Boeing 707-121

Photo copyright Clive Dyball - used with permission

Pan American World Airways Flight 214, N709PA

Elkton, Maryland

December 8, 1963

Pan American, N709PA, a Boeing 707-121, operating as Flight 214, departed Baltimore, Maryland, for Philadelphia, Pennsylvania at 8:24 p.m. Eastern Standard Time (EST) on December 8, 1963. The aircraft with 73 passengers and a crew of eight was on an Instrument Flight Rules (IFR) clearance. The airplane reported over the New Castle, Delaware VOR at 8:42 p.m., and was instructed to hold at 5,000 feet, west of the VOR. The airplane was struck by lightning while holding and was immediately observed to be on fire. A large portion of the left wing separated in flight. Flight 214 crashed two miles east of Elkton, Maryland, at 8:59 p.m. The aircraft was destroyed in the crash, and all aboard were killed.

History of Flight

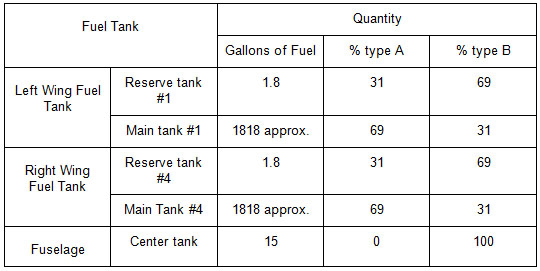

On the morning of December 8, 1963, N709PA departed Philadelphia, Pennsylvania for San Juan, Puerto Rico. The aircraft arrived in Puerto Rico with approximately 25,500 pounds of Type A, or Jet A, kerosene turbine engine fuel. Before leaving Puerto Rico, the aircraft was fueled to a total of 78,000 pounds with Type B turbine engine fuel. The fuel load was distributed such that number 1 and 4 main and reserve B707 fuel tanks were 69% Type B, number 2 and 3 main tanks were 63.5% Type B fuel, and the center tank was 100% Type B fuel.

Upon departing San Juan as Pan American Flight 214 for Philadelphia, a scheduled intermediate stop was made in Baltimore. No maintenance discrepancies were reported by the crew at Baltimore. A visual inspection of the aircraft, including examination for fuel leaks, was performed by a Pan American mechanic, while the aircraft was being refueled, and no discrepancies were noted. Fuel in the amount of 27,400 pounds was added in Baltimore according to this table:

Flight 214 departed Baltimore at 8:24 p.m. EST en route to Philadelphia. Upon being transferred to Philadelphia approach control, the crew was advised that Philadelphia was reporting surface wind at 280 degrees at twenty knots with gusts to thirty knots. The crew advised Philadelphia that they would hold until the squall line passed Philadelphia and the winds subsided. They were given instructions to hold west of the New Castle VOR on the 270 degree radial and given an expected approach clearance time of 9:10 p.m. At 8:58, "MAYDAY, MAYDAY, MAYDAY" was heard on the Philadelphia Approach Control frequency. This is an internationally recognized distress signal indicating imminent and grave danger, and that immediate assistance is requested. Seconds later another transmission on the same frequency was heard stating, "Clipper 214 is going down in flames." This latter transmission was made by the first officer of another airliner in the same holding pattern as Flight 214. The first officer had seen the Pan American flight descending on fire.

The aircraft crashed at 8:59 in open country east of Elkton, Maryland. The aircraft was totally destroyed, and all aboard were killed.

Witnesses in the accident area described the weather as cloudy, with light rain falling, and lightning. Turbulence, thunderstorms, and icing were included in all routine forecasts for the area surrounding the accident site during the period Flight 214 was to be operating in that region. The weather at Wilmington, Delaware, nine nautical miles east of the accident, was reported at 9:00 to be:

900 scattered, measured 4,400 overcast, visibility eight miles, thunderstorm, light rain, temperature 44, dew point 43, wind west-southwest 10 knots, thunderstorm began at 8:54, thunderstorm west, movement unknown, lightning in cloud, cloud to ground west-northwest-northwest.

The Civil Aeronautics Board determined that the probable cause of the accident was lightning-induced ignition of the fuel/air mixture in the number 1 reserve fuel tank, with resultant explosive disintegration of the left outer wing and loss of control.

Photo copyright Michael Bath - used with permission

Atmospheric Lightning

Lightning originates with the concentration of electrical charges in the air or, more commonly, clouds. The most common producer of lightning is a cumulonimbus cloud. Lightning, however, can also occur during sandstorms and in clouds over erupting volcanoes. Lightning has even been reported in clear air, though this phenomenon is rare, and is possibly a result of lightning originating in conventional clouds beyond the observer's field of vision.

