McDonnell Douglas DC-10-30

Photo copyright Richard Vandervord - used with permission

Overseas National Airways Flight 032, N1032F

Jamaica, New York

November 12, 1975

At approximately 1310 Eastern Standard Time on November 12, 1975, Overseas National Airways (ONA) Flight 032, a McDonnell Douglas Model DC-10-30 airplane, crashed while attempting to take off from John F. Kennedy (JFK) International Airport, New York. During takeoff roll on runway 13R, the airplane struck a flock of sea gulls, causing the crew to perform a rejected takeoff. The number 3 engine and several tires and wheels disintegrated, and the landing gear collapsed. A resulting fuel leak led to an extensive ground fire which destroyed the airplane. Of the 128 passengers and 11 crewmembers on board, two people were seriously injured and 30 were slightly injured.

History of Flight

Photo copyright Kenneth C. Iwelumo - used with permission

View Larger

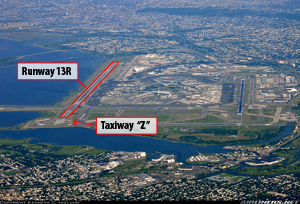

On November 12, 1975, an Overseas National Airways, Inc. (ONA), McDonnell-Douglas DC-10-30 operating as Flight 032, crashed while attempting to take-off from runway 13R at the John F. Kennedy International Airport, Jamaica, New York. It was a non-revenue flight with 128 passengers and a crew of 11, all ONA employees. It had a maximum load of fuel, and the aircraft weight was 556,000 pounds at pushback (Maximum allowable takeoff gross weight was 555,000). The flight crew taxied for 3 miles at 12 miles per hour before reaching the beginning of the runway.

Since the airplane would be at maximum takeoff gross weight at the beginning of the takeoff roll, the captain requested and received permission to use runway 13R. The captain requested 13R because this runway was the longest runway at JFK. At the time of this request, runway 13R was inactive because of wind and noise considerations. ONA flight 32 would be the first airplane to operate from runway 13R on the afternoon of the 12th. It is important to note that runway 13R is adjacent to a saltwater bay and is near the shoreline its entire length.

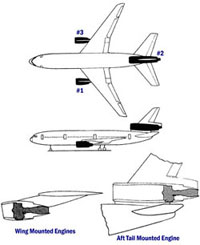

During the take-off roll, after the aircraft passed 100 knots, the captain saw a large flock of birds standing on the runway. The flock became airborne and circled back in front of the approaching airplane. The flight crew heard the birds striking the aircraft, and the captain estimated that the aircraft was struck by about 100 birds. He believed the takeoff decision speed (V1) had not yet been reached, and he rejected the take-off. As the engines went into reverse thrust, the flight engineer stated that they had "lost" the number 3 (wing mounted) engine. The numbers 1 and 2 engines attained normal reverse thrust.

The flight engineer noticed that the number 2 brake system pressure had dropped to zero. The number 2 brake system is powered by the number 3 hydraulic system, which is driven by the number 3 engine. The number 1 brake system pressure remained normal at 3000 psi. The flight engineer advised the captain that the brake system was available.

View Larger

Within seconds, the fire warning light illuminated for the number 3 engine. The flight crew attempted to shut down the number 3 engine by closing the fuel shutoff lever, but the lever could not be moved. The flight engineer then pulled the engine fire handle to shut down the engine, close the fuel shutoff valve, and activate the fire extinguishing units to the engine. The crew estimated that the number 3 engine was shut down within seven seconds after they realized the engine had failed. The engines installed in the aircraft were the General Electric Aircraft Engines (GEAE) CF6-50A model turbofan engines.

Initially, the aircraft seemed to decelerate effectively and the crew believed that it was under control and could be guided safely onto taxiway "Z," the last taxiway at the end of runway 13R, without departing the end of the runway. However, during the turn onto the taxiway, the aircraft left the paved surface before stopping on the shoulder of the taxiway. The crew estimated the aircraft was traveling at approximately 40 knots during the turn onto the taxiway. As the aircraft turned onto taxiway "Z," the right main gear failed, which resulted in the wing hitting the ground, and failure of the right wing rear spar. The spar failure resulted in a failure of the number 3 wing fuel tank, allowing massive fuel leakage to occur. Additionally, when the right wing contacted the ground, the number 3 engine also impacted the ground and was displaced inboard and penetrated the lower wing skin in the area of number 2 wing tank, allowing additional spillage of fuel. The aircraft came to a stop approximately 135 feet from the runway centerline.

