Eurocopter AS350B2

EagleMed, LLC, N917EM

Oklahoma City, Oklahoma

February 22, 2013

On February 22, 2013, at approximately 0542 central standard time (CST), an Eurocopter (Airbus Helicopters) AS350B2 (N917EM) helicopter crashed into a parking lot at the Saint Ann Retirement Center in Oklahoma City, Oklahoma after it experienced a loss of engine power. The helicopter air ambulance was dispatched under 14 CFR Part 91 on a repositioning flight to Watonga, Oklahoma and had just departed the Integris Baptist Medical Center heliport (OK19) a few minutes prior to the accident. The weather was reported as clear skies, ten miles visibility, 19 degrees Fahrenheit (F), and winds from the north at 10 knots. The helicopter was substantially damaged by impact forces and most of the structure was burned by a post-crash fire. One pilot, one flight nurse, and one paramedic were onboard. The pilot and flight nurse were fatally injured. The paramedic survived with serious injuries.

The National Transportation Safety Board (NTSB) determined the probable cause of this accident to be the loss of engine power due to engine ice ingestion during initial climb after takeoff in dark night conditions. Contributing to the accident were the lack of an installed engine air inlet cover while the helicopter was parked outside, exposing the aircraft to precipitation and freezing temperatures before the accident. Also contributing was the pilot’s inadequate preflight inspection that failed to detect ice accumulation in the area of the air inlet.

NTSB accident report: CEN13FA174

History of the Flight

At approximately 0538 CST on February 22, 2013, an Eurocopter (Airbus Helicopters) AS350B2 helicopter, N917EM, registered to Wells Fargo Equipment Finance, Inc. and operated by EagleMed LLC, departed the Integris Baptist Hospital heliport (OK19) in Oklahoma City, OK on a Part 91 helicopter air ambulance positioning flight. The helicopter was en route on a direct flight to the Watonga Municipal Hospital to pick up a patient for transfer to the University of Oklahoma Medical Center. SkyConnect satellite data showed the helicopter departing OK19 and gradually climbing and heading to the northwest. A little more than three minutes after departure, the helicopter experienced a loss of engine power and the pilot attempted to make an emergency landing. Three minutes and 30 seconds after departure, at 0542, the SkyConnect data stopped recording. At approximately the same time, surveillance cameras showed that the helicopter impacted the ground at a high rate of descent in the parking lot of Saint Ann Retirement Center, approximately five miles from its departure point. The helicopter immediately burst into flames and came to rest approximately 75 feet away from the point of impact. The pilot and flight nurse were fatally injured in the accident. The paramedic, who survived the accident with severe burns and other serious injuries, was assisted in exiting the burning helicopter by nearby witnesses.

Weather Conditions Leading up to the Accident

The day prior to the accident, the area experienced freezing precipitation and temperatures that fell consistently from a high of 35 degrees F to a low of approximately 19 degrees F. The helicopter was taken out of service due to the adverse weather conditions. No protective covers were installed on the helicopter during this time. Typically, when bad weather was predicted, the helicopter would be parked inside a hangar at a different location. Since the operator normally kept the helicopter inside during inclement weather, they did not keep any protective covers with the helicopter.

According to investigators, after a period of freezing precipitation and in anticipation of a hard freeze, the day prior to the accident at approximately 1430 local time, the base mechanic checked the condition of the helipad and removed the snow and ice that had accumulated on and around the helicopter. He inspected the condition of the helicopter and looked on top of the main rotor, inside the engine inlet, on the canopy, in the exhaust duct, and on the horizontal stabilizer for snow and ice accumulation. The mechanic noted that there was a little bit of residual accumulation in the engine inlet. There was also some accumulation in the exhaust duct that he cleared out. The mechanic noted that during this time it was drizzling and the temperature was above freezing. He was concerned about removing any moisture because the temperature was likely to drop below freezing. The mechanic also expressed his concerns to the pilot who was working the shift prior to the accident flight about precipitation melting in the tail area and refreezing. At about 2200, several hours after this pilot was off her shift, she sent a message to the accident pilot to warn him that ice was accumulating outside and asked him not to fly.

On the morning of the accident, Visual Meteorological Conditions (VMC) prevailed for the flight that was operating under Visual Flight Rules (VFR). The helicopter departed during clear, cold, dark, pre-daylight conditions. The automated weather reporting station at Wiley Post Airport (KPWA), approximately three nautical miles southeast of the accident site, reported weather conditions at 0453 local time as: winds from 340 degrees at ten knots, ten miles visibility, clear skies, temperature 19 degrees F, dew point 12 degrees F, and barometric pressure of 30.02 inches of mercury.