The most common types of lightning are those involving a cloud and the ground, called "cloud-to-ground-lightning," and lightning between charge centers within a cloud, called "intra-cloud lightning." True cloud-to-cloud lightning between isolated cloud centers is possible; however, what appears to be cloud-to-cloud lightning is often a manifestation of intra-cloud charges.

Photo copyright Michael Bath - used with permission

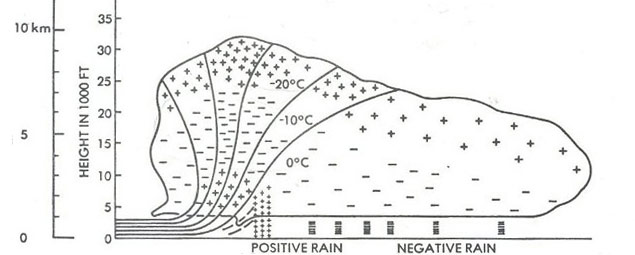

The energy that produces lightning is a result of warm air rising upwards into a developing cloud. As the air rises it becomes cooler, and as it reaches its dew point, the excess water vapor condenses into droplets, forming a cloud. When air has risen high enough for the temperature to drop to significantly subfreezing levels (e.g., -40 degrees Celsius), the water vapor freezes to ice. At lower elevations, there will be many super-cooled water drops that are not frozen, even though the temperature is lower than the freezing point. In this supercooled region, ice crystals and hailstones form.

The cloud becomes electrically charged as ice crystals coalesce into hailstones. These hailstones fall through the cloud, gathering additional supercooled water droplets. As droplets freeze onto a hailstone, small splinters of ice chip off. These splinters carry away a positive electrical charge, leaving the hailstone with a net negative charge. Vertical wind currents in the cloud carry the ice splinters into the upper part of the cloud. Conversely, hailstones fall until reaching warmer air, where some portion of them melts and the remainder continues to earth. As a result, the upper part of the cloud takes on a positive charge, and the lower region takes on a negative charge. The earth beneath the cloud acquires a charge of opposite polarity. Electric fields exist between these charges of opposite polarity.

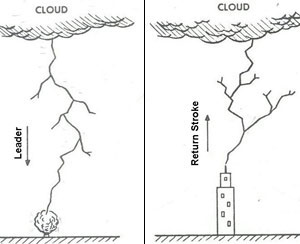

When the electric field between the cloud and the earth becomes sufficiently intense, a discharge towards the earth can take place, beginning as a slow-moving column of ionized air called the pilot streamer. After the pilot streamer has moved a short distance, a more intense spark called a step-leader takes place. As the negatively charged stepped leader approaches the ground, positive charge accumulates on the ground. Electrical field strength on the ground becomes sufficiently large that a streamer starts at the ground and approaches the downward moving leader. When the two streamers meet, electrical charge from the stepped leader can flow easily to the ground. This discharge of the stepped leader is commonly called the "return stroke," and is associated with the flash, and loud thunderclap observed during thunderstorms. The stroke currents can sometimes exceed 200,000 Amperes.

Lightning Effects on Aircraft

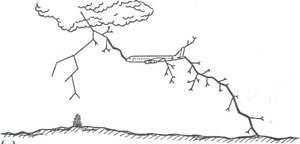

Review of several decades of transport airplane lightning strike data shows that, on average, each airplane is struck once or twice a year. Although the process by which the airplane becomes involved in the lightning channel is complex, it is clear that the presence of the airplane passing through air in the vicinity of a building lightning leader can actually "trigger" the lightning strike event. As a leader propagates from a thunderstorm, streamers may form and move from the airplane towards the developing lightning leaders, much the same as charge propagation from cloud to ground. Initial lightning attachment points are typically at the extremities of the airplane - wingtips, nose, and tail surfaces. Each strike involves both an "attachment" and "exit" point. Since the aircraft is an excellent electrical conductor, the airplane becomes an efficient path for electrical discharge. As the airplane flies through the lightning channel, the channel may re-attach to other surfaces, especially along the fuselage, and across wing and empennage tips. Click the following link to view video of a lab test using a model airplane that illustrates zonal attachment points of lightning.

When the airplane becomes part of the lightning path, current flows through the airplane between various lightning entry and exit locations. These lightning currents travel both on the surface of the airplane and through the airplane's internal structure. A short video shows an actual airplane being hit by lightning and becoming part of the current path to ground.