View Larger

After the aircraft stopped, the flight crew pulled the fire handles for numbers 1 and 2 engines and closed the engine fuel shutoff levers. The public address microphone had become displaced during the stopping sequence, and an evacuation order could not be given. The first officer opened the right front cockpit window and saw a fire on the right wing. At the same time another crewmember opened the cockpit door and black smoke could be seen in the cabin. The cabin passengers were in the process of emergency evacuation by slides.

The aircraft was consumed by fire. There were no fatalities from this accident. Twenty-seven of the 128 passengers received minor injuries, and six of the eleven crew members received minor or serious injuries, all resulting from the emergency evacuation of the aircraft. The National Transportation Safety Board (NTSB) stated in the ONA Aircraft Accident Report that the rapid and successful egress of all occupants was partially attributed to the fact that nearly all passengers were trained crewmembers and airline employees with knowledge of the aircraft, evacuation procedures, and facilities. The report goes on to state that serious evacuation problems could have been experienced had this been a routine passenger flight with untrained airline passengers.

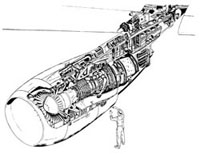

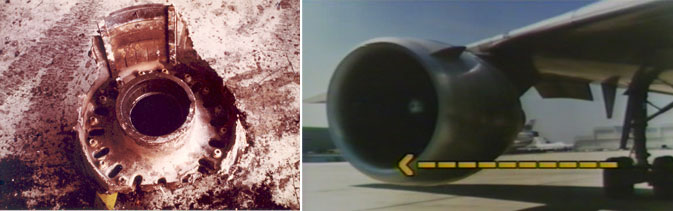

Aircraft wreckage was scattered over an area 1,086 feet wide and 8,460 feet long, the majority being to the right of the runway centerline. Twenty-three great black-backed gull and herring gull carcasses were found scattered across the runway between 6,400 feet and 7,100 feet from the point of break release. One recovered carcass had a wingspan of 66 inches. The largest bird weighed five pounds, and the average weight of the birds was 3 - 4 pounds. Debris from the number 3 engine that was found on the runway included the lower high pressure compressor (HPC) case, the HPC stage 1 and 2 disks, the complete fan module, and miscellaneous parts that included the fuel feed line. A three-foot section of the fan midshaft was located to the right of the runway. The HPC rotor assembly stages 3 through 13 came to rest approximately 900 feet to the left of the runway centerline and caused damage and fire to a Pan American World Airways service shed. The stage 14 HPC disk was not recovered from the accident site.

A detailed disassembly and examination of the number 3 engine occurred at the engine manufacturer as part of the accident investigation process. The NTSB and GEAE ultimately reached different conclusions relative to the precise engine failure sequence and cause of the catastrophic failure of the engine. Examination of the engine hardware indicated this had been a massive uncontained engine failure. Forces associated with the engine failure caused liberation of the inlet cowl, fan cowl, the core cowl, and the thrust reverser. The upper and lower HPC case assemblies had separated from the engine at the circumferential flanges and horizontal split lines.

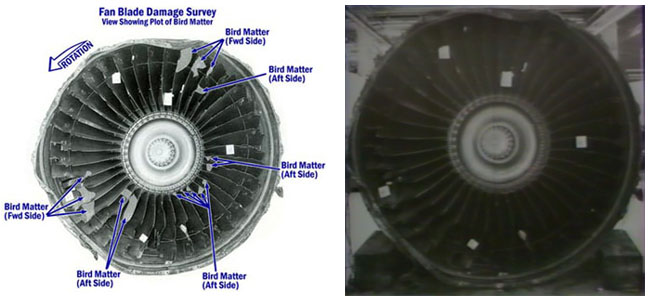

Examination of the number 3 engine also showed evidence of at least six bird strikes on the lip assembly of the engine inlet cowl. Bird feathers and debris were found on fan blades, the fan spinner, and other parts of the engine. View the Fan Rotor Assembly Diagram

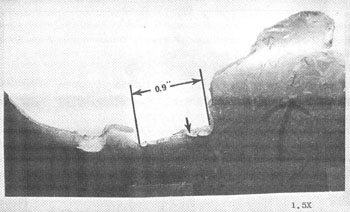

An examination of the fan module revealed two fan blades that had outer portions broken off approximately four inches below the midspan shroud. All fan blades had pieces broken off at leading edges, with varying degrees of panel to tip, and leading edge damage. GEAE and NTSB did not agree on the type of foreign object(s) that initially caused the impact damage to the fan blades.

