Avions de Transport Regional 72-212

Simmons Airlines American Eagle Flight 4184, N401AM

Roselawn, Indiana

October 31, 1994

On October 31, 1994, at 1559 Central Standard Time, an Avions de Transport Regional, Model 72-212 (ATR-72), registration number N401AM, crashed during descent after uncommanded roll excursions and a loss of control. The aircraft was leased to and operated by Simmons Airlines, Incorporated, and doing business as American Eagle Flight 4184.

Prior to the approach into Chicago, Illinois (ORD), the airplane was in a holding pattern in icing conditions, and it was descending with the autopilot engaged to a newly assigned altitude of 8,000 feet when an uncommanded roll excursion occurred. The initial roll excursion and subsequent loss of control were precipitated by an airflow separation forward of the ailerons and uncommanded aileron deflection resulting from an aileron hinge moment anomaly.

The airplane was destroyed by impact forces, and the flight crew of four (captain, first officer and two flight attendants) and 64 passengers received fatal injuries.

History of Flight

Flight 4184 departed Indianapolis, Indiana (IND) at 1455 local time for a planned 45-minute flight to Chicago O'Hare International Airport (ORD). The final cruise altitude was 16,000 feet. At 1513, Flight 4184 began a descent to 10,000 feet. Pilot reports in the vicinity of Flight 4184 indicated that icing conditions were present. After leveling off at 10,000 feet the crew was instructed by air traffic control (ATC) to hold. The first holding pattern was flown at approximately 175 knots indicated airspeed (KIAS) with the wing flaps in the retracted position. There was a discussion in the flight deck of the high deck angle (angle of the cabin floor relative to the airplane flight path). At 1533 the flaps were extended to the 15-degree position and deck angle decreased to approximately 0 degrees. At 1541:07 the flight data recorder (FDR) recorded activation of the airframe deicing system. At 1556:16 the crew was instructed to descend and maintain 8,000 feet.

At 1557:33, as the airplane was descending through 9,130 feet, the angle of attack (AOA) increased through 5 degrees, and the ailerons began deflecting to a right wing down (RWD) position. About one half second later, the ailerons rapidly deflected to 13.43 degrees RWD and the autopilot disconnected. The airplane rolled rapidly to the right, and the pitch attitude and AOA began to decrease.

Within several seconds of the initial aileron and roll excursion, the AOA decreased through 3.5 degrees, the ailerons moved to a nearly neutral position, and the airplane stopped rolling at 77 degrees RWD. The airplane then began to roll left toward a wings-level attitude, and the elevator began moving in a nose-up direction. The AOA began increasing, and the pitch attitude stopped at approximately 15 degrees nose down.

At 1557:38, as the airplane rolled back to the left through 59 degrees RWD (towards wings level), the AOA increased again through 5 degrees and the ailerons again deflected rapidly to a RWD position. The captain's nose-up control column force exceeded 22 pounds, and the airplane rolled rapidly to the right at a rate in excess of 50 degrees per second.

- NTSB Docket Photo

According to FDR information, the captain's nose-up control column force decreased below 22 pounds as the airplane rolled through 120 degrees, and the first officer's nose-up control column force exceeded 22 pounds just after the airplane rolled through the inverted position (180 degrees). Nose-up elevator inputs were indicated on the FDR throughout the roll, and the AOA increased when nose-up elevator increased. At 1557:45 the airplane rolled through the wings-level attitude, completing the first full roll, and the first officer's nose-up control column force decreased below 22 pounds. The nose-up elevator and AOA then decreased rapidly, the ailerons immediately deflected to 6 degrees left wing down (LWD) and then stabilized at about 1 degree RWD. The airplane stopped rolling at 144 degrees RWD.