Effects of lightning strikes on an aircraft can generally be categorized into three main areas. These are:

- Physical damage;

This results from the localized high current and heating associated with the lightning arc event. This may include overpressure within non-conductive enclosures, such as radomes, that have been punctured, pitting or melting of fasteners, and melting through of metal skin surfaces.

- Indirect effects due to the lightning current;

This involves systems or circuits that may lie within airplane structure that is conducting high currents from a lightning strike. These circuits can be electrically impacted by electromagnetic fields that penetrate through aircraft windows and non-conductive surfaces. A system that is found to be vulnerable to the effects of a lightning strike is of particular concern to safety of flight. Since transport airplane safety is largely dependent upon isolated and redundant system architecture, a single-system vulnerability can represent a common cause threat condition, and result in multiple system failure from a single lightning event.

Photo copyright Laurent Cluzel - used with permission

- Ignition of fuel tank vapors;

Lightning-induced arcs or sparks have been found to exist within some fuel tank vapor spaces (expansion space) and have caused vapor ignition and tank explosion to occur. This was determined to have been the cause of the Pan Am Flight 214 accident, though the location of this arc or spark within those fuel tanks was not found.

An additional lightning effect, though rare, will occasionally manifest itself as an engine failure. During the short time interval following a lightning event, the airplane may pass through the column of hot ionized air that is the lightning channel. This column may be close to a vacuum in terms of its oxygen content, and when this stream of gas is ingested by a turbine engine, the burner is immediately deprived of oxygen. This interruption of the inlet air in the engine results in a flameout of the affected engine. The engine is usually not damaged and is able to be restarted, but the momentary loss of oxygen in the burner prevents further combustion until the gas column dissipates.

Accident Investigation

Examination of the wreckage of Flight 214 showed multiple lightning-strike marks to the left wing tip. There was an area of extensive damage on the top surface of the tip along the end rib, in and adjacent to the joint where the wing tip cap and top wing skin were attached to the end rib. The damaged area extended from the trailing edge of the wing to a point about three feet eight inches from the leading edge, measured along the end rib. Within this area there were numerous spots where the metal surface and rivet heads showed indications of melting. The largest single indication of lightning damage was an irregular-shaped hole about 1.5 inches in diameter. There was evidence of high heat in this area, and fused metal was found around the hole.

View Larger

Following are actual pictures of the accident airplane wing tip showing some lightning damage. (Annotated wreckage photographs) The large dark area in the linked photographs was the result of melting of the aluminum skin, exposing the rib beneath. Investigators determined that lightning had attached to fasteners along the wing tip rib, causing melting. In this case the fastener and surrounding skin were melted away by the hot lightning arc. The melted area of the wing was adjacent and outboard of the left wing surge tank. This physical evidence indicates that lightning current entered the wing at this location. An arc or spark must have occurred somewhere within one or more of the wing fuel tanks.

By examining the wreckage, it was determined by investigators that explosions occurred in the left reserve, center, and right reserve tanks, and that no fire-damaged parts separated from the aircraft prior to the explosion. The source of the fuel vapor ignition was not found. No evidence of lightning attachment to the fuel vent outlet or access panels on the wing was found.

View Larger

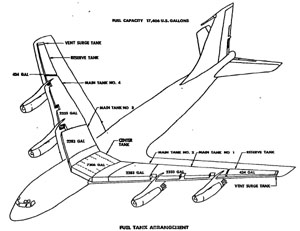

Boeing 707 Fuel Tank System

The Boeing 707 fuel system consists of two main reserve tanks, four main tanks, one center tank, and two surge tanks. Total capacity is 17,406 gallons. The four main tanks and two reserve tanks are completely integral with the wing structure. All fuel tanks are structurally sealed to be fluid tight. Close metal-to-metal fitting of all parts forms the basic seal, and sealing compound is used on all joints and fasteners that are not self-sealing. A number of access doors on the lower wing surface provide access to each fuel tank for inspection and component repair.

In order to equalize pressure between the external atmosphere and the fuel tanks, the 707 airplane, as in most large transport airplanes, incorporates a vent system that provides positive venting of the fuel tanks to accommodate the pressure differentials associated with altitude changes. The vent system is interconnected and vented into a vent surge tank, and overboard through a vent scoop at the wingtip. Float valves are mounted on the vent ducts to prevent fuel from entering the vent system.