Winter Operations and Ice Ingestion

Eurocopter, EagleMed, and Soloy Aviation Solutions, the Supplemental Type Certificate (STC) holder for the installed engine, published instructions for pilots to check the engine inlet screen and duct for ice and snow that may enter, freeze, and cause an obstruction which could result in an engine surge or flameout. The instructions state that if any ice or snow exists in the vicinity of the air intake, and on either side of the inlet screen, it must be removed prior to operation. They also state to inspect for snow and ice manually and visually inside the air intake duct up to the first stage of the compressor. The surfaces should also be wiped with a rag soaked with isopropyl alcohol. It also lists other areas to be inspected for snow or ice accumulation.

The AS350B2 flight manual supplement for operation in cold weather recommends installing the air intake cover and exhaust nozzle blank after the last flight of the day to prevent ice or snow accumulation. It also states that when the aircraft is parked in an unsheltered area, it is recommended to apply anti-icing additive and to carry out the aircraft parking and mooring procedures defined in the flight manual. A portion of this supplement can be found at the following link.

AS350B2 Rotorcraft Flight Manual Supplement for Operations in Cold Weather

The EagleMed General Operations Manual (GOM) further states that during icing conditions no helicopter may take off with frost, ice, or snow adhering to the rotor blades, windshield, stabilizing or control surfaces; or to any power plant installation; or an airspeed, altimeter, rate of climb, or flight attitude instrument system.

Their GOM defines a "Clean Aircraft Concept" and calls out 14 CFR Part 135.227 Icing conditions: Operating limitations. This concept requires that no person may takeoff for flight when frost, ice, or snow is adhering to the aircraft. The ultimate responsibility for determining whether the aircraft is free from ice, frost, or snow is placed upon the pilot in command. When contaminants are adhering to the aircraft, those contaminants must be removed before takeoff.

Eurocopter previously published Information Notice No. 2302-I-00 regarding engine flameout or damage when the aircraft has been subjected to cold weather in snowy or rainy conditions and parked outside. The Information Notice states that "a turbine engine is susceptible to a 'sudden quantity' of water, snow, or ice, because this quantity (even limited) corresponds to a very high instantaneous concentration exceeding its absorption capacities." The Information Notice contains recommendations for prevention and precautions to be taken in cold weather when temperatures are close to or below freezing.

Hospital Helipad Lighting

Surveillance video from the two evenings prior showed all helipad lights were on and the helipad was completely illuminated. However, hospital surveillance video of the helipad showed that most of the helipad lights were off at the time of the pilot's preflight inspection, immediately before the accident flight. This would have made it more difficult to detect any ice or snow accumulation in the engine air intake.

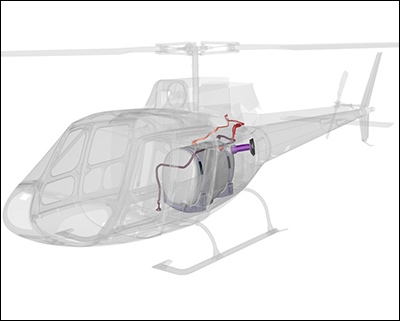

Aircraft Modification

Investigators noted the accident helicopter had been previously modified from its original configuration. It was manufactured with a Turbomeca (Safran) Arriel 1D1 engine. The helicopter was modified by a Soloy STC No. SR01647SE on July 30, 2008 to install a Honeywell LTS-101-700D-2 engine and an air intake duct like that installed on an Eurocopter (Airbus) AS350D helicopter. The original engine air intake was modified for the installation of the Honeywell engine as part of the Soloy STC. According to Soloy, the design of the air intake system used with the STC is virtually identical to the design of the air intake system used on the Eurocopter AS350D model helicopter that is equipped with the Honeywell LTS 101-600A2 engine. The lower air inlet contains a drain hole at the two lowest points to allow for drainage of water. The helicopter did not have the optional inlet air filter kit that could be installed as part of the Soloy STC or a separate STC. It was undetermined by investigators whether the installation of an inlet air filter would have prevented the ingestion of ice or snow in this situation.

Ice Ingestion Requirements

The accident helicopter met the requirements of 14 CFR Part 33.77 and 14 CFR Part 27.1093(b) for ice ingestion and induction system icing protection. The Soloy STC installed on the helicopter also met the requirements of these regulations based on similarity to the AS350D installation.

