Boeing 757-200

Photo copyright - used with permission

Birgenair Flight ALW 301, TC-GEN

Puerto Plata, Dominican Republic

February 6, 1996

At 0342, Birgenair flight ALW-301, a charter flight for Airline Alas Nacionales, a Boeing Model 757-200, took off from Gregario Luperon International Airport, Puerto Plata, Dominican Republic, with a final destination of Frankfurt, Germany. During the takeoff roll the captain noticed his airspeed indicator was not properly displaying airspeed. He continued the takeoff using speed calls from the first officer, whose airspeed indicator seemed to be functioning properly. After becoming airborne the captain's airspeed indicator seemed to begin functioning, and indicating an increasing airspeed. During climb-out, after engaging the autopilot and autothrottle, the crew realized that airspeed indications were abnormal. The airplane had reached an unusually high attitude, yet speed indications were increasing, resulting in an overspeed warning. Believing the aural warning to be in error, the crew deactivated the overspeed warning system. Though the indicated airspeed remained high, the stall warning "stick shaker" activated, and the autothrottle and Vertical Navigation (VNAV) mode disengaged.

Investigators determined that the crew was confused by the combination of airplane pitch, indicated airspeed, and conflicting warnings. Flight recorder data indicated a number of thrust and pitch excursions prior to the disconnection of the autopilot. Following a number of pitch and thrust changes, airplane control was lost, and approximately 5 minutes after takeoff, the aircraft impacted the water in a severe nose-down attitude, approximately 14 nm northeast of Puerto Plata. All 13 crew and 176 passengers were killed.

The Board determined the probable cause to be the failure of the crew to recognize the activation of the stick-shaker as an imminent warning of entrance to aerodynamic stall and their failure to execute proper procedures for recovery from the loss of control. They also cited a cause as confusion by the flight crew due to the erroneous indication of increasing airspeed and associated overspeed warning.

History of Flight

Birgenair flight ALW-301 was a Boeing Model 757-200 that was being operated as a charter flight for Alas Nacionales Airlines. The flight was originally scheduled to be flown with a Boeing Model 767. Maintenance problems on the original 767 prevented its use, so approximately 2 ½ hours prior to the flight a 757 was substituted, and a new crew was assigned.

During the takeoff roll, the captain's airspeed indicator appeared to have failed. However, the captain, who was the pilot flying, ordered the first officer to call out reference airspeeds based on his own indicator, and the takeoff was continued, Once airborne, the captain's airspeed indicator appeared to begin functioning. The autopilot and autothrottle systems were engaged, and the airplane appeared to enter a normal climb. Within seconds of engaging the autopilot, both the captain and first officer recognized that a problem was occurring. The first officer commented that his airspeed was indicating 200 knots, and decreasing, while the captain's indicator showed an increasing airspeed. At this point, altitude was 5344 feet, and the captain's airspeed indicator read 327 knots. Pitch attitude was 15.1 degrees. The captain commented that both airspeed indicators were in error and asked the first officer, "what do we do," before asking for a check of the circuit breaker panel. The reason for checking the circuit breakers was never established by the investigiation.

One minute after autopilot engagement, at an altitude of 6688 feet, and a captain's indicated airspeed of 352 knots, with a pitch attitude of 15.1 degrees, the overspeed warning sounded, and the captain commented, "this is not important," while ordering that the overspeed warning system circuit breaker be pulled in order to silence the warning. Altitude had reached 7040 feet, and the captain's indicated airspeed had slowed slightly to 349 knots while pitch had reduced to 14.8 degrees.

Twenty four seconds after the occurrence of the overspeed warning, the stick shaker (stall warning) began. The autothrottle and selected autopilot mode (VNAV) disengaged, but the autopilot itself remained connected. At an altitude of 7132 feet, and a captain's indicated airspeed of 323 knots, thrust on both engines was momentarily reduced, then after five seconds was restored to near takeoff thrust. The airplane pitched up to 21 degrees, and the autopilot disconnected. Pitch began to oscillate between 5 and 21 degrees.

Thirty-nine seconds after initiation of stall warning, altitude had decreased to 5984 feet, and captain's airspeed had reduced to 194 knots. Pitch had further reduced to 14.4 degrees, and thrust was again reduced to near idle. After an additional 21 seconds, the captain again commanded a thrust advance in an attempt to arrest the descent. Within a few seconds, thrust on the left engine was reduced to a low level, while thrust on the right engine remained high. Pitch, bank angle, and heading began to oscillate, characteristic of a spin. Asymmetric thrust was maintained, and pitch, altitude, and heading continued to vary until impact with the Atlantic Ocean. All 189 occupants were killed, and the airplane was destroyed on impact.