View Larger

The five-gallon vent surge tank is located outboard of each wing reserve tank to accommodate overflow fuel vented from the vent ducts during rapid airplane altitude changes. If the surge tank is overfilled, the fuel will vent overboard through the surge tank vent duct. Fuel trapped in the surge tank will flow back into the reserve tank through a check valve. The check valve prevents fuel in the reserve tank from entering the surge tank.

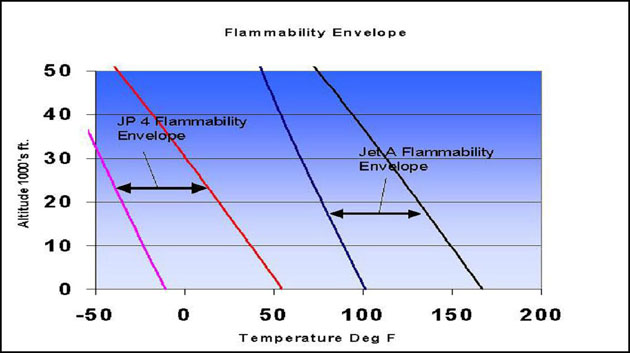

Fuel Tank Flammability

The engines on the 707 are qualified to burn both Type A and Type B jet fuel. Type A fuel is a kerosene-type turbine fuel with a flammability envelope ranging from approximately 110 - 150 degrees F at sea level pressures. Type B fuel is a "wide-cut" aviation gasoline-type turbine fuel, and has a flammability envelope encompassing a cooler temperature range than Jet A. In order for an explosion to occur in a fuel tank vapor space, the fuel vapor must be flammable, and there must be an ignition source present. The ignition source in this accident was thought to be from the lightning strike to the aircraft. While lightning can cause damage to aircraft structure, the catastrophic loss of the aircraft from a fuel tank explosion only results if the fuel mixture is flammable and there is an ignition source within the fuel vapor space.

View Larger

For the flammability envelopes associated with each fuel type, the left boundary of each envelope represents the "lean limit," and the right boundary represents the "rich limit." At the lean limit, the fuel-air mixture contains too little fuel to be flammable. At the rich limit, too much fuel is present, and ignition is not possible. As a result of the accident airplane having been fueled with a blend of Type A and B fuels while in Puerto Rico, the flammability limits extended to the extremes of both fuel types. The blended fuel effectively retained the lean limit of the Type B fuel and the rich limit of Type A fuel. The resulting flammability envelope was therefore much larger than either individual envelope, and yielded a fuel that was flammable through a wider range of conditions than either of the component fuels.

Photo copyright Michael Bath - used with permission

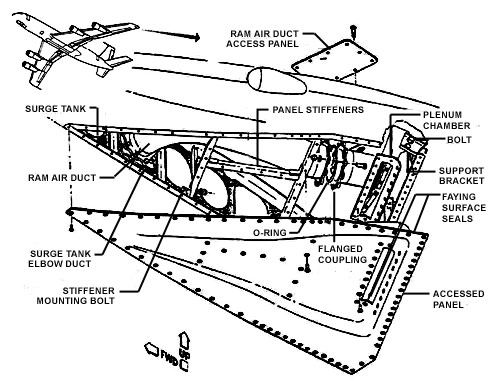

Airplane Lightning Protection

Lightning can interact with the airplane in several ways. High currents associated with direct lightning strikes to wings flow through the airplane skins and substructures. This high current flow is accompanied by strong magnetic fields that surround the airplane. Some of these fields may penetrate to the interior of the airplane through windows and other apertures and may induce transient voltages in electrical wiring. Lightning currents in airplane skins may produce electric arcs at discontinuities, such as wing tank access panels, which may appear inside the wing tanks. In order to minimize this effect, access panels, filler caps, and drain valves are electrically bonded to surrounding structure. This ensures that the lightning currents are conducted across these removable parts without producing arcs.

Lightning striking the airplane skin can also diffuse through the skin material and result in voltages or currents on internal conductors. Aluminum skins keep most of the lightning currents in the skins, but some currents can also reach internal structural elements and system conductors, such as cables and pipes. Finally, a direct attachment of a lightning stroke to the exterior surface of a wing fuel tank can melt through the skin. Skin thicknesses are designed to ensure that a lightning strike does not cause complete melt-through of the skins of integral fuel tanks. There was no evidence that lightning melted a hole into one of the Elkton B707 wing tanks.

Photo copyright Nils Rosenberg - used with permission

The magnitudes of these currents are considered in designing the various electrical and mechanical bonding features between aircraft parts which become part of the lightning current paths. If parts are not properly bonded then lightning currents can cause arcing between structural elements. If this arcing occurs within a fuel tank where the fuel vapor is flammable, then a fuel vapor ignition or explosion may occur.