The requirements in 14 CFR Part 33.77 and 14 CFR Part 27.1093(b) specifically relate to ice or snow that is ingested during the operation of the aircraft while the engine is running. Since the ice or snow accumulated when the accident aircraft was parked, the requirements of this regulation may not have prevented the engine shutdown in this accident.

When an aircraft engine ingests a certain amount of ice or snow it causes a disruption of airflow through the engine. This is known as a surge or compressor stall. The disruption of air also disrupts the combustion of the fuel air mixture in the engine leading to either a momentary or complete loss of engine power. In this accident witnesses described seeing a flash coming from the aircraft prior to the descent to the ground. Investigators concluded this was likely the result of the engine surge from the ice being ingested into the engine.

Engine Auto Relight

The accident helicopter was not equipped, nor was it required to be equipped, with an engine auto relight system. This system attempts to reignite the engine if there is a momentary power interruption. Even with auto relight there is a momentary loss of engine power, and depending on various conditions and the helicopter design, it will likely still lose altitude. In this accident it is likely that the helicopter would not have had enough altitude to allow the engine to come back up to full power before descending to the ground.

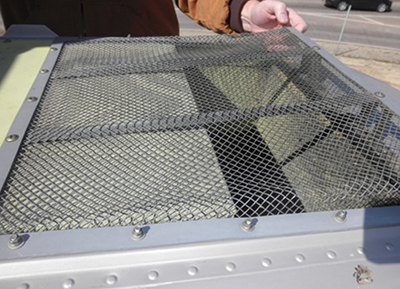

Aircraft Protective Covers

Protective covers are recommended to be used whenever an aircraft is parked and unattended overnight or for more than a few hours. Foreign objects such as ice, snow, foliage, dirt, debris, animals, birds, insects, and other items can enter areas of the aircraft and may be undetected during a preflight inspection. These objects, if not removed before flight, can cause unsafe conditions to exist and lead to catastrophic results. Installing protective covers greatly reduces the possibility of these objects entering flight critical areas such as the engine, pitot tubes, and other systems.

Accident Site

Video from a security camera located on a building near the accident scene confirmed where the aircraft initially impacted the ground as indicated by ground scars. The helicopter was in a righthand bank and eventually came to rest approximately 75 feet away from the point of impact. Upon hitting the ground, the fuel tank ruptured and spilled fuel on the hot engine components, igniting immediately. The aircraft was mostly consumed by the post-crash fire.

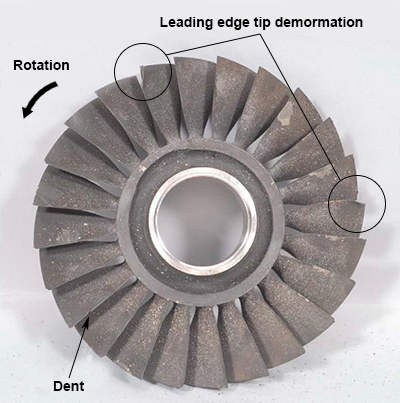

Even though most of the aircraft burned, investigators were able to determine that no significant mechanical issues with the airframe, drivetrain, or flight controls existed prior to the crash. It was however found that several engine compressor blades were damaged and had leading-edge curling at the tips, showing evidence consistent with soft-body, foreign object damage (FOD). This type of damage to the compressor blades was like that found on other turbine engines that have experienced ice ingestion.

Schematic of crash site. Source: NTSB

Post-Crash Fire Resistance

Post-crash fires account for a high percentage of injuries and fatalities in helicopter accidents that would, in the absence of fire, be survivable. The post-impact fire is generally caused by fuel leaks exposed to an ignition source. The development and implementation of crash-resistant fuel systems (CRFS) has shown that technology is available to greatly reduce fire fatalities in otherwise survivable accidents. The FAA has undertaken significant initiatives to reduce the possibility of post-impact fire and in 1991 mandated that all helicopters type certificated after November 2, 1994 have crash-resistant fuel systems per 14 CFR 27.952 "Fuel System Crash Resistance." Even though the accident aircraft was manufactured in 2004, the original certification date for the AS350 helicopter was in 1977; therefore, it was not required to meet these requirements.