- NTSB Docket Photo

At 1557:48, as the airplane began rolling left, back towards wings level, the airspeed increased through 260 knots, the pitch attitude decreased through 60 degrees nose down, vertical acceleration fluctuated between 2.0 and 2.5 G, and the altitude decreased through 6,000 feet. At 1557:51, as the roll attitude passed through 90 degrees continuing towards wings level, the captain applied more than 22 pounds of nose-up control column force, the elevator position increased to about 3 degrees nose up, and pitch attitude stopped decreasing at 73 degrees nose down. Airspeed increased through 300 KIAS, vertical acceleration remained above 2 G, and the altitude decreased through 4,900 feet.

The last recorded data on the FDR occurred at an altitude of 1,682 feet, with a vertical speed of approximately 500 feet per second, an indicated airspeed of 375 knots, and a pitch attitude of 38 degrees nose down with 5 degrees of nose-up elevator. During this period the aircraft was experiencing a vertical acceleration of 3.6 G.

The airplane impacted a field, partially inverted, in a nose down, left wing-low attitude. The accident occurred during daylight hours; however, there were no witnesses to the impact.

Ice Protection System

The ATR 72 was certified for operation in icing conditions as specified in Appendix C to 14 CFR part 25, specifically, 14 CFR 25.1419. Certification testing involved flights in natural icing conditions and with artificial ice shapes installed on the airplane.

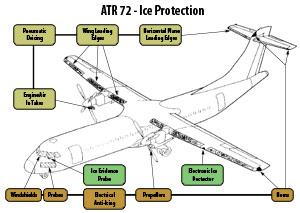

View Larger

The ATR 72 ice protection system includes pneumatic deicing boots for the wing and horizontal stabilizer leading edges and engine air intakes. The system is optional on the vertical stabilizer. A thermal anti-icing system that uses electricity to generate heat protects propeller blades, windshields, pitot/static tubes, static ports, angle of attack and total air temperature sensors as well as the balance horns for the aileron, elevator, and rudder.

The pneumatic boot system protecting the wings, tail, and engine inlet surfaces operates on engine bleed air and is intended to remove ice that forms on the protected surfaces by inflating the rubber boots. Engine bleed air operating through flow control valves causes the boots to cyclically inflate and deflate. When the boots inflate, accumulated ice is cracked and removed by the airstream.

The system is controlled by a timer select switch and a cycle switch, both located in the flight deck. The cycle switch is a two-position switch selectable for FAST and SLOW. In the FAST mode the boots automatically cycle every minute and in the SLOW mode the boots are cycled every three minutes.

View information on icing certification programs and ice protection systems.

Supercooled Large Droplets

The Roselawn accident occurred in freezing drizzle conditions. Freezing drizzle and freezing rain are known collectively as Supercooled Large Droplets (SLD). SLD icing is a rare and very severe condition. NASA Glenn Research Center produced a video on SLD icing.

The entire NASA video is 26 minutes in length. Ten and a half minutes of excerpts from the video are also available in this module.

View the Supercooled Large Droplet Icing (SLD) - Full Length Video below:

View the SLD Overview and the NTSB animation of the accident Video below:

Relationship of SLD and the Part 25 Icing Certification Envelopes

14 CFR part 25, Appendix C defines an atmospheric envelope, describing certain icing threat categories which must be considered during the certification process of transport airplanes. Very little was known regarding SLD conditions at the time that research was being conducted leading to the creation of the Appendix C icing envelope. Therefore, SLD icing conditions were not included as part of the Appendix C envelope.

View the NASA Icing Certification Envelopes Video below:

the leading edge ice protection equipment (shown in black)

SLD Ice Accretions

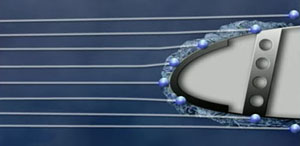

The chord-wise extent of the wing deicing boots on the ATR-72, while sufficient for part 25, Appendix C icing conditions, was determined by the investigation to have been inadequate to protect against the supercooled large droplet (SLD) icing conditions encountered by the accident airplane. The aft extent of ice protection systems is typically designed based on the impingement behavior of 40-micron (40 x 10 -6 meters) droplets. SLD droplets are greater than 50 microns, and due to their mass tend to impinge further aft on an airfoil than a 40-micron droplet.