Investigators determined that, in fact, the captain's pitot tube was blocked, and the captain's airspeed indication was incorrect, becoming more in error as the airplane climbed. Due to the pitot blockage, airspeed appreared to be continuously increasing, which resulted in the autopilot continuously increasing pitch in order to slow the airplane to the selected climb speed. Investigators determined that this pitch increase actually resulted in a slowly increasing angle of attack, and eventually caused the airplane to stall.

Aircraft Maintenance

Just prior to the accident, the accident airplane had been on the ground for maintenance for over 20 days. During this time maintenance personnel conducted an engine inspection which required an engine ground test run before the next flight. Maintenance records reviewed by the investigators did not indicate any airplane discrepancies. However, investigators believed the airspeed system pitot covers had not been installed before, or after, the engine ground test. These covers protect the pitot tubes against the presence of any foreign bodies, or materials entering the pitots. The pitot tubes measure airplane total pressure, and provide information to the air data computer in calculating and indicating airspeed.

Analysis of the cockpit voice recorder (CVR) and the flight data recorder (FDR) indicated that the captain did not have any indication of airspeed until after takeoff. Once airborne, airspeed indications began, but the data presented were inaccurate. Investigators believed the captain did not understand the indications were incorrect. Recorded errors were consistent with indications that would be seen with a blocked captain's pitot tube.

Investigators felt the probable cause of the obstruction was likely to have been mud and/or debris from a small insect that built a nest inside the pitot tube during the 20 days it was on the ground in Puerto Plata. This was not an uncommon occurrence for this area, which is why it was critical to cover the pitot probes whenever the plane was not in service.

The investigation learned that the aircraft was returned to service without perfoming all of the manufacturer's prescribed return-to-flight maintenance tasks. After being on the ground for an extended period (20 days), the manufacturer's maintenance manual recommended a functional check of the pitot-static system. If this check had been completed, the blocked pitot tube would most likely have been discovered and corrected prior to the next flight.

Mud Dauber Wasp

The "Black and Yellow Mud Dauber" wasp is suspected to have been the culprit in the blockage of the captain's pitot tube. This wasp is notorious for quickly filling open holes, such as pitot tubes, with nests. The wasp builds a simple, one-cell nest made of mud, that is attached to crevices, cracks, corners or inside holes, and then lays a single egg. Mud daubers have been implicated in several aircraft accidents and numerous incidents.

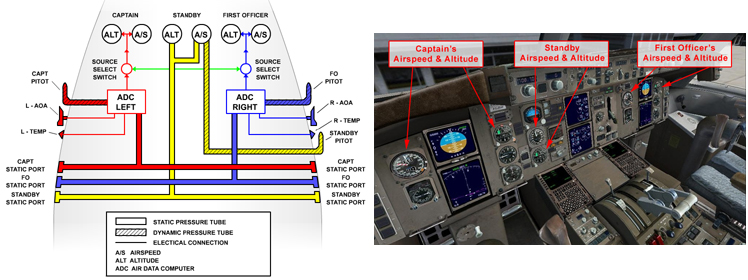

Airspeed and Altitude

Airspeed and altitude are determined by measuring the static and/or dynamic pressures of the air around the aircraft. More sophisticated airplanes also have sensors to measure the air temperature and angle of attack (AOA) which are used to correct the pressure data and enhance airspeed and altitude measurement accuracy.

Static pressure is typically measured by sensing pressure through a port on the fuselage, perpendicular to the local airflow, such that air flows over the port, rather than into the port.

Dynamic pressure is measured by a "pitot tube." A pitot tube is a fixture that extends into the windstream, past the air boundary layer of the aircraft, and measures the free-stream pressure caused by the aircraft's forward movement.

Altitude is derived strictly from static pressure. Static pressure in the atmosphere decreases linearly as a function of increasing altitude. An altimeter transforms sensed static pressure into an altitude via a mathematical equation. Similarly, airspeed is a mathematical function of the difference between the dynamic pressure and the static pressure. A larger pressure differential results in a higher indicated airspeed. On the 757, pitot and static pressures are used by an air data computer to determine airspeed and altitude, which is electronically sent to pilot displays on the flight deck.