CRFS incorporate fuel tanks, lines, fitting, and other components that can sustain the static and dynamic deceleration loads as defined by 14 CFR Part 27.952. The components installed in the helicopter must be capable of surviving an impact when dropped from at least 50 feet with the tanks filled to at least 80 percent. To accomplish this, the CRFS often incorporate the following features: self-sealing breakaway fittings and couplings, impact- and tear-resistant fuel tanks, impact-resistant electrical wires and electrical devices, separation of fuel sources from ignition sources, frangible or deformable attachments and structural components, and vents that prevent fuel spillage during rollover accidents.

Conclusion

The accident occurred just a few minutes after departure from the hospital helipad. The engine experienced a surge and flameout due to ingestion of ice that had accumulated during a period of freezing rain and snow prior to departure from the hospital. The helicopter had been parked outside and did not have protective covers installed to prevent accumulation of ice or snow. The pilot did not perform an adequate preflight inspection and failed to detect the ice or snow that had accumulated in or near the engine inlet. During the emergency autorotation, the helicopter landed hard, causing the fuel tank to rupture. The lack of a crash-resistant fuel system resulted in a post-impact fire that consumed most of the aircraft before it could be extinguished.

The NTSB published the following findings on this accident:

Aircraft powerplant parameters - Attain/maintain not possible – The ingestion of ice in the engine caused a surge that resulted in a flameout and loss of power.

Environmental issues conducive to structural icing - Effect on equipment – The below-freezing temperatures along with freezing precipitation led to ice adhering to and accumulating on the aircraft prior to flight.

Environmental issues dark - Effect on personnel – Since it was dark outside before the flight, visibility likely limited the pilot’s ability to detect ice on the aircraft. While in flight, the dark environment limited the ability for the pilot to choose a suitable landing area while attempting to make an autorotation landing.

Aircraft intake anti-ice, deice - Not used/operated – The helicopter was not equipped with air intake anti-ice and the pilot did not deice the air intake area prior to flight.

Environmental issues low temperature - Effect on equipment – The below-freezing temperatures along with freezing precipitation led to ice adhering to and accumulating on the aircraft prior to flight.

Environmental issues snow - Effect on equipment, personnel issues, preflight inspection - Pilot – The cold temperatures, along with the ice and snow accumulation, made it more difficult to conduct a thorough preflight inspection.

Probable Cause

The NTSB determined that the cause of the accident was attributed to the loss of engine power due to engine ice ingestion during initial climb after takeoff in dark night conditions. Contributing to the accident were the lack of an installed engine air inlet cover while the helicopter was parked outside, exposed to precipitation and freezing temperatures before the accident. Also contributing was the pilot's inadequate preflight inspection that failed to detect ice accumulation around the air inlet.

NTSB accident report: CEN13FA174

14 CFR Part 27.1093(b) Induction system icing protection - Turbine engine

Helicopters equipped with turbine engines must also meet the requirements of 14 CFR Part 27.1093(b) - Induction system icing protection - Turbine engine. This regulation requires manufacturers to show that each engine and its air inlet systems operate throughout the full power range of the engine without accumulating ice, falling snow, or blowing snow on the engine or inlet systems that would adversely affect engine operation or cause loss of power. This regulation specifically relates to the ice or snow that is being accumulated during the operation of the aircraft. Since the ice or snow accumulated when the accident aircraft was parked, the requirements of this regulation would not have prevented the accumulation of ice or snow, nor would it have any effect on the operation of the aircraft or prevented the engine failure in this accident.

14 CFR Part 33.77 Foreign object ingestion - Ice

Aircraft engines must meet the requirements of foreign object ingestion - Ice. Compliance to the regulation must be demonstrated by engine ice ingestion tests or by validated analysis showing equivalence of other means for demonstrating foreign object soft-body damage tolerance. Ingestion of a specified amount of ice may not cause an unacceptable, sustained power loss or require the engine to be shutdown. It is likely in this accident the amount of ice that was ingested exceeded the amount specified in the requirements of 14 CFR Part 33.77.

If an engine incorporates a protection device like an inlet screen or filter, compliance with this regulation does not need to be demonstrated with respect to ice formed forward of the protection device if it is shown that ice is of a size that will not pass through the protective device and the protective device will withstand the impact of the ice. The ice stopped by the protective device must not obstruct the flow of air going into the engine with a sustained reduction in power greater than that specified in the regulation.

Engine ice ingestion tests must simulate the velocity of the ice being sucked into the engine. Also, engine operation will be at the maximum cruise power unless lower power is more critical.