View the Impingement Limits NASA Video below:

Performance and Handling Qualities

On the accident airplane, SLD conditions resulted in the formation of ice beyond the trailing edge of the deicing boot. Activation of the deicing boots then removed a portion of the ice, leaving an ice ridge aft of the boot trailing edge. The presence of this ice ridge resulted in a degradation of airplane performance and handling qualities.

View the Performance and Handling NASA Video below:

Visual Cues and Airplane Flight Manual (AFM) Limitations for Severe Icing

The ATR 72 is equipped with unpowered roll controls and pneumatic deicing boots. This combination of control features and pneumatic boots was concluded by the investigators to be particularly susceptible to the effects of SLD contamination. Consequently, the FAA issued Airworthiness Directives (ADs) for airplanes with these design features. Airplanes equipped with unpowered roll controls are a particular concern. The flight crew must use their own strength to move the control surfaces and they do not have the benefit of a hydraulic system to react to uncommanded motion of those surfaces.

The ADs provided generic visual icing cues for, and procedures for exiting from, severe icing conditions, and limit or prohibit the use of various flight control devices. "Severe icing" is terminology used to describe icing conditions that exceed the capabilities of the ice protection equipment. The term "severe icing" was used in these AD's in lieu of "SLD," "freezing rain," or "freezing drizzle," because it is commonly used and understood within the transport pilot community.

Severe icing visual cues include:

- Unusually extensive ice accreted on the airframe in areas not normally observed to collect ice

- Accumulation of ice on the wing aft of the protected areas

- Accumulation of ice on the propeller spinner further aft than normally observed

Photo (right) is an example of the on the wing aft of the protected areas. This may be visible to the flight crew on a high-wing airplane.

View the SLD Cues from the Airworthiness Directives NASA Video below:

AFM limitations required by the ADs included:

in conditions within the icing certification envelope

Limitation on Autopilot Use:

- Since the autopilot may mask tactile cues that indicate adverse changes in handling characteristics, use of the autopilot was prohibited by the ADs when any of the three previously described visual cues exist.

the wing. In this case because of the angle of attack, the ice does not appear to extend on the wing aft of the protected area.

Photographs by permission of SAAB.

Limitation on the Use of Flaps:

- Flap extension during extended operation (e.g., holding) in icing conditions was prohibited by the ADs. Operation with flaps extended can result in a reduced wing angle-of-attack, with the possibility of ice forming on the upper surface further aft on the wing than normal, and possibly aft of the protected area.

- If the flaps were extended prior to entering icing, procedures advised against flap retraction until the airframe is clear of ice.

The ADs also provided procedures such as:

- Avoiding abrupt and excessive maneuvering that may exacerbate control difficulties

- Not engaging the autopilot

- If the autopilot is engaged, hold the control wheel firmly while disengaging the autopilot

When and Where to Expect SLD

View the "When and Where" to expect SLD NASA Video below:

Severe Icing Definition

The NTSB was concerned that 14 CFR part 91, § 91.527, part 135, § 135.227 and Advisory Circular (AC) 91-74 "Pilot Guide-Flight In Icing Conditions" implied authorization for flight into severe icing conditions. The NTSB felt that the wording which stated:

"Except for an airplane that has ice protection provisions that meet the requirements in section 34 of Special Federal Aviation Regulation (SFAR) No. 23 (for § 91.527) or section 34 of appendix A (for §135.227) or for transport category airplane type certification, no pilot may fly an airplane into known or forecast severe icing conditions"

implied authorization to fly in severe icing conditions if the aircraft were equipped as per the applicable SFAR or appendix.

To address the NTSB concern, AC 91-74 "Pilot Guide-Flight In Icing Conditions" was revised on December 31, 2007. This revision includes clarification of the definition of severe icing, and provides guidance for immediately exiting severe icing conditions for flight operations conducted under all operational rules contained in 14 CFR parts 91, 121, 125, and 135.