757 Pitot Static System

The captain, first officer (FO) and the standby airspeed and altitude displays all have independent sources of dynamic (pitot) and static pressure. These pressures are sent to dual Air Data Computers (ADC), and are corrected for temperature and angle of attack, to present a very accurate airspeed and altitude to the pilot's and first officer's displays. The standby displays utilize only the pitot and static pressures, and are not corrected for temperature or angle of attack. If any indication is suspected of being unreliable, either pilot can push a switch to change his display to use the other pilot's source. Or, either pilot can refer to the center panel standby display.

Crew Procedures

The investigation cited several areas of breakdown in crew operations. The pilot in the left seat (the captain) was the pilot flying, and the first officer (FO) in the right seat was the pilot monitoring. There was also a third pilot, sitting in the flight deck "jump seat" (aft of the center console) acting as a relief pilot due to the expected flight duration. The relief pilot was not acting as a crewmember during the accident sequence, but was technically on duty, and could be called upon in case of emergency.

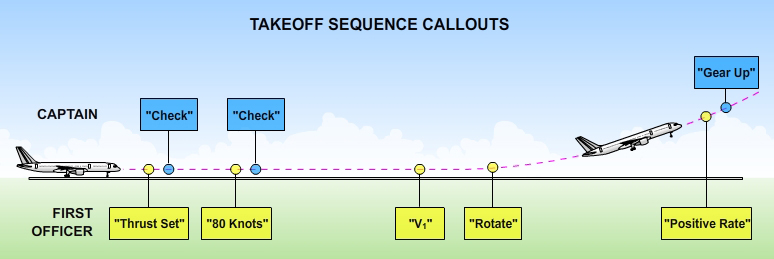

Investigators determined that the crew did not follow standard operating procedures (SOP) during the takeoff roll. There are several key airspeeds that trigger actions during the takeoff sequence:

- The first checkpoint occurs at 80 knots. The pilot monitoring (in this case, the first officer) calls out "80 knots." The pilot flying is supposed to verify that airspeed indicators agree, and usually responds by saying "check." Standard procedure is to abort the takeoff for any warning lights or anything unusual up to that point.

- The second checkpoint is "V1," or "Engine failure speed." The pilot monitoring calls out "Vee-One." This is the highest speed at which an engine failure can occur and the takeoff can be safely rejected and the airplane stopped on the runway. Prior to reaching V1, the crew should reject the takeoff for any safety of flight issue such as engine failure, fire or any control problems. Once past V1, takeoff should be continued, even in the event of an engine failure or other mechanical problems. The only reason to stop after V1 would be an indication that the airplane would be unable to fly.

- The final checkpoint during takeoff ground roll is "VR," or "Rotation Speed." At VR, the pilot monitoring calls out "Vee-R" at which point the pilot flying pulls back on the control column and rotates to the takeoff attitude. Following liftoff, the pilot monitoring sees a positive rate of climb on the altimeter, and calls out, "positive rate." The pilot flying then calls, "gear up," and the pilot monitoring raises the landing gear.

During this accident after the "80 knots" call by the FO, the captain first responded with, "Check," but within 2 seconds stated, "My airspeed indicator's not working." At this point, per standard procedures, the takeoff should have been rejected. Rather than call for a rejected takeoff however, the captain then conferred with the FO for about 7 seconds to confirm that the FO's airspeed was working and remarked, "you tell me," indicating that the FO should call out the remaining takeoff speeds (V1 and VR) using his own indicator.

During climb, static pressure decreases as altitude increases. In this accident, this created an increasing difference in pressure between the sensed static pressure and the constant (sea level) pressure in the plugged pitot tube. This difference resulted in an increasing airspeed indication on the captain's display. Shortly after liftoff, because the airplane had climbed, the captain's airspeed indicator appeared to begin functioning, but was in fact only indicating the increasing pressure difference between the "trapped" pitot pressure and the correctly functioning static pressure source. An airspeed indication was confirmed by the captain, as he remarked, "It began to operate," about 22 seconds after liftoff. Investigators believed that whatever airspeed indication problem had manifested itself on the ground was perceived by the crew to have been resolved.

The captain then engaged the autopilot VNAV mode (which used the captain's airspeed source) to maintain the selected climb speed. In this mode, with the throttles at a fixed climb thrust, the autopilot pitches the aircraft up or down to maintain the selected climb speed. During normal operation, to accelerate the airplane the autopilot commands the airplane to pitch down. If a deceleration is necessary, the autopilot commands the airplane to pitch up. In this case, with the speed appearing to continuously increase as the airplane climbed, the autopilot continued to command increasing pitch in order to slow the airplane to the commanded climb speed.