14 CFR Part 91.7 Civil aircraft airworthiness

The pilot in command is responsible for determining whether the aircraft is in condition for safe flight.

14 CFR Part 91.527 Operating in icing conditions

The pilot may not take off if the aircraft has frost, ice, or snow adhering to the powerplant installation or other components such as the propellor or rotor blade, control surfaces, and other specified areas.

SAIB SW-08-03R3 – Dated January 17, 2013, this bulletin is a continued emphasis on rotorcraft and icing conditions that describes procedures to reduce the probability of an engine in-flight failure due to ice or snow ingestion. The SAIB describes that snow or ice can accumulate in the engine intakes and plenums while the aircraft is on the ground with the engine(s) not operating or at a low power setting for an extended period. When the pilot increases the engine power during takeoff, the accumulated snow and ice can separate from the engine air inlet and be ingested by the engine, resulting in a decrease in power or a complete loss of engine power. The SAIB also contains recommendations for the prevention of this issue.

Eurocopter AS350 Flight Manual Supplement

This manufacturer’s document details all procedures to be followed when operating the aircraft in cold weather or snow conditions.

Eurocopter Information Notice No. 2302-I-00 (Revision 1 dated November 3, 2015)

This document specifies the basic precautions to be taken in cold weather before flight, specifically when a helicopter has been subject to cold weather in snowy or rainy conditions and parked in an open environment.

Eurocopter Service Letter No. 1270-00-96

This document specifies the precautions to be taken for the protection and use of helicopters in cold weather and in damp conditions.

Soloy Rotorcraft Flight Manual Supplement (RFMS) No. S2020H, dated January 3, 2012

This supplement contains preflight checks in Section 4.1, titled "Operating Procedures." These preflight checks are like those listed in the AS350B2 flight manual. The engine air intake must be clear of water, snow, and foreign matter. According to Soloy, the AS350B2 flight manual supplement SUP.4 would remain applicable on the actions to take during cold weather operation.

Crash Resistant Fuel Systems

14 CFR Part 21 Certification Procedures for Products and Parts performs multiple functions, including definition of the processes by which aeronautical products are certified. When a manufacturer/modifier applies for a TC or STC, Part 21 establishes the processes that must be followed and the regulations for which compliance must be demonstrated. At TC or STC application, the set of applicable regulations is defined and, in general, remains static for the life of the product.

The various CFR parts, the safety standards associated with airplane or rotorcraft design, are amended on a regular basis, generally to increase the level of safety associated with regulatory requirements. As regulations evolve, an original product is not normally required to comply with later amendments to the applicable regulations. However, if a manufacturer/modifier makes an application to change a certified product, with few exceptions, the changed product is required to show compliance to the regulations in effect at the time of application for the changed areas. Various regulations contained in Part 21 define the certification processes, for any aeronautical product, for which compliance must be demonstrated before a TC or STC is issued.

The accident helicopter did not have a CRFS installed. The original certification basis for the AS350 series did not include a requirement for a CRFS. This regulation was added for new type designs in 1994. 14 CFR Part 21.101 identifies when a type design change (like a later model AS350) would be required to adopt these later safety regulations. The AS350B2 made no changes to the fuel system, and no increase in the certification basis was made.

The requirements for retrofit and forward manufacturing cut-in of CRFS was studied by the FAA during an industry advisory board, the ARAC Rotorcraft Occupant Protection Working Group (ROPWG). The ROPWG recommended a series of occupant protection regulations, including both CRFS and Crash Resistant Seats and Structures (CRSS) be at least partially implemented. Congress mandated the CRFS requirements for operation in the U.S. airspace. The mandate, codified in 49 U.S.C. 44737 (2018), applies to newly manufactured rotorcraft after April 5, 2020.

Regulatory and guidance material related to this accident, at the appropriate amendment levels, is provided in the Related Safety Initiatives section. Links to FAA safety bulletins and the ROPWG reports are also provided.

The manufacturer had not implemented CRFS voluntarily prior to this accident, nor were they required. Designs were in development at the manufacturer, which were implemented later.

14 CFR Part 21.17 Designation of applicable regulations

This regulation was in effect at the time of application for the original type certificate on the AS350 and established the original certification basis. Follow-on derivative models, including the AS350B2, used largely the same certification basis except for areas that were substantially different than the original design and required compliance with newer regulatory amendments. Since the fuel system was not changed as part of the type design, the certification basis for the original equipment manufacturer (OEM) fuel system was not changed for derivative models. At the time of application for the original TC, there were no CRFS requirements applicable for the helicopter.