The revised definition of severe icing in AC 91-74A is:

"Severe Icing - The rate of ice accumulation is such that ice protection systems fail to remove the accumulation of ice and ice accumulates in locations not normally prone to icing, such as areas aft of protected surfaces and any other areas identified by the manufacturer. Immediate exit from the condition is necessary."

AC 91-74A also contains the following:

"Note: Even airplanes approved for flight into known icing conditions should not fly into severe icing. Many Airplane Flight Manual Limitations Sections require an immediate exit when these types of conditions are encountered."

The FAA published SAFO 06016, 14 CFR Parts 91 and 135, In-flight Icing, Turbopropeller Airplanes, on November 1, 2006. The SAFO:

- Provides cues for icing recognition;

- Provides information on the use of ice protection systems; and

- Clarifies autopilot operational procedures.

The FAA also published SAFO 08006, 14 CFR Parts 91 and 135, Flight Into Known or Forecast Severe Icing Conditions, on January 25, 2008. The SAFO:

- Clarifies the definition of severe icing and emphasizes the need to immediately exit severe icing conditions when encountered;

- Serves to increase pilot awareness of the dangers associated with flight in severe icing conditions; and

- Emphasizes the importance of following Airplane Flight Manual (AFM) limitations and procedures established covering encounters with these conditions.

The NTSB issued 43 findings relative to this accident. The majority of the findings addressed inadequate icing certification regulations, lack of certification oversight by the FAA and/or DGAC, insufficient bilateral communication during certification of both the ATR-42 and -72, and inadequate flight crew information on aileron hinge moment reversals and recovery techniques. View the NTSB findings.

You may view any of these documents by selecting the links below.

- NTSB Report. NOTE: This is Volume I of the NTSB report. Revisions to the report are identified on pages a-1 through a-3. The revisions are not incorporated in the body of the report.

- DGAC Petition for Reconsideration. NOTE: This document is Volume II of the NTSB report. The DGAC petition begins on page 5. This document includes input from the Bureau d'Enquêtes et d'Analyses (BEA) which is France's accident investigatory organization. BEA was invited to participate in the investigation by the NTSB because the ATR-72 is a French-manufactured aircraft.

The NTSB revised probable cause position is as follows:

"The National Transportation Safety Board determines that the probable cause of this accident was the loss of control, attributed to a sudden and unexpected aileron hinge moment reversal, that occurred after a ridge of ice accreted beyond the deice boots while the airplane was in a holding pattern during which it intermittently encountered supercooled cloud and drizzle/rain drops, the size and water content of which exceeded those described in the icing certification envelope. The airplane was susceptible to this loss of control, and the crew was unable to recover."

There were several petitions for reconsideration and comments from the principal parties to the accident. Those documents may be viewed at the following links:

- ATR Petition for Reconsideration

- FAA Comments

- Air Line Pilots Association Comments

- Full NTSB Response to Petitions for Reconsideration

The NTSB did not adopt the BEA position that the probable cause included the airplane being operated close to the maximum flap extended speed (VFE) and utilizing a 15-degree flap holding configuration not provided for by the Aircraft Operating Manuals. View the probable cause proposed by BEA.

Operation with flaps extended can result in a reduced wing angle-of-attack, with the possibility of ice forming on the upper surface further aft on the wing than normal, possibly aft of the protected areas. The FAA agreed with the significance of operating the airplane with flaps extended in icing conditions and subsequently issued Airworthiness Directive's (ADs) limiting the use of flaps in icing conditions.

The NTSB found that the 14 CFR part 25, Appendix C icing envelope does not include SLD icing conditions; thus, the current process by which aircraft are certified using the Appendix C icing envelope is inadequate and does not require manufacturers to sufficiently demonstrate the airplane's capabilities in all the possible icing conditions that can and do occur.

The BEA issued 39 findings. View the BEA findings. The BEA findings focused on improper crew procedures and a lack of ATC oversight as contributing factors to the accident. BEA also found that operators had been provided with appropriate and adequate instructions regarding aircraft operations in freezing precipitation based on what was known prior to the Roselawn accident.