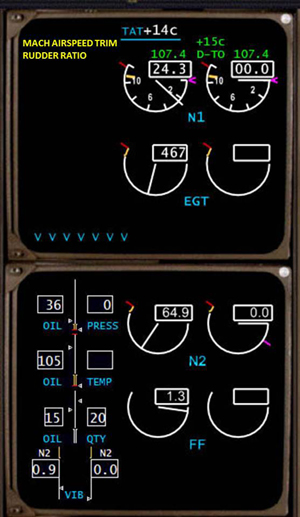

(Engine Indication and Crew Alerting System) Information

Activation of an aural alarm and illumination of a master caution light alerted the crew to EICAS (Engine Indication and Crew Alerting System) messages. In the center of the instrument panel are two vertically placed electronic displays that show EICAS information. Caution and advisory messages appear on the left hand side of the upper display. Both a "RUDDER RATIO" and "MACH AIRSPEED TRIM" message appeared, and were the first indication that an airplane anomaly existed. Both crew members remarked, "..something's crazy," and attempted to diagnose the problem. The FO stated, "...right now mine is only 200 and decreasing sir" (referring to his airspeed indicator). This statement is an accurate reflection that the autopilot is pitching the nose up in response to the increasing indicated airspeed on the Captain's display. This was the point at which the captain stated, "Both of them are wrong, what can we do?"

The captain then requested that the FO to check the circuit breakers, though it was not clear to the investigation which circuit breakers he intended to be checked. Both the captain and FO agreed that the alternate (standby) system was correct, however, it appeared to the investigation that they did not revert to use of the standby airspeed indicator, or compare all three indicators. Investigators believed that only the captain's display was incorrect, and if control of the airplane had been transferred to the FO, or if the captain had begun using the standby indicator as his primary airspeed reference, the accident might have been averted.

At this point, faced with conflicting warnings - an overspeed warning generated from the captain's airspeed system, and a stall warning based on an excessive angle of attack, investigators believed the crew became confused. Both crew members were apparently aware that an airspeed indication problem of some kind existed, but they were unable to correctly diagnose the problem, and seemed to investigators to be unaware that the stall warning system functions completely independently from the airspeed system. Lack of a proper response to the stall warning was cited by the investigation as the probable cause of the accident.

At the time of the accident, there were no identifiable EICAS messages or applicable procedures related to unreliable airspeed. Eight months prior to the accident (June of 1995), Birgenair had added a paragraph to their Flight Crew Training Manual regarding "Flight with Unreliable Airspeed," however, the investigation could not determine if the crew had been briefed or trained on this change. Even if they had, it appears they did not follow the advice. Following the accident, Birgenair added an "Airspeed Unreliable" procedure to their pilot checklist.

The German Federal Bureau of Aircraft Accidents Investigation (German: Bundesstelle für Flugunfalluntersuchung, BFU) produced an animation of the accident sequence. Versions in both German (the original version), and English (a translation) are available at the following links:

- Birgenair Flight Path Animation (German):

- Birgenair Flight Path Animation (English):

Conclusion

Investigators determined that the probable cause of the accident was the flight crew's improper response to the stall warning, and confusion on the part of the flight crew resulting from the airspeed indication anomaly. The investigation discussed the lack of flight crew response while the airplane was still on the ground during takeoff roll, when the captain recognized that his airspeed indicator was not functioning, but did not list it as a contributing factor.

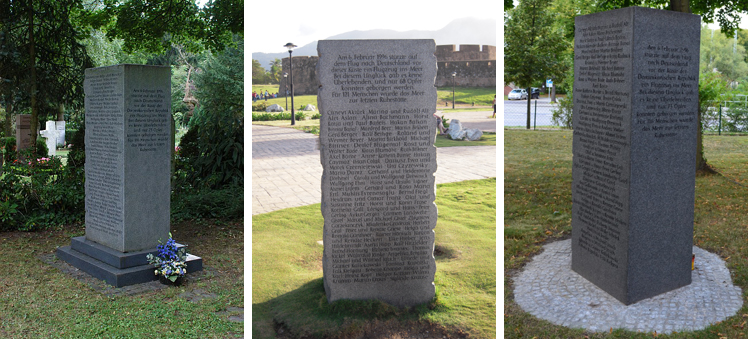

Accident Memorials

Three memorials were erected to commemorate the accident. All three are similar obelisks carved from the same piece of granite. The monument on the left was placed in the main cemetery in Frankfurt, Germany, the city where the flight was to terminate. The middle photo is the monument placed in San Felipe, on the seafront of Puerto Plata, to mark the crash site. The photo on the right is the monument placed in the town church of Schonefeld, Germany, near the Berlin airport where the flight was to have made an intermediate stop.