The flow of charge to the airplane can cause local heating which can melt the wing skin and expose flammable fuel vapor to lightning arcs whose temperature is near 30,000 degrees Celsius. These high temperatures can act as an ignition source to ignite a flammable fuel mixture. Therefore, the skin of the airplane has to be of sufficient thickness that it does not melt completely through while the lightning channel is attached to a spot on the skin.

Airplane systems, such as flight controls, engine controls, avionics, etc., are designed with complex architecture, and contain many redundant features to make them fault or failure tolerant. In order for this redundancy to be maintained in an environmental event such as lightning (which can affect multiple systems), it is important that each individual system be "hardened" against a conservative lightning threat. For example, system isolation/segregation provisions require that engine electronic control functions be unaffected by a lightning strike event, ensuring that the failure of multiple engines does not result from a lightning environment.

Photo copyright Wolodymir Nelowkin - used with permission

Conclusions

At the time of the development of the Boeing 707, much less was known about the behavior of lightning relative to airplanes and airplane systems than is known today. Only rudimentary lightning protection standards were in effect. The conclusion of the Elkton B707 crash investigation was that the Boeing 707 embodied the safety features that were available at that time. It was recommended that further research into lightning effects on aircraft was necessary to prevent lightning-related accidents from occurring in the future. This accident became one of the catalysts for this lighting research, and eventually led to the development of regulations, lightning environment and test standards, protection design guidance material, and improved safety protection strategies for all commercial aircraft.

The accident report was published prior to a time that accident investigation boards addressed specific findings. However, based on a review of the report, a summary of the findings can be made:

- The board determined that the probable cause of this accident was lightning-induced ignition of the fuel/air mixture in the number 1 reserve fuel tank with resultant explosive disintegration of the left outer wing and loss of control.

- Multiple lightning-strike marks were found on the left wing tip. The damaged area extended from the trailing edge of the wing to a point three feet eight inches from the leading edge. Numerous spots where the metal surface and rivet heads showed indications of melting.

- A hole about 1.5 inches in diameter was found at the trailing edge of the wing tip with evidence of high heat and fused metal found around the hole.

- Electrical resistance measurements on fuel tank access plates varied from no resistance to 250K ohms. Highest readings were obtained where bonds had been broken.

- Actual mechanics of ignition of the left reserve tank contents was not determined.

- Many questions remain regarding the upper limits of voltage, current, and total energy that may be associated with lightning.

- The lightning protection requirements of the FAA were satisfied by Boeing.

- Fuel vapors in all tanks were flammable.

- The accident review board noted a Coordinated Research Council conclusion regarding the relative safety of Type A and Type B fuel (similar to JP-4) that a single type of aviation turbine fuel by the industry would not significantly improve the safety record of commercial aviation overall.

- Research outside the boards investigations showed that direct lightning strikes to over-wing filler caps and access plates of the configuration used on the accident aircraft can produce sparks inside the fuel tank. No evidence of direct strike was found on these parts in the accident airplane.

For a complete review of the findings of this investigation see the Civil Aeronautics Board, Aircraft Accident Report, Pan American World Airways Boeing 707-121, N709PA, Near Elkton, Maryland, December 8, 1963.

The Civil Aeronautics Board issued a number of recommendations relative to various aspects of lightning protection. The complete text of these recommendations has been compiled here: (CAB recommendations).

Currently Code of Federal Register (CFR) paragraphs 25.581, 25.954, and 25.981 are applicable regulations which address lightning protection and fuel tank safety. These regulations were not in existence at the time of the Flight 214 accident. The Boeing 707 was designed to meet the standards contained in Civil Air Regulations (CAR), part 4b - Airplane Airworthiness Transport Category as amended to December 31, 1953. These regulations do not contain any lightning design requirements. Section 4b.421 addresses fuel tank tests, but there is no mention of any lightning requirements in this section.

The Civil Aeronautical Board, the investigating agency, stated, "Based on evidence furnished [to] the Board, it is reasonable to conclude that the state of the art was fully exploited within the limits imposed by basic airplane structural and configuration requirements in the design of the fuel system, including the vent outlets. Application of known lightning protection information as well as specific testing was applied during the design stages. The lightning protection requirements of the Federal Aviation Agency were satisfied."