Both investigating bodies did agree that certificating authorities and the aviation industry in general did not sufficiently recognize freezing drizzle characteristics and its potential effect on aircraft performance and controllability.

The FAA submitted comments to the NTSB on the DGAC petition for reconsideration. The FAA submission covered three areas where they did not concur with the DGAC petition items included in the NTSB report. View the FAA Comments.

The NTSB issued 35 recommendations to the FAA and American Eagle. View the recommendations.

Recommendations to the FAA addressed multiple issues. These included oversight of air carrier operational policies/procedures relative to hazardous in-flight weather, associated crew documents (AFM, AOM), icing research and dissemination of information to the industry, icing certification practices and regulations, FAA internal communications (Certification to/from Flight Standards), bilateral certification processes, and a recommendation to specifically review the certification of the ATR-42 and -72 and issue limitations regarding operations in icing conditions similar to those encountered by the accident aircraft.

The BEA, in general, agreed with the NTSB recommendations. However, they noted a "great disparity" between the broad scope of the NTSB recommendations and the "selective focus" of the NTSB findings and probable cause. In their recommendations the BEA made the following comment regarding the NTSB report:

"It is significant that the Report recommends that the FAA evaluate the need to make observance of the sterile cockpit rule mandatory for air carriers when their aircraft are holding in icing conditions regardless of altitude, and recommends that AMR Eagle 'encourage' its Captains to observe a sterile cockpit environment in icing conditions.

These recommendations are in sharp contrast with the Report's incorrect 'findings' that the gross distractions of this flight crew and the Captain's departure from the cockpit in known icing conditions 'did not contribute to this accident.'"

BEA suggested that the NTSB recommend that the FAA take steps to emphasize that the "sterile cockpit rule" applies to all critical phases of flight, and that a critical phase of flight includes all operations in known icing conditions, regardless of altitude. View BEA recommendations.

The sterile cockpit rule (§121.542) prohibits activities that could distract any flight crewmember from the performance of their duties during critical phases of flight. It also prohibits performance of duties during a critical phase of flight except those required for safe operation of the aircraft. The critical phases of flight are defined as all ground operations involving taxi, takeoff, and landing, and all other flight operations conducted below 10,000 ft., except cruise flight.

The NTSB did not revise their recommendation as suggested by BEA. However, the NTSB did revise their findings by deleting the sentence, "Neither the flight attendant's presence in the cockpit nor the flight crew's conversations with her contributed to the accident."

14 CFR, § 25.21(g) - Proof of compliance

Identifies subpart B requirements that must be met in icing conditions, if certification for flight in icing conditions is sought.

14 CFR, § 25.1419 - Ice Protection

The airplane must be able to safely operate in icing conditions defined in appendix C if certification for flight in icing conditions is sought.

14 CFR, Part 25, appendix C - Part I- Atmospheric Icing Conditions and Part II- Airframe Ice Accretions for Showing Compliance with Subpart B.

Appendix C, part I identifies continuous maximum and intermittent maximum icing conditions.

Appendix C, part II identifies airframe ice accretions that must be used for showing compliance with Subpart B, performance and handling qualities requirements.

14 CFR, § 121.542 - Flight Crewmember Duties

Restricts flight crew's duties and activities during critical phases of flight.

A prevailing cultural/organizational factor that played a role in this accident was the incorrect belief by flight crews that an airplane certificated for flight in icing can safely operate in all icing conditions. As indicated by the NTSB, wording in 14 CFR, § 91.527 (which states that unless the airplane is equipped with approved ice protection, no pilot may fly an airplane into known or forecast severe icing conditions) may be interpreted to allow flight in severe icing conditions and may have contributed to this prevailing belief.