Great Black-Backed and Herring Gulls

The great black-backed gull is the largest of the gulls. It may weigh between three and four pounds and its wing span can reach 63 inches. It can be identified by its pure white underparts and sooty black wings and back. It is primarily found on the coastal Northeastern part of the U.S. Over the past 100 years, its population has been increasing and expanding southward.

The herring gull is also a large gull (up to 26 inches long, with a wingspan of 54 to 59 inches), and is the best known, or most common of all gulls in North America. Some herring gulls, especially those in colder climates, migrate south in winter, but those along the lower Great Lakes, and on the east coast of the United States tend to be permanent residents. They are common around garbage dumps, and have adapted well to urban life.

It has been noted that gulls are attracted to the ease of finding food at garbage dumps. The proximity of many airports to garbage dumps, in addition to the open spaces at airports, makes it an ideal environment for gulls to congregate. Gulls are slow fliers, so if they loiter at an airport, it increases the probability of collisions with airplanes.

It has been noted that gulls are attracted to the ease of finding food at garbage dumps. The proximity of many airports to garbage dumps, in addition to the open spaces at airports, makes it an ideal environment for gulls to congregate. Gulls are slow fliers, so if they loiter at an airport, it increases the probability of collisions with airplanes.

NTSB Conclusions

By examining the engine hardware, interviewing the flight crew, and reviewing the available evidence, the NTSB concluded the number 3 engine had ingested multiple gulls at high power during the takeoff on runway 13R. The impact of the birds on the fan blades rotating at high rotational speeds resulted in severe damage to the fan blades and loss of fan blade material. The loss of fan blade material (loss of mass) caused a very high fan rotor imbalance of approximately 122,000 gram inches. The NTSB also concluded that the aircraft fire initially started due to debris from the uncontained engine failure fracturing the main fuel line and hot engine parts igniting the raw fuel that was released. The failed tire also made a hole in the wing skin which released fuel.

The NTSB determined the probable cause of this accident to have been the disintegration of, and subsequent fire in, the number 3 engine following ingestion of multiple gulls. Following the engine failure the aircraft failed to decelerate effectively for the following reasons:

- The number 3 hydraulic system was inoperative, which caused the loss of the number 2 brake system and reduced brake torque;

- The number 3 thrust reverser was inoperative;

- At least three tires were failed;

- The number 3 system spoiler panels on each wing could not deploy; and

- The runway surface was wet.

The NTSB further concluded that the flight crew performed exceptionally well executing the aborted takeoff. They completed the rejected takeoff checklist, followed procedures, and when it became apparent they were not going to get the airplane stopped on the runway, they executed a high speed turn onto the taxiway to avoid hitting a blast fence located at the end of the runway.

GEAE Conclusions

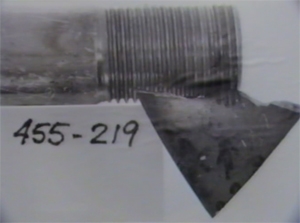

GEAE's failure investigation identified a conclusion that differed from that of the NTSB regarding the initiating event of the engine failure. They believed that debris from a failed main landing gear wheel and tire were ingested into the engine during the takeoff roll, but prior to the engine bird ingestion. GEAE concluded that fragments from the wheel caused extensive hard body impact damage and liberation of blade material that resulted in high fan rotor imbalance.

Photos used with permission of GEAE

Wheel and Tire Failures - GEAE Conclusions

GEAE concluded the birds that were ingested into the number 3 engine did not cause the fan blade damage, and were not a factor in the engine failure. This finding was based on their metallurgical examination of the damaged fan blades, prior service history of the CF6 engine, and previous bird ingestion events. GEAE further concluded that tire material impacted and penetrated the left side of the number 3 engine core cowl, severing an engine fuel manifold line, resulting in a fuel explosion within the engine core compartment.