A large body of knowledge of lightning characteristics was available at the time of the Flight 214 accident, and a Lockheed Constellation accident in Milan, Italy, but this knowledge resided in the electric power industry, and only a small portion of this knowledge had become known by the aircraft manufacturers and airworthiness authorities. The prevailing thinking was that since aluminum was a very good electrical conductor, and lightning currents were of short duration they would remain in the airplane skins, and components enclosed within were not expected to carry currents. It was thus ‘hard to believe' that lightning could do much damage to an airplane. A notable exception to this was the work of the National Advisory Committee for Aeronautics (NACA) Subcommittee on Lightning Hazards to Aircraft, formed in or about 1934. That committee was disbanded around 1948. Much of the work centered on how to avoid lightning strikes, protecting the exterior skins, and protection of radios and radio operators who often wore headphones. Little of this work centered on the protection of fuel tanks from lightning.

The Milan and Flight 214 accidents happened in the days of vacuum tube electronics that tolerated lightning-induced transients very well, so there was little concern for lightning-indirect effects coupling mechanisms into aircraft wiring that would have focused more attention on what else happens inside airplane skins and within fuel tanks.

The fact that lightning was the apparent cause of some of the in-flight fuel tank explosions was sometimes disputed by the aircraft manufacturers (severe turbulence was sometimes proposed as the cause).

There were considerable reservations related to the discussion of the possible role of lightning on the damage and loss of civil airplanes, perhaps related to a perception that the public was best served by keeping the related accident investigations and research information in the hands of lightning specialists. This is evidenced by frequent confidentiality warnings in many of the NACA papers.

- Inadequate protection of fuel tank access doors and fuel vent outlets from lightning

- Inadequate wing skin thickness at the fuel surge tanks

- Inadequate information regarding the lightning environmental threat

- Flammable fuel mixture in the presence of inadequate lightning protection

It was assumed that lightning currents flowed exclusively on airplane aluminum skins so that components enclosed by these skins were inherently safe.

Prior to this accident, airplane lightning protection emphasized prevention of fuel tank skin puncture and skin heating at the lightning attachment point. This was consistent with the damage observed on non-fuel tank structure (ref NACA Tech Note 4326, 1958). The studies and requirements did not address potential ignition sources due to high lightning current conducted on individual fasteners, nor did they address lightning ignition sources in fuel and vent tubes and couplers. Studies on potential fuel tank vent fires had been reported at the time of the accident (ref INVESTIGATION OF MECHANISMS OF POTENTIAL AIR CRAFT FUEL TANK VENT FIRES AND EXPLOSIONS CAUSED BY ATMOSPHERIC ELECTRICITY, M. Gerstein, May 1963), but design and certification requirements predated these findings.

The in-flight fuel tank explosion accident investigation of a Lockheed Super-Constellation operated by TWA near Milan Italy on June 26, 1959, prompted research into protection of fuel vent systems and filler caps. But, since the source of

Photo copyright Bob Gerrard - used with permission

ignition in that accident, like the Flight 214 accident, was never found, research activities did not extend into other aspects of fuel system design. Researchers remained fixated on the possibilities of vent vapor ignition and propagation of flames throughout vent systems (propagation from tank to tank within the Flight 214 B707 apparently did occur). Accidents involving fuel tank explosions from lightning continued to occur.

Post-Accident Improvements in Lightning Protection Standards

The Flight 214 accident, together with the crash of a TWA Constellation near Milan, Italy in 1959, and fuel tank explosions in several military transport airplanes during the same time period, resulted in an accelerating of the development of improved lightning environment, test, regulatory, and design standards for design and verification of lightning protection for airplanes. In the Flight 214 accident report, it was noted that "although much has been learned about lightning and its effects through research and study, many questions are still unanswered and the upper limits of voltage, current and total energy that may be associated with lightning are not conclusively defined."

As a result of the accident, the FAA formed a technical committee on lightning protection for aircraft fuel systems, composed of representatives from the FAA, Civil Aeronautics Board, and various other government agencies as well as industry lightning experts. In January 1964, less than one month after the Flight 214 accident, the FAA outlined in a memo the proposed scope of the research effort. A copy of this letter is available at the following link: (Letter Forming Lightning Protection Committee)

The minutes of the first meeting provide considerable insight into the thinking of the lightning community at the time of the accident. The Flight 214 accident was reviewed, as well as what was known of the possibility that lightning was the cause. There were discussions of electrostatic discharge, bonding, and fuel flammability. A link to the minutes of this first meeting is available at the following link: (Minutes of First Committee Meeting)