Flight crews operating airplanes equipped with unpowered roll controls and pneumatic deicing boots without information to determine:

- When the airplane is operating in severe icing conditions, which have been shown to be unsafe, and for which the airplane is not certificated

- What action to take when severe icing conditions are encountered

- An airplane certificated for flight in icing can safely operate in all icing conditions

- Holding at Flaps 15 in icing conditions, with no approved procedure, was safe

The ATR-72 and ATR-42 are basically the same airplane, with the ATR-72 having a longer fuselage and a higher gross weight. Since the airplanes are so similar, some incidents or accidents involving an ATR-42 can be relevant to the ATR-72. There were five pre-Roselawn ATR-42 incidents that occurred in severe icing conditions. There was disagreement between the NTSB and the FAA regarding whether Roselawn should have been foreseeable based on these previous incidents of roll instability in severe icing conditions.

The five incidents involving the ATR-42 were:

- Mosinee, Wisconsin, December 22, 1988

- Indian Ocean, April 17, 1991

- Brecon, South Wales, United Kingdom, August 11, 1991

- Newark, New Jersey, March 4, 1993

- Burlington, Massachusetts, January 28, 1994

An FAA letter to the NTSB analyzes these incidents and concludes that the Roselawn accident was not foreseeable because:

- The roll anomalies in all of the pre-Roselawn ATR-42 incidents were induced by a stall, not by an aileron hinge moment anomaly as occurred during the Roselawn ATR-42 accident

- Unlike the Roselawn accident there was no evidence of higher-than-normal control wheel forces in the pre-Roselawn incidents

Following the Roselawn accident, the FAA initiated a three-phase safety review of aircraft operating characteristics during in-flight icing. The first phase focused on the accident airplane and resulted in an airplane modification to minimize the possibility of similar accidents. During the second phase, aircraft similar to the accident airplane were evaluated to determine if uncommanded aileron movement and unacceptable control wheel forces would occur if ice accreted aft of the protected area of the wing. The third phase consisted of a review of in-flight aircraft icing safety and the determination of changes that could be made to increase the level of safety.

Phase I - Special Certification Review, ATR-42/72

Subsequent to the accident involving Flight 4184, the NTSB recommended that the FAA conduct a Special Certification Review (SCR) of Model ATR-42 and -72 series airplanes. The NTSB also recommended that flight tests and/or wind tunnel tests be conducted as part of that review to determine the aileron hinge moment characteristics of the airplanes while operating at different airspeeds and in different configurations during ice accumulation and with varying AOA following ice accretion.

The ATR-72 was flown in freezing drizzle conditions produced by the United States Air Force (USAF) NKC-135A icing tanker. Tests confirmed that a ridge of ice can form aft of the deicing boots.

Subsequent aircraft flight tests in dry air with artificial ice shapes based on the ice shapes formed during the icing tanker tests resulted in roll control anomalies that nearly replicated the Roselawn accident profile.

Aerospatiale developed a modification for the ATR-42 and -72 that increased the chord-wise coverage of the active portion of the upper surface of the outer wing deicing boot (seen in the picture on the left). The FAA required installation of these deicing boot modifications.

Phase II - Fleet Review

Photograph by Embraer - used with permission

In March 1995 the FAA requested other airworthiness authorities and airplane manufacturers to review certain airplanes to determine if they might also experience control difficulties should a ridge of ice form aft of the deicing boots and forward of the ailerons.

The investigation addressed part 23 and part 25 airplanes equipped with pneumatic deicing boots and non-powered flight control systems used in regularly scheduled passenger service in the United States (U.S.).

Most manufacturers complied with the request by performing high-speed taxi tests with one-inch quarter round shapes located aft of the deicing boots and forward of one aileron, to simulate a worst case SLD build up. The control wheel forces obtained during these tests were then extrapolated to forces that would occur at holding speed.

All airplanes examined were found to have acceptable roll control forces [less than the 60-pound limit specified in 14 CFR part §25.143 (Amendment 25-42)].

Two models, the EMB-120 Brasilia and the SAAB 2000 were tested by flying the airplanes in simulated SLD conditions produced by the USAF icing tanker.

and the view of the USAF icing tanker and spray from the EMB-120 flight deck (right)

Photographs by Embraer - used with permission

Phase III - Regulatory Development

In May 1996 the FAA sponsored an International Conference on Aircraft Inflight Icing. At the conference, recommendations were made regarding the need for improvements intended to increase the level of safety of aircraft operations in icing conditions. An FAA Steering Committee was established to review the conference recommendations and develop a comprehensive multi-year FAA In-flight Aircraft Icing Plan.

