes that have been or are currently being used in air combat simulation flights until an inspection shows the airplanes to be airworthy. Immediately restrict all other Beech YT-34, T-34A, and T-34B airplanes from entering future air combat simulation flight service until an inspection shows the airplanes to be airworthy. (A-99-47, Urgent)"

"Require that operators of Beech YT-34, T-34A, and T-34B airplanes perform an inspection of the wings and other critical structures at an appropriate interval sufficient to detect cracking prior to failure (depending on the usage of the airplane), as soon as Raytheon Aircraft Company has developed an approved inspection procedure. (A-99-48)"

"Publicize the circumstances of the accident near Rydall, Georgia, and the potential for wing separation due to wing spar fatigue to all owners of Beech YT -34, T-34A, and T-34B airplanes. (A-99-49, Urgent)"

"Require the development of operational and inspection criteria for the critical flight control surfaces and structural elements, as necessary, for any airplane used in air combat simulation flights. (A-99-50)"

The complete text of the recommendations is available at the following link: Accident Recommendations

Recommendations for November 19, 2003 Accident

None issued.

Recommendations for December 7, 2004 Accident

None issued.

14 CFR 21.27: Issue of type certificate: surplus aircraft of the Armed Forces

14 CFR 23.572: Metallic wing, empennage, and associated structures

AC 21-54: Experimental Airworthiness Certification of Certain Former Military Aircraft

AC 23-13A: Fatigue, Fail-Safe, and Damage Tolerance Evaluation of Metallic Structure for Normal, Utility, Acrobatic, and Commuter Category Airplanes

AC 43-209A: Recommended Inspection Procedures for Former Military Aircraft

Order 8100.19: Destroyed and Scrapped Aircraft

Issuance of a standard airworthiness certificate requires that an aircraft must conform to its approved type design and be in a condition for safe operation. Additionally, prior to initial certification, eligible aircraft based on their Type Certificate Data Sheet (TCDS) must be modified in accordance with required regulations. TCDS provides a formal description of the aircraft, engine, or propeller that has received type certification by the FAA. The TCDS has the same regulatory status as the approved type design, operating limitations, and applicable regulations.

Below is the type certificate data sheet for the T-34 that requires military aircraft to be eligible for transfer to civilian use. The TCDS (specifically page 9) for this aircraft is as follows: 5A3 Rev 29

Operator/Pilot Culture

Taking a retired military trainer aircraft that reached the end of its service life, some of which had even been destroyed and rebuilt, has been a common practice. However, this presents a difficult challenge for the operator when converting the aircraft into civilian use. Adherence to inspections and parts replacement required by FAA directives must be monitored closely so as not to exceed the fatigue limit of the aircraft.

Civilian pilots often flew these aircraft at high G-loads. Due to a series of accident investigations, it was determined that staying within the G-load limits of the airplane was not a priority to operators nor pilots flying the airplanes. It is imperative that during operations, the aircraft's design G-limits not be exceeded. For example, according to an NTSB Safety Recommendation, one of the airplanes experienced a 12G loading during one mission when the structural limit was 6Gs. Most of the T-34 airplanes did not have G-meters installed.

- Between 1953 and 1958, there was no requirement for the establishment of a fatigue life for the T-34 military trainers

- The accumulated operational service history of the magnitude and number of G-loads of an individual airplane was unknown

- Given the intermingling of spare and salvaged parts installed on airplanes in military service, it is difficult to determine accurately the overall history of the airplane

- During civilian use, the design G-load limits of the aircraft were being exceeded

- Required inspections of structural components of the aircraft were often not conducted in areas where structural fatigue occurred; for example, the FAA revised AD 2001-13-18 because the AD did not address all critical areas in the wing spar assemblies

Pilots will adhere to the G-loading envelope.

- Investigations determined that the T-34 G-load limits were frequently exceeded while pilots in command performed advanced maneuvers.

Critical structural areas are properly identified and inspected, and failures will be detected.

- Investigators determined the aircraft has multiple critical areas in the wing spar which had not been previously inspected through the required inspection program

Military airplanes are introduced into civilian service with a valid G-loading history.

- During the 1950s there was no requirement for fatigue life for the T-34 military trainers, and the magnitude and number of G-loads of an individual airplane was unknown. Since spare and salvaged parts are combined on reconstructed airplanes, it is unfeasible to determine the overall structural history of the airplane.

Photo copyright Jetphotos - used with permission

Maracay, Venezuela, April 5, 1999

A Beech T-34 crashed after takeoff.

NTSB accident report: N/A

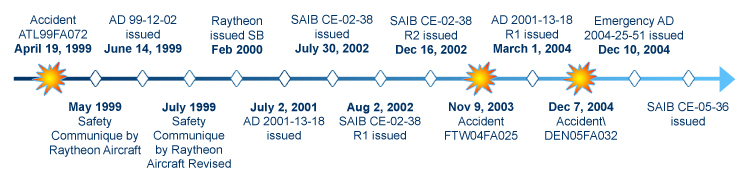

1) Safety Communique by Raytheon Aircraft: Issued May 1999 and revised July 1999 which addressed wing spar assembly and wing attachment fitting fatigue fractures. This communique grounded the YT-34, T-34A, T-34B and Bonanza 35 through G35 (with T-34 wings installed) airplanes until there was a final determination by the FAA.