The Dominican Republic Air Accidents Investigation Board (JIAA) concluded that the probable cause of the accident was the failure on the part of the flight crew to recognize the activation of the stick-shaker as an imminent warning of an entrance to aerodynamic stall and their failure to execute proper procedures for recovery of the control loss. Before activation of the stick-shaker, confusion of the flight crew occurred due to the erroneous indication of an increase in airspeed and a subsequent overspeed warning.

The following were also cited as contributors:

- Flight crew training, actions taken in the cockpit, use of proper procedures and basic aeronautical abilities.

- Lack of knowledge of the aircraft on the part of the flight crew: including aircraft systems, airspeed indications, automatic pilot, aircraft procedures, selection of alternate sources of data and flight with an untrustworthy airspeed indicator.

- Maintenance practices - not installing the pitot system covers while the aircraft was on the ground, the failure ot perform tests for the return to service of the pitot/static system after a lengthy time on the ground.

The following were cited as additional factors:

- It is possible the flight crew were not physically or mentally rested and prepared to fly the trip due to the unexpected call of the crew during scheduled free time.

- The age of the Captain (62 years) did not allow him to act as pilot in command in certain countries.

- Birgenair's training did not include Crew Resource Management (CRM) and there was a combination of training from outside sources that failed to provide continuity or an integrated approach to attaining the maximum efficiency of the flight crew.

- The Operations Manual of the 757/767 did not contain detailed information to provide the flight crew with a list of appropriate verifications, to signal a discrepancy in the indication of airspeed, simultaneous activation of rudder/mach trim and other EICAS warnings and a flight with an airspeed indicator that may not be trustworthy.

- The EICAS system of the Boeing 757/767 aircraft did not include an alert of "caution or warning" when a signal of erroneous airspeed is detected.

Click here to see the full accident report.

The Dominican Republic Aircraft Accident Investigation Board (JIAA) had the following nine safety recommendations to the International Civil Aviation Organization (ICAO):

- To issue a directive requiring that the flight manual of the Boeing 757/767 be revised to notify the pilots that simultaneous activation of the warnings "MACH/SPD TRIM" and "RUDDER RATIO" may be an indication of discrepancies in airspeed indicators.

- To require Boeing Company to modify the B-757/767 alert system to include "an advisory" (CAUTION ALERT) when an erroneous airspeed is detected.

- To require Boeing Company to modify the Operations Manual of the B-757/767 to include in the emergency procedures section information about "Identification and elimination of an erroneous airspeed indication."

- To issue a Flight Standards Information Bulletin directed to all operations inspectors to assure that the Operations Manuals of B-757/767 operators contain procedures about "Identification and elimination of an erroneous airspeed indication."

- To issue an aeronautical information bulletin notifying the inspectors of the circumstances of this accident, to assure that in training there will be an emphasis on the importance of recognizing a malfunctioning airspeed indicator during the course of takeoff.

- To assure that all training in the B-757/767 includes a scenario flight in the simulator where the pilot is trained to respond appropriately to the effects of a "Blocked Pitot Tube."

- That each air business has a manual of specific training and is specialized for the type of operations specific to that airline without taking into account the generic training of the flight crew offered by businesses dedicated to the sale of training (Academies, schools, etc.).

- To establish as a requirement of all commercial air businesses a program of flight crew training in "Crew Resource Management" (CRM).

- To revise the existing training requirements to gain better efficiency for flight crews.

The U.S. National Transportation Safety Board (NTSB) participated in the investigation and had six recommendations for the FAA that were essentially the same as the first six items above. Click here for the letter.

The relevant regulations for this accident deal mainly with maintenance procedures. Birgenair maintenance manuals from this time period could not be found, but typically airlines will adopt the manuals recommended by the manufacturer. The accident report cited that they thought the procedures were not followed with respect to using pitot tube covers nor with respect to return-to-flight maintenance actions.

In the U.S. this would fall under the Code of Federal Regulations (CFR) 14 (Aeronautics and Space) Federal Aviation Regulation (FAR) Part 43, "Maintenance, Preventive Maintenance, Rebuilding and Alteration." Specifically, paragraph 43.5, "Approval for return to service after maintenance, preventive maintenance, rebuilding or alteration.” The companion operational rule is FAR Part 91, "General Operating and Flight Rules,” paragraph 91.407, "Operations after maintenance, preventive maintenance, rebuilding or alteration."

The accident board cited Birgenair's lack of a formal Crew Resource Management (CRM) training program as an additional factor in this accident. It is not known if this was a requirement of the Turkish regulators at the time of the accident, but it was a formal requirement of the FAA.