The plan, published in April 1997, described various activities including rulemaking, development and revision of advisory material, research programs, and other initiatives that had already started or would be undertaken.

View the FAA In-flight Aircraft Icing Plan.

In accordance with this plan, on July 23, 1997, the FAA issued a memorandum, and an issue paper detailing the requirements to evaluate an airplane's susceptibility to roll upset should the airplane be exposed to certain severe icing conditions.

View the issue paper on Roll Control in Supercooled Large Droplet Conditions (4 pages).

In accordance with the FAA In-flight Icing Plan, an Aviation Rulemaking Advisory Committee (ARAC) was tasked on November 24, 1997 to define an icing environment that includes SLD, and devise requirements to assess the ability of aircraft to safely operate either for the period of time to exit, or to operate without restriction in SLD. ARAC was also tasked to address mixed phase conditions if such conditions are determined to be more hazardous than the liquid phase icing environment. View the tasks published in the Federal Register.

Proposals for SLD, mixed phase, and glaciated icing conditions rulemaking were forwarded to the FAA by ARAC in November 2005. The proposal includes a new 14 CFR 25.1420 regulation, a new 14 CFR 25, Appendix X, and a new CFR 33, Appendix D. In addition, revisions to §§25.773, 25.903, 25.929, 25.1093, 25.1323, 25.1325, 33.68, 33.77, and to 14 CFR 25, subpart B - Flight are proposed. View the letter to the FAA and view the ARAC recommended rulemaking. NOTE: There is a typographical error in the letter to the FAA dated March 7, 2005. The letter was actually signed on March 7, 2006.

The ARAC recommended 14 CFR 25.1420 regulation requires that the airplane must be capable of one of the following:

- Operating safely in SLD

- Operating safely in a portion of SLD, detecting when the portion has been exceeded, and operating safely while exiting all icing if the portion is exceeded

- Detecting Appendix X and operating safely while exiting all icing. (The proposed new Appendix X specifies SLD icing conditions that must be considered)

In addition to these actions, in July 1996 the FAA issued Advisory Circular 91-51A, Effect of Icing on Aircraft Control and Airplane Deice and Anti-Ice Systems. View AC 91-51A.

In December 2007 the FAA, in an action coordinated with the NTSB, revised Advisory Circular 91-74 to become AC 91-74A, Pilot Guide: Flight in Icing Conditions in order to clarify ambiguities related to operations in severe icing conditions. This was considered an acceptable alternative response to NTSB recommendation A-96-060.

In July 2008 the FAA also modified Airline Transport Pilot (ATP) and Type Rating Airman Practical Test Standards to now require examiners to test pilots' knowledge in recognizing wing contamination, operating in icing conditions and the importance of crew resource management (CRM) during operations in icing conditions.

Finally, in response to the 1997 ARAC recommendation, in January 2015, the FAA issued amendment 40 to 14 CFR part 25. This amendment adopted 14 CFR 25.1420. The Federal Register notification of the final rule is available at the following link: (25.1420 Federal Register Notification). The new rule was made applicable to airplanes with a maximum certified takeoff weight of less than 60,000 pounds, or airplanes with reversible control systems, regardless of weight. The complete text of the regulation is available at the following link: (14 CFR 25.1420 Supercooled large drop icing conditions).

The FAA also issued Appendix O to 14 CFR part 25. This appendix defines supercooled large droplet icing conditions, as well as the accretion levels that must be demonstrated for compliance with the regulation. Appendix O is available at the following link: (Appendix O).

In addition to the ATR-42 and -72 AD listed under Phase I of the Icing Safety Review, the FAA issued ADs that were applicable to airplanes of a design similar to the ATR. The FAA determined that flight crews operating airplanes equipped with unpowered roll controls and pneumatic deicing boots must be provided with information to determine:

- When the airplane is operating in severe icing conditions, which have been shown to be unsafe, and for which the airplane is not certificated; and

- What action to take when such conditions are encountered.