Photos used with permission of GEAE

Overpressure and Fan Rotor Imbalance - GEAE Conclusions

One aspect of the accident investigation was an examination of the extreme overpressures that developed in the engine and the manner in which the engine failed. GEAE conducted a detailed engineering study of the dynamic loads that result from sudden changes in fan rotor balance due to blade damage. This study included full scale testing of engine structures, and five separate controlled engine tests to understand the root cause of this failure, and define the necessary corrective actions.

GEAE determined by test that a very high fan rotor vibration resulted from the high rotational speeds of the damaged and highly unbalanced fan rotor (i.e., missing fan blade material). The high unbalance caused a shift of the fan rotor center line that resulted in the rotating components of the fan rotor contacting the static, non-rotating components. The fan blade tips and booster (low pressure compressor) blade tips then rubbed very hard into the outer shroud.

- Used with permission of GEAE

During normal engine operation the clearances at the blade tips are very low, to maximize engine efficiency. But in severe unbalance conditions, such as this event, the tips of the rotating blades can rub very hard into the nonrotating outer shrouds. The shrouds are covered by a layer of abradable material. During normal engine operation, the abradable material is intended to rub off into the flow path when there are light rubs of the blade tips against the outer shroud. The No. 3 engine experienced a high unbalance due to the damaged fan rotor that resulted in hard rubs, and the release of large quantities of the pulverized abradable material into the flow path. The pulverized abradable material entered the high pressure compressor where the material was exposed to sufficiently high temperature/pressure conditions to result in the material igniting. This resulted in an overpressure within the compressor section, causing the compressor cases to separate. GEAE's conclusion was that the particular abradable material used in the engine had greater combustibility characteristics at lower operating temperatures than other types of abradable shroud material used in engines.

- Used with permission of GEAE

The NTSB concluded the material ignited explosively and overpressurized the compressor case sections resulting in the case separations and loss of structural integrity of the engine. GEAE's investigation concluded that the pulverized material had ignited in the compressor and partially separated the compressor cases but not with sufficient explosive force to result in loss of structural integrity to the engine. GEAE further concluded that tire debris penetrated the core cowl area and severed a fuel manifold line. The raw fuel in the confined core cowl area ignited and caused the explosive damage to the engine. This damage in combination with the failed compressor case sections resulted in the catastrophic failure of the engine.

Through the detailed engineering study and testing conducted by GEAE as part of the accident investigation, it was believed by GEAE that the pulverized abradable shroud material ignited in the HPC and overpressurized the compressor case. As a result, GEAE identified an alternate abradable material that was shown by a controlled engine test to have acceptable characteristics and not ignite in the compressor section. The alternate material was incorporated into all CF6 production engines, and the FAA issued two Airworthiness Directives mandating the replacement of the old abradable material with the new material for all CF6-6 and CF6-50 series engines that were in revenue service.

View the animation illustrating the engine failure scenarios developed by both the NTSB and GEAE below:

Bird Ingestion and Airport Bird Control

The NTSB issued several safety recommendations highlighting the problems and deficiencies related to airport bird control and the potential hazards of aircraft bird strikes. John F. Kennedy International Airport is located on Jamaica Bay, which had numerous mud and sand flats, swampy islands, and garbage dumps. An area of the airport was also adjacent to a wildlife refuge. There was an established bird control program at JFK Airport to address a recognized bird hazard problem, and at the time of the ONA accident, the FAA was monitoring the program and working with the airport authorities to implement a more aggressive bird hazard reduction program.

The most frequent aircraft/bird encounters have historically occurred during flight operations in or around airports and near the ground. Successfully mitigating the hazards of the bird threat to aircraft incorporates multiple approaches including:

- An aggressive and effective airport bird control program that will reduce the

- number of birds in and around the airport areas;

- Flight crew educational training, awareness, and avoidance procedures related

- to bird threats, and;

- Engine and aircraft designs capable of sustaining substantial bird strike encounters.

Following the ONA accident, the FAA formed a special task force to visit certain airports and obtain information and data on airport bird hazards that were used in developing a national program of bird hazard reporting and alleviation. The FAA also issued a General Notice that was transmitted to all FAA regions to implement a 60-day special emphasis program designed to identify airports having bird problems and to initiate action directed at alleviating the hazards at these airports.