Further, manufacturer's maintenance procedures specified that for extended out of service periods (such as extended maintenance), pitot covers should be installed. Additionally, the same maintenance procedures specified that following extended maintenance periods, the pitot-static system should be checked for proper operation prior to airplane return to service. It was established by the investigation that the pitot covers were not installed, and that the pitot-static system was not functionally checked, per the manufacturer's recommended maintenance procedures, before the airplane was returned to service.

The company's failure to follow maintenance procedures.

- The investigation concluded the company did not properly use pitot covers while the aircraft was out of service for 20 days for maintenance.

- The company did not follow the manufacturer's maintenance procedures for an aircraft that was down for maintenance for this length of time prior to return to service.

The captain's failure to follow standard operating procedures.

- The captain did not reject the takeoff upon discovering that his airspeed indicator was not working.

- The captain, once he understood the alternate airspeed indicator was working, failed to use that as his primary source until the crew could diagnose the problem.

- The captain failed to react to the stall warning stick shaker.

- Pitot covers would be installed on an aircraft planned to be out of service for an extended period.

- Prior to return to service, the pitot-static system would be functionally checked.

- The crew would have rejected the takeoff at the first indication of an erroneous airspeed and prevented the airplane from flying.

- Upon recognizing the failure of an airspeed indicating system, the crew would have reverted to the use of the alternate airspeed indicating system.

- The crew would have responded properly to reduce the angle of attack when encountering a stall warning while in flight

The main precursors for this accident were the numerous previous accidents resulting from blocked pitot tubes (see Related Accident/Incident section). Most of these cases were caused by pitot probes icing up when the heater either failed or was not turned on when it should have been. However, the symptoms are the same no matter what plugs the pitot tube.

View Larger

The Birgenair accident is a very important case for Europe. Even though the aircraft was Turkish, it was full of German tourists. The main consequence was the start of the Safety Assessment of Foreign Aircraft (SAFA) program and later the establishment of the blacklist (now called safety list). Below is the first paragraph from the European Directive 2004/36/EC:

"Whereas:

(1) The Resolution on the air disaster off the coast of the Dominican Republic adopted by the European Parliament on 15 February 1996 (OJ C 65, 4.3.1996, p. 172.) highlights the need for the Community to take a more active stance and develop a strategy to improve the safety of its citizens travelling by air or living near airports."

One of the accident board's "additional factors" for the accident was that the operator did not have an established Crew Resource Management (CRM) training program. Previous similar accidents and incidents in the U.S. had led to the publication of FAA Advisory Circular 120-51, Cockpit Resource Management Training. This AC provides guidelines for 14 CFR parts 121 and 135 certificate holders to establish training designed to increase the efficiency with which flight crew members interact in the cockpit by focusing on communication skills, teamwork, task allocation, and decision making. This AC was later revised on February 10, 1993, as AC 120-51A which changed the name to "Crew Resource Management." This AC has been revised several more times and is currently at revision E (AC 120-51E).

As a result of the first three accident board recommendations, Boeing eventually added information into their FCOM discussing what to do when airspeed was suspected to be unreliable. They also added an "Airspeed Unreliable" unannunciated checklist to the crew's Quick Reference Handbook and new "IAS DISAGREE" (Indicated Airspeed) and "ALT DISAGREE" caution messages were added to the EICAS system. Some form of this "Airspeed Unreliable" checklist eventually made its way into the checklists for all other Boeing models, since the procedure is fairly generic. See an example of the checklist to the right.

Airplane Life Cycle:

- Operational

- Maintenance / Repair / Alteration

Accident Threat Categories:

- Crew Resource Management

- Flight Deck Layout / Avionics Confusion

- Incorrect Piloting Technique

Groupings:

- Loss of Control

- Automation

Accident Common Themes:

- Human Error

Organizational Lapses

The investigation revealed the organization had several breakdowns related to their maintenance practices:

- Investigators believe the pitot tube covers were not installed during some period of the aircraft's non-flying down time. This allowed the suspected mud dauber wasp to build a nest inside the captain's pitot tube and essentially be the root cause of the accident.

- The maintenance crew did not do the manufacturer-prescribed pitot static check that was required for an aircraft that was not flying for the amount of time this aircraft was down (20 days).

Human Error

The investigators determined that the crew made several critical errors during the course of this accident. These are described in chronological order below:

- Contrary to standard operating procedures (SOP), the captain continued the takeoff, even though he discovered his airspeed indicator was not working prior to V1, the "decision speed." SOP dictates he should abort the takeoff prior to V1 for any significant aircraft problem.