In support of that finding the FAA issued ADs applicable to 27 different models of part 23 and part 25 airplanes, including the ATR- 42 and -72. One typical AD is AD 96-09-20, issued April 24, 1996. View the AD.

Airplane Life Cycle:

- Design / Manufacturing

- Operational

Accident Threat Categories:

- Inclement Weather / Icing

- In-flight Upsets

Groupings:

- Loss of Control

- Automation

- Approach and Landing

Accident Common Themes:

- Flawed Assumptions

Flawed Assumptions

14 CFR part 25 airplanes approved for flight in icing must demonstrate that they can be safely operated in the icing conditions defined in part 25, Appendix C. Appendix C defines maximum continuous and maximum intermittent icing conditions in terms of liquid water content, droplet diameter, temperature, and horizontal extent of the icing clouds. Appendix C was designed to include 99% of icing encounters. Therefore, 1 in 100 icing encounters will be more severe than Appendix C, some of which will include SLD conditions. Until the Roselawn ATR-72 accident, the design standard of Appendix C was considered to result in aircraft with sufficient inherent margins to be able to safely operate without restrictions in all icing conditions. Service history has shown that the majority of large transport airplanes in airline service today do have these inherent margins. Airplanes with unpowered flight control systems and pneumatic boot ice protection systems have been shown to be particularly vulnerable to severe icing conditions such as SLD.

Comair Flight 3272 EMB-120RT

On January 9, 1997, an Embraer EMB-120RT, N265CA operated by COMAIR Airlines, Inc. as Flight 3272 from the Cincinnati/Northern Kentucky International Airport crashed during approach following an uncommanded roll excursion and rapid descent near Monroe, Michigan. All 26 passengers and three crew members were killed. The airplane was destroyed by ground impact forces and post-accident fire. The NTSB determined that a combination of ice accumulation on the wings and low airspeed with flaps retracted resulted in adverse effects on both lift and drag, leading to a loss of control after automatic disconnection of the autopilot. The airplane entered an extreme nose-down pitch attitude from which the crew was not able to recover.

See accident module

Technical Related Lessons

Supercooled large water droplets, known as SLD, can pose an atmospheric icing hazard to aircraft. Although SLD conditions are rare, when an airplane encounters SLD conditions, it is critical for the flight crew to recognize these conditions and initiate flight path changes to avoid and/or escape the hazard. (Threat Category: Inclement Weather/Icing)

- At the time of this accident there was limited understanding of SLD icing conditions within the aviation industry. SLD icing conditions may overwhelm an airplane's ice protection systems and can result in airplane handling problems. Airplanes equipped with unpowered roll controls and pneumatic deicing boots have been found to be particularly vulnerable to the effects of these conditions. Flight crews for these types of airplanes have been provided with information regarding visual cues for determining when they are in severe icing and procedures for exiting these conditions.

Common Theme Related Lessons

Environmental standards (e.g., hail, rain, birds, gusts, etc.) for large commercial airplane designs must be very conservative. However, extreme environmental conditions can exist which are able to exceed the capabilities of any airplane, or engine, to operate safely. Recognizing that these extreme conditions can exist, a robust environmental standard, in combination with operational strategies, such as avoidance, early recognition, and escape, should also be employed for all aircraft. (Common Theme: Flawed Assumptions)

- At the time of this accident, it was widely assumed that approval to operate in icing conditions allowed operation in icing of any severity, and ice protection systems would be capable of preventing/removing any ice formation that could potentially threaten the airplane. It was clear following this accident that to address the "worst case" icing threat would not be technically feasible and was beyond the "state of the art" for some classes of airplanes. This same feasibility consideration exists for other environmental standards such as bird threats, lightning protection, windshear, hail, water ingestion, turbulence, gusts, etc., where "state of the art" environmental protection strategies alone may not be able to completely mitigate the worst threats that can be encountered in service.