Current Wildlife Management Strategies at JFK

Currently, the Port Authority of NY/NJ takes a multi-tiered approach to wildlife mitigation. This includes habitat modification, wildlife dispersal, daily wildlife patrols, bird monitoring, laughing gull nest surveys, mammal spotlight surveys, insect control, water management, egg-oiling, trapping, and shooting when necessary. Outside agencies have been called for action, when necessary, to help manage the bird population in the vicinity around the airports. The Port Authority has a staff wildlife biologist who assists the Wildlife Supervisors. The Wildlife Supervisors provide around-the-clock airport coverage.

The Port Authority of NY/NJ supplements its internal wildlife management staff with outside contracts for wildlife control such as with USDA-Wildlife Services. Additional resources include JFK's wildlife strike database which dating back to 1979 and is one of the oldest and most comprehensive in the world. It also counts with a long-standing Bird Hazard Task Force, composed of representatives of FAA, USDA-Wildlife Services, National Park Service, U.S. Fish & Wildlife Service, New York State Department of Environmental Conservation, New York City Department of Environmental Protection, and New York City Department of Parks & Recreation. This task force provides suggestions for improving wildlife management practices to reduce bird hazards.

Airports that identify a wildlife issue and its potential hazard to the airport proceed to develop a wildlife management plan. The cognizant authority requests an assessment by a wildlife biologist, who determines the threat and suggests solutions. The airport then develops a plan that address how those threats will be mitigated.

At JFK Airport, the Port Authority of New York is responsible for the bird control program via their Wildlife Management Plan. The plan manages all water, wetlands, habitat, or migratory or permanent population issues. It consists of continuous surveillance of the airport through vehicles and Wildlife Agents. Wildlife Agents regularly inspect the runways and vicinities.

Runway Sweeps at JFK - Current Practice

The Wildlife Supervisor and/or Senior Wildlife Supervisor will conduct daily runway sweeps at or around sunrise. Additional runway sweeps will be conducted by the Wildlife Supervisor or Wildlife Agent as requested by the FAA air traffic control tower (ATCT) or the Airport Duty Supervisor when runways change from inactive to active. During the morning runway sweep, the Wildlife Supervisor will search for carcasses from any unreported wildlife strikes. When a runway opens to aircraft activity from an inactive status, the Wildlife Supervisor or Wildlife Agent must conduct a "bird sweep" to disperse any birds or other wildlife in the area and verify that there are no wildlife hazards on the runway. Carriers and other airport entities are encouraged to report any wildlife problems, so that they are investigated.

Photo source Port Authority of New York and New Jersey – Used with permission

The NTSB determined that the probable cause of this accident was the disintegration of, and subsequent fire in, the number 3 engine following ingestion of multiple gulls.

The NTSB identified 20 findings for this accident in report NTSB-AAR-76-19. The findings addressed the following topics:

- The bird strike and damage to the engine

- The difficulties of stopping the engine because of loss of tire, hydraulic system, and other systems

- The use of flammable material and release of fuel into the fire

- Certification of the CF6-6 engine and the bird ingestion guidelines used

- Bird control system used at JFK

View the detailed NTSB Findings

The NTSB issued a total of 18 safety recommendations in the official results related to this accident. The following is a brief, categorized summary of the safety recommendations:

- Eight of the safety recommendations were related to bird control at airports and their associated hazards to aircraft operations. Some of these recommendations were specific to JFK Airport and other large international airports in the greater New York City area, and others addressed bird hazard reduction programs.

- Six of the safety recommendations were related to the CF6 engine's capability to meet the foreign object ingestion criteria, including the engine bird ingestion criteria, found in Advisory Circular (AC) 33-1A.

- Two of the safety recommendations requested that the FAA review and increase the bird ingestion certification standards for large turbofan engines.

- Two of the safety recommendations were issued on flight attendant seat restraint systems that addressed inadvertent seatbelt release.