- Once airborne they were confused with the airspeed indications and did not perform basic diagnosis techniques to determine which airspeed source was correct. Review of the cockpit voice recorder indicated that they did seem to know that the standby airspeed indicator was accurate, but they did not use that to fly by.

- In their diagnosis of the airspeed problem and associated EICAS messages, they tried to reset circuit breakers (unknown which ones they were referring to) which is strictly against the manufacturer's procedures. This just wasted time during the accident sequence.

- Knowing they had some strange airspeed indications; they did not accomplish the "UNRELIABLE AIRSPEED" checklist. If they had, they may have been able to understand what airspeed was correct and use that or have been directed to go to designated pitch and power settings for safe flight.

- The captain did not react to the stall warning stick shaker. It was activated at the same time as they were getting overspeed indications and the crew were confused as to which was correct. They appeared to not understand that the stick shaker is activated by the AOA vanes and not by the airspeed. Had they responded to the stick shaker they may have been able to recover the aircraft or at least had more time to diagnose the situation.

The following is a list of related accidents. It is not an exhaustive list but includes a number of accidents with similar causes to the Birgenair accident.

Scandanavian Airlines Flight 630, 1/30/73, at Oslo-Fornebu Airport (FBU)

This McDonnell Douglas DC-9 crashed during an aborted takeoff following stall warning activation during the rotation. The investigation found that ice had accumulated in the pitot tubes giving false airspeed indications.

Northwest Airlines Flight 6231, 12/1/74, at Stoney Point, New York

This Boeing 727 accident occurred on takeoff from New York JFK airport. This accident was almost identical to the Birgenair accident except the pitot was plugged by icing instead of the suspected insect nest. In this case, like the Birgenair accident, the crew incorrectly responded to incorrect airspeed indications.

View accident report.

Florida Commuter Airlines Flight 65, 9/12/1980, Atlantic Ocean near Grand Bahama Island

This DC-3A crashed into the Atlantic Ocean while approaching the Grand Bahama Island. Although the NTSB could not definitively find a probable cause, they did cite pre-existing discrepancies in the pitot-static system. The initial takeoff was aborted when the pilot reported no airspeed was indicated. Inspections found his pitot probe blocked by a mud dauber nest, which was cleared, and the flight took off without incident.

View accident report.

Air Florida Flight 90, 1/13/1982, Washington National Airport, Washington, D.C

On January 13, 1982, Air Florida Flight 90, a Boeing Model 737-200 series airplane, crashed shortly after takeoff from Washington National Airport, Washington, D.C. Loss of control was determined to be due to reduction in aerodynamic lift resulting from ice and snow that had accumulated on the airplane's wings during prolonged ground operation at National Airport. A major contributor to this accident was a significant engine thrust shortfall believed to be due to anomalous engine thrust indications on both engines caused by engine pressure ratio (EPR) Pt2 probes which were believed to have been plugged with snow and ice during ground operation.

View accident report.

Panorama Flight Service, 7/28/84, Waterville-Robert Lafleur Airport, ME (WVL)

This Learjet 25B overran the end of the runway when the crew aborted the takeoff after an occurrence of stall warning during the takeoff roll. It was found the pitot covers were not removed prior to departure.

Aeroflot, 5/21/86, Approach to Moscow Airport

This Tupolev 154B experienced incorrect airspeed upon descent through rain and clouds during approach. The flight crew erroneously believed the airplane was stalling and pushed into a severe dive. The dive was recovered with a 3.2 G pull-up, and the severely damaged airplane was landed safely. Investigators determined that pitot heat had not been turned on prior to takeoff, and the pitot tubes iced up during the descent.

Continental Airlines Flight 795, 3/2/94, New York - LaGuardia (LGA)

This McDonnell Douglas MD-82 overran the end of the runway when the crew aborted the takeoff after unusual airspeed indications during takeoff roll. The flight crew failed to activate the pitot heat prior to takeoff, leading to clogging of the pitots with ice and snow.

Aero Peru Flight 603, 10/2/96, Lima, Peru (LIM)

This Boeing 757 experienced anomalous airspeed and altitude indications following takeoff. The crew attempted to return to the airport but lost control and crashed. The investigation revealed that a maintenance crew had failed to remove tape that was covering the left side static ports that had been installed when the airplane was washed and polished prior to flight.