Cited in this first meeting was earlier work done by the Lightning & Transients Research Institute (LTRI). In September 1958, LTRI published a technical note regarding the hazards to aircraft fuel tanks from lightning. This work, although predating the Flight 214 accident, formed the basis for later FAA Advisory material on the protection of fuel systems against fuel vapor ignition caused by lightning. This report is available at the following link: (LTRI report - Lightning Hazards Research September 1958)

Specific fuel system lightning protection regulations were adopted for transport category airplanes, in § 25.954 [Amendment 25-14 August 11, 1967]. In addition to this amendment, guidance for fuel system lightning protection was published in Advisory circular 20-53, which has been subsequently revised as Advisory Circular 20-53B. Though Advisory Circulars 20-53 and 20-53A were superseded by 20-53B, the FAA also published a "User's Manual for AC-20-53A" that continues to be referenced in the current version of the AC.

To support these regulatory and guidance changes, significant research was performed immediately following the accident and over the next decade. The immediate research considered the interaction of lightning with the fuel tank vent systems [ref Airflow Velocity Effects on Lightning Ignition of Aircraft Fuel Vent Efflux, July 1967]. There was additional work to define the lightning characteristics appropriate for aircraft lightning protection design and test [e.g., ref N. Cianos & E. T. Pierce, A Ground-Lightning Environment For Engineering Usage,. Stanford Research Institute, August 1972], as well as research to define the minimum fuel tank skin thickness required to prevent fuel ignition [e.g., ref A STUDY OF AIRCRAFT FIRE HAZARDS RELATED TO NATURAL ELECTRICAL PHENOMENA, F.L. Kester, M. Gerstein, J. A. Plumer, June 1968]. The results of research and development related to aircraft lightning protection were presented at regularly scheduled conferences on lightning and static electricity. An industry committee was chartered [SAE AE4L Lightning committee, which became SAE AE2 Lightning committee] to develop aircraft lightning protection recommended practices, lightning protection verification test methods, and standard definitions for lightning characteristics.

The requirement to protect the airplane from the catastrophic effects of lightning was introduced in 25.581 at amendment 25-23, May 8, 1970.

As a result of the TWA Flight 800 accident in 1996, the airplane fuel tank ignition rule was created. 25.981 was introduced as amendment 25-102 dated June 6, 2001. This regulation specifically required that ignition sources, including those from lightning, within the fuel tank be addressed.

In 2006, the FAA issued AC 20-155 "SAE Documents to Support Aircraft Lightning Protection Certification" to provide guidance as to relevant means of compliance with regulatory criteria. This document was subsequently updated, and the updates are included here: (AC 20-155 Update)

Test Standards

Research from LTRI, the Federal Aviation Agency (prior name of the FAA), Lightning Protection Committee, and others ultimately resulted in new and improved lightning protection means for aircraft.

Before better lightning protection could be incorporated into aircraft design, a characterization of the lightning environment had to be made. Ultimately, lightning environment definitions and test standards were developed so that aircraft structure and interaction with the lighting environment could be quantitatively assessed. Lightning does not strike all areas of the aircraft with the same frequency. Also, various areas of the airplane experience different lightning characteristics. This led to the concept of aircraft lightning strike zones which are exposed to different components of a lightning current test waveform.

Using this approach to lighting protection and defining the test environment with aircraft zoning, actual lightning testing is done in the laboratory to confirm that the airplane structure is adequately protected from a lightning attachment event. Test panels are exposed to a test lightning waveform. A video of an example of this testing is available below:

Airplane Design Improvements

Electrical Bonding

As a result of Airworthiness Directive action and research and development into new lightning test standards and regulations, many improvements to the lightning protection of aircraft have resulted.

There was an increased emphasis on electrical bonding of components installed in the wing tank skins to surrounding skins and structures. Examples are access panels, fuel filler caps, drain valves, and dip sticks (devices used to measure fuel quantity). There was not, however, a commensurate degree of concern about the effects of lightning currents flowing on internal structural elements and system components. Subsequent to Flight 214, the prevailing opinion among specialists was that lightning currents flowed in aluminum skins. It was not until a 747 accident in 1976, near Madrid, Spain, and some military accidents, that lightning-protection specialists began to think equally about the effects of lightning currents inside fuel tanks as well as in the exterior surfaces.