The following Federal Aviation Regulations were pertinent to the CF6-50 design and certification:

14 CFR 33.13 - Design Features

The CF6-50A engine was FAA certified on March 23, 1972. Because of the design similarities between the CF6-50A and the CF6-6 engine, the FAA did not require additional ingestion tests during certification. The CF6-6D engine was FAA certified on September 16, 1970, and at the time there were no specific bird ingestion certification requirements, but the subject was addressed by 14 CFR, 33.13.

Advisory Circular 33-1A was issued on June 19, 1968, and included criteria for addressing bird threats and conducting a bird ingestion test. This AC was revised on April 22, 1970, to AC-33-1B to include revised criteria bird ingestion tests for engines.

At the time of this accident, JFK was rapidly expanding and was attempting to balance a number of potentially conflicting interests. The airport serves a large metropolitan area and has high demands for a large traffic volume. The area is also on the seacoast that is habitat to a vast population of wildlife, a significant portion of which is birds of various species. Areas adjacent to the airport are designated as wildlife sanctuaries. Further, much of the airport was constructed on landfill that had previously been refuse collection areas, and active garbage dumps were near airport property. The garbage dumps attract a large number of birds, especially gulls. In order to fulfill the desires of the metropolitan area for convenient and frequent air travel, the airport had to develop a robust wildlife control program in order to prevent accidents between aircraft and wildlife and to also protect the many native wildlife species that reside in the adjacent sanctuary areas.

- The abradable shroud material had greater combustibility characteristics when compared to other types of abradable shroud materials. The material used in the engine could ignite in the high-pressure compressor and result in over pressurization and failure of the compressor case.

- For an airport such as JFK, which had an established bird control program, activation of a runway which had been inactive for a substantial period of time without following the appropriate procedure to determine existence of and/or elimination of hazardous birds on/near the runway surface.

- The abradable shroud material was a suitable material for use in an engine and did not cause a safety threat to the aircraft.

- As long as an airport is fully operational, all runways will be safe from bird hazards, even if some runways have been unused for substantial periods of time.

During the timeframe of the ONA accident, aircraft bird strikes and engine ingestion events were continuing to occur. Some events were serious and resulted in accidents and loss of life. Examples of accidents related to aircraft bird strikes and/or engine bird ingestion included:

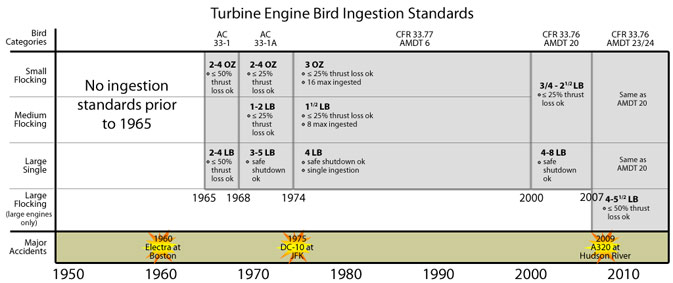

- March 10, 1960, a Lockheed Electra turboprop ingested European starlings into multiple engines during takeoff from Boston Logan Airport, resulting in a multi-engine power loss. The plane crashed into Boston Harbor, killing 62 people. The accident prompted the FAA to initiate action to develop minimum bird ingestion standards for turbine powered engines.

See accident module

- February 26, 1973, Lear 24 struck a flock of brown-headed cowbirds during takeoff. The aircraft crashed and killed seven people. The accident prompted the FAA to initiate action to develop guidelines concerning the location of solid waste disposal facilities on or near airports.

- November 23, 1962, a Vickers-Armstrongs Model Viscount 745D airplane struck at least two whistling swans while taking off from Newark, NJ. All thirteen passengers and all four crewmembers were fatally injured. The probable cause of this accident was determined to be the loss of control following separation of the left horizontal stabilizer which had been weakened by a collision with a whistling swan.

See accident module

Engine Bird Ingestion

The NTSB issued Safety Recommendation A-76-64, related to the bird ingestion threat to engines, and updated the bird ingestion standards for large turbofan engines.

A-76-64 stated:

"Amend 14 CFR, part 33.77 to increase the maximum number of birds in the various size categories required to be ingested into large turbine engines. These increased numbers and sizes should be consistent with the birds ingested during service experience of these engines."

The engine bird ingestion regulatory standards were first incorporated into 14 CFR part 33.77 at Amendment 6, effective in 1974. Based on the above recommendation, the amendment removed section 33.13 and introduced a new section 33.77 on foreign object ingestion that included requirements for ingestion of birds and other foreign objects. The FAA again revised section 33.77 in 1984 at Amendment 10.