2) Raytheon Aircraft Service Bulletin: Issued February 2000, this service bulletin provided inspection processes for the forward (main) and aft (rear) wing spars to discover fatigue cracks in specific areas. The specific areas were those where the cracks were discovered during the investigation of the April 1999 T-34 accident.

The service bulletin is separated into two parts, part one delivers instructions for modification and inspection of forward wing spar and aft wing spar structure for fatigue cracks and corrosion at suspected locations. Part two provides a recurring inspection process at 80-hour intervals. View Raytheon Aircraft Service Bulletin.

3) Special Airworthiness Information Bulletin (SAIB) CE-02-38: FAA issued this SAIB on December 16, 2002 to provide a means to extend the compliance time to AD-2001-13-18. Revision 1 (R1) clarifies the time allowed to accomplish required inspection and/or schedule modifications. Revision 2 (R2) added two alternatives to the repetitive inspection procedure. (alternatives to the Raytheon repetitive inspection procedure) View SAIB CE-02-38.

- SAIB CE-02-38R1, issued on August 7, 2002, and SAIB CE-02-38R2, issued on December 16, 2002, advised registered owners of a means to extend the compliance time of AD 2001-13-18. In other words, the SAIBs mentioned above approved alternative methods of compliance (AMOCs) to AD 2001-13-18.

- According to SAIB CE-02-38R2 "The FAA has been working with interested owners and modifiers to investigate structural modifications and alternative inspection procedures that would provide the same, or higher, level of safety as the inspections required" in AD 2001-13-18. As stated in SAIB CE-02-38R2 "Nogle and Black Aviation provided data to justify a front spar replacement per their STC with a new, stronger ‘common spar.'

- Aviadesign, Inc. provided data to justify an initial Raytheon inspection followed by installation of a steel strap (Saunders strap) to the wing

- Parks Industries Ltd., Inc. provided data to justify a front spar replacement per their STC with a new, stronger spar they manufacture

- The T-34 Spar Corporation provided data to justify a front spar modification per their instructions that cold works critical fastener holes and installs a strengthening doubler to the spar.

- The T-34 Association, Inc. and the T-34 Technical Committee submitted a fluorescent inspection procedure to inspect for cracks in the rear spar wing attachment fitting.

- All of the data provided and inspection procedures submitted from T-34 owners were proposed as an Alternative Method of Compliance (AMOC) to AD 2001-13-18 that the FAA approved.

4) Special Airworthiness Information Bulletin (SAIB) CE-05-36: March 7, 2005, the FAA issued this SAIB to make T-34 owners aware of an approved inspection program for airplanes that had not reached 3,800 hours of total time in service. In April 2005 the FAA issued several AMOCs that permitted most T-34s to fly with the limitations of not exceeding 152 knots, -0/+2.5 Gs, no aerobatic flying, avoid flying into moderate or severe turbulence, and undergo a surface eddy current inspection of the carry-through structure. View SAIB CE-05-36.

5) AC 91-82A: Fatigue Management Programs for In-Service Issues

1) June 14 1999, AD 99-12-02 Due to the 1999 accident in Rydall, Georgia, this AD was issued as a provisional action until the FAA approved inspection procedures. This AD required incorporating flight and operating limitations that restricted the airplanes to normal category operation only, which prohibited them from acrobatic and utility category operations. The flight load factor was limited to 0 to 2.5 Gs and the maximum airspeed was restricted to 175 miles per hour.

2) August 16 2001, AD 2001-13-18 Due to the 1999 accident in Rydall, Georgia, this AD superseded AD 99-12-02 and required procedures to repetitively inspect the wing spar assemblies for cracks with replacement of any wing spar assembly found cracked. It also included a reporting requirement of the results of the initial inspection, as required by Raytheon Aircraft Mandatory Service Bulletin SB 57-3329 issued February 2000. It maintained the flight and operating restrictions required by AD 99-12-02 until accomplishing the initial inspection.

3) March 15, 2004, AD 2001-13-18 R1 Due to the 2003 accident in Montgomery, Texas, the FAA had approved alternative methods of compliance (AMOCs) in AD 2001-13-18 but then determined that those AMOCs did not address all critical areas in the wing spar assemblies. This AD eliminated all the AMOCs to AD 2001-13-18 and required the instructions in Raytheon Aircraft Mandatory Service Bulletin SB 57-3329 issued in February 2000.

4) December 10, 2004, Emergency AD 2004-25-51 As a result of 2004 accident in Houston, Texas, this AD grounded the T-34 fleet and required an approved inspection before further flights. The AD did set operating limits similar to AD 99-12-02 to allow owners to get their aircraft to an appropriate location for the inspection.