Turkish Airlines Flight 5904, 4/7/99, Adana, Turkey

This Boeing 737 took off into poor weather and crashed 9 minutes after takeoff. The investigation concluded that pitot heat had not been properly activated by the crew, resulting in erratic airspeed indications as the pitot iced up. The crew failed to recognize the cause of the erratic airspeed, lost control of the aircraft and did not use other cockpit indications to recover.

FedEx Flight 87, 10/17/99, Subic Bay Airport, Phillipines

This McDonnell Douglas MD-11 landed and overran the runway. The investigation revealed the aircraft experienced erroneous airspeed indications during descent and landing. The crew failed to verify and use the correct airspeed by checking the standby airspeed indicator. The investigation cited clogged pitot drain holes as a contributing factor. Inadequate checklists that did not refer the crew to use the standby airspeed indicator were also cited.

Air France 447, 6/1/2009, Central Atlantic Ocean

This Airbus A330 crashed into the Atlantic Ocean after the crew lost control of the aircraft. The investigation determined the most likely cause of the accident was loss of control due to unreliable airspeed indications. It was concluded that the pitot probes had become clogged with ice while flying through severe icing conditions. This resulted in unreliable airspeed indication which the crew misinterpreted.

View accident report.

Unkown airline, 1/28/2009, out of Accra, Ghana, Africa

The captain of this Boeing 757 noticed an anomalous airspeed indication during takeoff roll. Similar to the Birgenair accident, the captain elected to continue the takeoff. However, in this case, the captain recognized the anomalie and switched his air data source to ALTN. Following takeoff, when the autopilot began behaving erractically, the flight returned to the departure airport and landed uneventfully. Upon subsequent inspection of the aircraft, inspectors found "the remains of a beetle-like creature in the left pitot system."

View incident report.

Etihad Airways, 11/13/2013, Brisbane Airport, Australia

An Airbus A330 aborted a takeoff due to an airspeed failure on the captain's display. After returning to the gate, maintenance was performed, which resulted in replacing the Air Data Inertial Reference Unit. The airplane was re-dispatched, and during the next takeoff, after reaching V1 the crew became aware of an airspeed error but continued the takeoff. The crew declared an emergency and returned to the airfield uneventfully. Inspection of the Captain's pitot probe revealed it was almost completely plugged with material consistent with a mud-dauber nest.

Technical Related Lessons

The flight crew should check and validate primary flight and engine instruments during the low speed (below 80 knots) portion of each takeoff. If any display appears to be unusual or inoperative, the takeoff should be rejected. (Threat Categories: Incorrect Piloting Technique, Flight Deck Layout/Avionics Confusion)

- During the takeoff roll, per procedure, the captain should have aborted the takeoff immediately upon discovery that his airspeed indicator was not operating properly. Instead, he relied on the first officer's airspeed calls and continued the takeoff.

- Once airborne, knowing he had an unreliable airspeed indicator the captain did not look between his 3 sources and fly using the one he deemed correct.

- When he got the stick shaker (impending stall indication) the pilot did not apply standard stall recovery procedures. He was confused with conflicting high and low speed warnings and did not appear to understand that the stick shaker is not commanded from the airspeed, but from the angle-of-attack sensor.

While in flight, a suspected malfunctioning airspeed display should be cross checked with other cockpit displays, including standby displays, in order to determine the appropriate display to use for maintaining safe airspeed. (Threat Category: Incorrect Piloting Technique, Crew Resource Management)

- The flight crew seemed to be aware that airspeed was not being correctly displayed but were confused as to which display(s) were correct. A cross check, or comparison of the three indicators might have resulted in identification of the incorrect indication, and reversion to use of another indicator, or transfer of control between the pilots.

- Human factors studies have shown that when complex, time-critical safety decisions must be made, humans will channel their attention, and situational awareness will degrade, leading to an increase in errors. For this reason, having multiple crewmembers complementing each other is a widely accepted safety aid. In this accident, the investigators cited the lack of crew resource management as a factor in the progression of the accident sequence.

Common Theme Related Lessons

If an aircraft is expected to be out of service for an extended period of time or will be susceptible to pitot system blockage due to severe weather, dust, debris, or insects, pitot covers should be installed to mitigate the possibility of those blockages occurring. (Common Theme: Organizational Lapse)

- The investigation could not positively establish that pitot probe covers were installed for the entire maintenance period. Uncovered pitots allowed the local mud dauber wasp to build a nest in, and clog the captain's pitot probe, resulting in an incorrect airspeed indication during takeoff and climb.

- The prescribed air data system checks were not performed after a prolonged maintenance period. Investigators believed that if the prescribed checks had been performed, the plugged pitot would most probably have been discovered.