The above safety recommendation also led the FAA to sponsor an industry-wide study of the types, sizes, and quantities of birds that had been ingested into engines of all sizes and the resulting effects on engine performance. Subsequently, the FAA requested that the Aerospace Industries Association (AIA) analyze the data and report back to the FAA.

Based on the AIA analysis, the FAA concluded that the bird ingestion standards should be modified to increase the severity of the bird ingestion testing standards for large, high-bypass ratio engines, and that the design and testing requirements for all engine sizes should be updated to reflect the actual numbers and bird sizes being ingested. That effort was adopted as a 14 CFR part 33 and Joint Aviation Regulation engine (JAR-E) harmonization project and selected as an Aviation Rulemaking Advisory Committee (ARAC) project. The revised engine bird ingestion standards were defined in a new 33.76 section and became effective on December 13, 2000, at Amendment 20 to 14 CFR section 33. The FAA also issued AC-33.76 that provides guidance and acceptable methods of compliance with the engine bird ingestion requirements of section 33.76.

The following table highlights the evolution of the turbine engine bird ingestion standards:

View Larger

Airplane Tires, Wheels, and Brakes

A series of accidents and incidents involving large commercial jet airplanes, particularly wide body types in the mid 1970s, involved failures of tires, wheels, brakes, and antiskid devices. The NTSB issued safety recommendations and advisory actions in this time period that addressed the standards, testing, quality control, and operational limits of aircraft tires. The FAA intensified its surveillance efforts with respect to aircraft tires and began an analysis of the failures and potential corrective actions. This led to joint FAA-Industry meetings in 1976 and 1977 that resulted in a proposed set of revised and updated standards and regulations to reflect the latest technology and to meet operating conditions.

Tires/Wheels/Brakes standards and regulations: Amendments 25-49 and 37-46 were issued on November 29, 1979 and improved the Technical Standard Order (TSO) applicable to landing gear main and nose wheel tires and added more comprehensive certification requirements covering tire loads and speed ratings. Amendments 25-48 and 37-45 were issued on November 29, 1979 and revised the TSO standards for aircraft wheels and wheel brake assemblies and related certification requirements for airplane brakes.

Wildlife Management Programs

Several recommendations from the NTSB highlighting the problems and deficiencies related to airport bird control and the potential hazards of aircraft bird strikes. Currently, CFR Part 139 addresses the operational rules for airport. Airports must comply with 14 CFR part139.201 and have an airport certificate manual in order to operate. The manual must include a description of operating procedures, facilities and equipment, responsibility assignments, and any other information needed by personnel concerned with operating the airport. The airport certificate manual must also include information on the airports wildlife hazardous management programs. 14 CFR part139.337 addresses the information required in the Wildlife Hazardous Management Plan which is meant to alleviate immediate wildlife hazards whenever they are detected. The FAA also issued various Advisory Circulars that provides guidance and acceptable methods of compliance for the airport operating rules mentioned above. The AC are the following:

AC 150/5210-22 Airport Certification Manual

AC 150/5200-33B Hazardous Wildlife Attractants On or Near Airports

AC 150/5200-36 Qualification for Wildlife Biologist Conducting Wildlife Hazards Assessment and Training Curriculum for Airport Personnel Involved in Controlling Wildlife Hazards on Airports

The FAA issued the following ADs related to this accident.

Engine:

- AD 76-17-01: This AD became effective on August 20, 1976, and required replacement of the abradable epoxy resin material with an alternate material (aluminum honeycomb) that would not ignite and result in excessive overpressure in the high-pressure compressor. This AD was applicable to CF6-50 series turbofan engines and incorporated by reference GE service bulletin 72-412, Rev 1.

- AD 76-21-04: This AD became effective on November 30, 1977, and required replacement of the abradable material with an alternate material that would not ignite and result in excessive overpressure in the high-pressure compressor. This AD was applicable to CF6-6 series turbofan engines and incorporated by reference GE service bulletin 72-647.