Fuel Vent Flame Arrestors

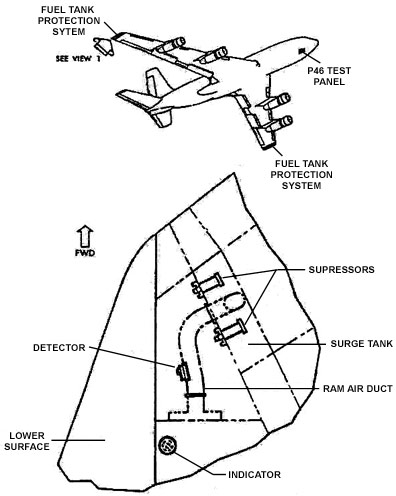

As a direct result of Airworthiness Directive action, improvements to the fuel surge tank lightning protection have been made to protect against lightning currents entering the fuel tanks through the venting system. Many airplanes incorporate an explosion-suppression system to extinguish flames ignited at fuel vent outlets or in the fuel surge tanks. One such system was designed for the Boeing 707.

In the Boeing 707 system, a photoelectron cell is used to monitor the inside of the overboard vent duct between the vent surge tank and the vent scoop. When a flame radiation is sensed in the overboard vent duct, the two suppressors are actuated, discharging a suppressant into the surge tank area. The suppressant will render the surge tank inert until the danger of explosion has passed.

Vent Flame Arrestors

These are passive devices that are inserted in vent pipes to cool (quench) flames that are ignited at the vent outlets.

Wing Skin Panel Thickness

Lightning attachment can cause high localized heating of the wing skin where the attachment occurs, causing the wing skin to melt and allowing the very high temperature lightning arc to come in contact with fuel vapors, which could lead to an explosion of these vapors. Thus, the airplane skins over the fuel tanks must be designed to adequately protect from effects of lightning attachments. The Boeing 707 accident airplane had a minimum wing skin thickness in the area of attachment of .064 inches. Based on updated definition of the lightning threat, airplane aluminum skins are defined to have a minimum thickness of about .080 inches to protect from melt-through where lightning attaches to the skins.

- AD 64-05-01, effective December 12, 1964, required modification to install additional aluminum skin over the entire vent surge tank area of the wing.

- AD 64-03-01, effective June 30, 1965, required modification of wing tank access panels to address possible internal sparking due to lightning.

- AD 67-23-02, effective September 10, 1967, required installation of either a flame and explosion suppression system in the fuel tank vent outlet system, or an additional vent tube with flame arrester to the vent system surge tank.

Airplane Life Cycle:

- Design / Manufacturing

Accident Threat Categories:

- Fuel Tank Ignition

- Inclement Weather / Icing

Groupings:

- N/A

Accident Common Themes:

- Flawed Assumptions

Flawed Assumptions

The assumption at the time of Boeing 707 development was that proper electrical bonding of fuel system components would provide inherent protection against a lightning-induced fuel tank explosion. Research since this accident has revealed that, in addition to adherence to sound electrical bonding criteria, additional means have been shown to be necessary. These include electrical shielding, increased skin thicknesses to prevent lightning penetration, and a better understanding of lightning strike zones on an aircraft. All have resulted in a mitigation of the lightning threat and better lightning protection systems in the modern jet fleet.

Lockheed Constellation near Milan, Italy, June 6, 1959

Lansa, Flight 508, Lockheed L188 near Pucallpa Peru, December 24, 1971.

Iranian Air Force B747-100 (formerly owned by TWA) near Madrid, Spain, May 9, 1976

Technical Related Lessons

An aircraft's fuel system must be protected against the effects of a lightning strike. (Threat Category: Fuel Tank Ignition)

- Although the precise origin of the fuel tank ignition in this accident was not identified, the investigators believed that fuel vapor was ignited, resulting in a catastrophic overpressure of the tank, beginning in the left-wing reserve tank. Examination of wreckage revealed that complete penetration had occurred at some locations on the wing skins. Research conducted following this accident revealed that aluminum skin thicknesses were required to be at least .080 inches in order to prevent penetration by a lightning strike. Areas of the Boeing 707 fuel tanks with skin thicknesses less than this value were required to be changed subsequent to this accident.

Common Theme Related Lessons

Compliance with electrical bonding requirements alone will not provide adequate protection against the effects of a lightning strike. (Common Theme: Flawed Assumptions)

- At the time of the Boeing 707 development, it was assumed that electrical bonding provided inherent protections against lightning strikes. While the fuel flammability envelopes were well understood, it was assumed that as long as the electrical bonding requirements of the fuel system components were satisfied, a lightning strike would not result in an in-tank arc and fuel tank explosion. Testing conducted following this accident yielded much greater understanding of the indirect effects of lightning (i.e., induced voltage levels), as well as direct effects (i.e., skin penetration).