- This accident resulted in the FAA issuing Emergency AD 2004-25-51 on December 10, 2004. As stated in AD 2004-25-51 the "FAA investigation revealed further visual evidence of fatigue (found in other locations) not previously addressed by AD 2001-13-18 R1."

- Maintenance records indicate that accident airplane, N141SW, was in compliance with AD 13-18-R1

- AD 2004-25-51 did not provide relief from AD 2001-13-18 R1

- In addition, AD 2004-25-51 effectively grounded the T-34 fleet and required owners to perform an inspection and/or modification program approved specifically for the AD by the FAA Wichita Aircraft Certification Office (ACO)

Airplane Life Cycle

- Operational

- Maintenance / Repair / Alteration

Accident Threat Categories

- Abrupt Maneuver

- Structural Failure

Groupings

- Business/Commercial

Accident Common Themes

- Organizational Lapses

- Pre-existing Failures

- Flawed Assumptions

Organizational Lapses

Surpassing the +6.0 and -3.0 G-load limits of the airplane could not be accurately determined during military use and was often disregarded by operators or pilots flying the airplanes in civil use.

Preexisting Failures

There are many challenges associated with transferring a military aircraft into civilian use. These include operational history, total number of flight hours, cycles, and monitoring of load limits. In the case of the T-34 aircraft, many aircraft were missing complete reports.

C-130 Hercules, June 17, 2002

According to the NTSB report, both wings of the C-130 Hercules were separated from the fuselage while making a fire-retardant drop. A twelve-inch-long fatigue crack on the lower surface of the right wing below the forward doubler was discovered by metallurgical examination. As stated in the accident report there were "two separate fatigue crack initiation sites at stringer attachment rivet holes (which join the external doubler and the internal stringers to the lower skin panel)." The cracks from both sites connected to create a single crack. Investigators determined that "the portion of the wing skin containing the fatigue crack was covered by a manufacturer-installed doubler, which would have hidden the crack from view and, therefore, prevented detection of the crack from a visual inspection of the exterior of the airplane."

Probable Cause

The NTSB determined the probable cause of this accident to be the in-flight separation of the right wing in result of fatigue cracking in the center wing lower skin and underlying structural members.

View LAX02GA201 Accident Report.

T-34, April 5, 1999

According to the safety communique released in May 1999 and revised in July 1999 by Raytheon Aircraft "another Beech T-34 crashed at Maracay, Venezuela, as a result of an in-flight wing separation following the performance of aerobatic maneuvers. An investigation was conducted by Venezuelan authorities for inspection by RAC metallurgists and we are not certain whether those surfaces would also reflect the presence of fatigue."

Technical Related Lessons

To ensure continued airworthiness, inspection program criteria must be sufficient to discover damage before there is risk of catastrophic failure, with consideration for how the aircraft is actually used. It is important that structural maintenance or other in-service programs be predicated on a thorough understanding of fatigue properties. (Threat Category: Structural Failure)

- As a result of T-34 accidents in 1999, 2003, and 2004 involving inflight wing separations, investigators determined the aircraft had multiple critical areas in the wing spar which had not been previously inspected through the required inspection program. Although directives and bulletins were implemented to preclude accidents, the previous structural inspection methods failed to identify later-known areas of the aircraft that failed.

- Inspection criteria must include identification of component location, test method used, and the inspection interval frequency. For non-destructive testing there are several approved test methods; however, the spar x-ray inspection methods were insufficient to discover damage before these accidents occurred.

- Fatigue evaluation; G-loading; cycle and landing tracking; and flight hour documentation are critical for continued airworthiness of former military aircraft. In these accidents, previous military flight history was unknown, cumulative G-loading was not documented, and fatigue evaluation programs were insufficient.

Common Theme Related Lessons

Operators should strictly adhere to G-load restrictions, so the aircraft is not exceeding design limitations. Excessive Gs can lead to wing loading that designers may not have anticipated, and which could result in wing spar fatigue cracking and, ultimately, structural failure. (Common Theme: Organizational Lapse)

- Investigators attribute these accidents to the fracture of the wing spar as a result of fatigue cracking occurring over an unknown number of flights and flight hours. Investigators concluded the operators likely exceeded G-load limits for the airplane.

Military aircraft are often subjected to extreme and unknown operating conditions and configuration status. Therefore, as part of transfer and acceptance, the airplane needs to be incorporated into a robust inspection program, confirming that the aircraft is airworthy before entering, and during, civilian service. (Common Theme: Pre-existing Failures)

- Certifying military aircraft into civilian use in order to issue an airworthiness certificate is a challenge due to the requirement for incorporating a maintenance and inspection program. As stated in the 1999 NTSB accident report "the accumulated operational service history - the magnitude and number of G-loads of an individual airplane is unknown." Due to the "intermingling of spare and salvaged parts installed on airplanes in military service, it is usually impossible to determine accurately the overall history of the airplane."

- Due to the manner and condition in which some military aircraft enter the civilian market, flight and maintenance records are, in some instances, incomplete. Because of this inconsistent traceability, the goal of the military-to-civilian transfer process is to establish a baseline, allowing the aircraft to be maintained in a condition for safe operation.