Airplane Life Cycle:

- Design / Manufacturing

- Operational

Accident Threat Categories:

- Bird Hazards

- Uncontained Engine Failure

- Uncontrolled Fire / Smoke

Groupings:

- N/A

Accident Common Themes:

- Flawed Assumptions

Flawed Assumptions

The FAA was monitoring the bird problem at JFK and noticed that there were more bird strikes in early 1975 than in the same period in 1974. A series of meetings were held to discuss solutions. Even with the continuous evolution of the bird hazard control program at JFK, certain deficiencies allowed runway 13R to be declared active without proper bird clearing procedures being conducted.

Lockheed Electra L-188

March 10, 1960, a Lockheed Electra turboprop ingested European starlings into multiple engines during takeoff from Boston Logan Airport resulting in a multi-engine power loss. The plane crashed into Boston Harbor, killing 62 people. The accident prompted the FAA to initiate action to develop minimum bird ingestion standards for turbine powered engines.

See accident module

Lear 24

February 26, 1973, a Lear 24 struck a flock of brown-headed cowbirds during takeoff. The aircraft crashed and killed seven people. The accident prompted the FAA to initiate action to develop guidelines concerning the location of solid waste disposal facilities on or near airports.

Vickers-Armstrongs, Model Viscount 745D

November 23, 1962, a Vickers-Armstrongs Model Viscount 745D airplane struck at least two whistling swans while taking off from Newark, NJ. All thirteen passengers and all four crewmembers were fatally injured. The probable cause of this accident was determined to be the loss of control following separation of the left horizontal stabilizer which had been weakened by a collision with a whistling swan.

See accident module

Technical Related Lessons:

Airports with identified bird hazards should effectively use the procedures in their bird hazard control programs in order to confirm that a runway is safe to begin operations. A runway that has been inactive for a substantial period of time must be determined to be clear of birds, prior to directing airplanes to use that runway. (Threat Category: Bird Hazards)

- ONA Flight 032 was taking-off from runway 13R, a nonconforming runway, at the time of the accident. A nonconforming runway is one that is not being used as an active runway because of wind and noise considerations. The captain had requested runway 13R because of weight considerations. During the take-off roll, the captain saw a flock of birds that rose from the runway, separated, and then regrouped in front of the aircraft.

- Prior to the accident, JFK International Airport had an existing bird reduction program that included carbide cannons, vehicles capable of transmitting tape-recorded stress cries of birds, bird patrols with shotguns, and removal of bird attractants such as water ponds, vegetation, and rodent life. The NTSB concluded that at the time of the ONA Flight 032 accident, JFK airport did not effectively control the bird hazard at the airport with the established program and had failed to conduct a "bird sweep" of the runway with an airport vehicle prior to permitting the ONA DC-10 to depart.

Foreseeable engine failures which result in significant engine imbalance should not result in uncontained engine failure. (Threat Category: Uncontained Engine Failure)

- ONA Flight 032 had a massive uncontained engine failure as a result of foreign object ingestion. GEAE engine CF6-50 was certified to 14 CFR 33.13, which prohibited a design feature that would be hazardous or unreliable to the engine. Compliance was based on similarity with data from previous tests on the CF6-6. Testing for the CF6-6 included ingestion of birds per AC 33-1A and consideration of the engine's critical areas. Since this accident, the engine certification standards have been revised to incorporate additional requirements on foreign object ingestion and expected engine behavior. Expected fan damage and resulting imbalance should not result in engine case rupture, and uncontained engine failure.

An uncontained engine failure during ground operation, which results in a rejected take-off and a fuel tank breech, poses an extreme fire hazard. (Threat Category: Uncontained Engine Failure)

- As a root cause of this accident, the number 3 engine failed and caught fire. The uncontained engine failure combined with unrestricted fuel leakage from multiple sources, including the main fuel tank of the DC-10, led to post-accident ground fire and destruction of the airplane.

Common Theme Related Lessons:

Individual details of comprehensive safety programs need to be continuously reviewed, and shortcomings identified to mitigate potential vulnerabilities. (Common Theme: Flawed Assumptions)

- The FAA was monitoring the bird problem at JFK and noticed that there were more bird strikes in early 1975 than in the same period in 1974. A series of meetings were held to discuss solutions. Even with the continuous evolution of the bird hazard control program at JFK, certain deficiencies allowed runway 13R to be declared active without proper bird clearing procedures being conducted.