14 CFR Part 21.115 Applicable requirements

This regulation was in effect at the time of application for the AS350B2. This regulation pertains to STCs, but has the same effect as 21.17, in that it establishes the certification basis for the STC. This regulation also invokes the requirements of 21.101 which requires the adoption of the regulations in effect at the time of application that are directly applicable to the changed areas identified in the STC application.

14 CFR Part 21.101 Designation of applicable regulations

Policy material associated with this regulation explains that 21.101 was adopted to "enhance safety by incorporating the latest requirements into the type certification basis for the changed product to the greatest extent practicable." The original version of this regulation was adopted in 1965. The regulation establishes a means to identify the applicable regulations and their appropriate amendment levels when defining the certification basis of a changed or modified product. The regulation requires the adoption of the regulations in effect at the time of application that are directly applicable to the changed areas identified in the TC amendment application.

14 CFR Part 27.952 Fuel system crash resistance

All helicopters type certificated after November 2, 1994 must have CRFS. The helicopter certification application date, which defines the certification basis, not the manufacturing date, is used to determine the regulatory standards an aircraft must meet. Since most helicopters currently being manufactured in the U.S. have certification basis dates prior to 1994, compliance with later regulatory standards is not mandated, as is this case with the accident aircraft, which was manufactured in 2004.

This regulation states the requirements that must be met by the manufacturer to minimize the hazard of fuel fires to occupants following an otherwise survivable impact (crash landing).

14 CFR 27.561(b)(3) Emergency Landing Conditions - General

Although the rotorcraft may be damaged in emergency landing conditions, it must be designed as prescribed in this section to protect the occupants under those conditions. The structure must be designed to give each occupant every reasonable chance of escaping serious injury in a crash landing.

14 CFR 27.562 Emergency landing dynamic conditions

Although the rotorcraft may be damaged in an emergency crash landing, it must be designed to reasonably protect each occupant when the occupant properly uses the seats, safety belts, and shoulder harnesses provided in the design and the occupant is exposed to the loads resulting from the conditions prescribed in this section.

Advisory Circular 27-1B Certification of Normal Category Rotorcraft

This AC details methods of compliance for both CRFS (AC 27.952) and seat certification (AC 27.562).

Ice Protection

The operator normally moved the helicopter to an enclosed hangar at a different location any time inclement weather was predicted. For this reason, they did not keep protective covers with the aircraft. During the days prior to the accident, the operator did not have the opportunity to fly the helicopter to the location of the hangar. As a result, the aircraft was parked outside without protective covers during the weather event that occurred prior to the accident flight. This allowed ice or snow to accumulate on the aircraft.

Post-crash Fire Prevention

The flying public generally believes that the latest technologies available related to safety are incorporated into aircraft designs as they are in the automotive industry. CRFS technology has existed for many years; therefore, the public expects aircraft to incorporate designs that minimize the likelihood of post-crash fires.

Incorporating CRFS in existing designs and aircraft that are already in service is expensive and greatly increases the cost of the aircraft. As a result, manufacturers, owners, and operators often felt it was not economically feasible to modify or retrofit their aircraft to incorporate CRFS.

Aircraft Stored Outside During Inclement Weather Without Protective Covers Installed – The lack of protective covers allowed snow or ice to accumulate on the aircraft and near the engine intake during inclement weather.

Improper Preflight Inspection – The pilot did not perform a thorough preflight inspection and did not detect and remove snow or ice that had accumulated on the aircraft and near the engine intake.

Dark, Night Operations Risk – This flight involved night operations that created additional risks and increased difficulty associated with preflight checks, autorotation, and routine and emergency procedures.

Post-crash Fire Prevention

No Crash-Resistant Fuel System – No CRFS was installed, nor required. However, a CRFS could have decreased the likelihood of a post-crash fire and potentially improved survivability.

Protective covers are installed on the aircraft while sitting outside during inclement weather.

- No protective covers were installed over the engine air inlet, exhaust duct, pilot tubes, or any other part of the aircraft during the inclement weather. This allowed ice or snow to accumulate in and around the engine inlet.

Pilots thoroughly complete all preflight checklists without error.

- The accident pilot did not perform a thorough preflight inspection of the aircraft prior to the accident flight; therefore, he did not detect the ice or snow that had accumulated around the engine intake.

The following precursor accidents are related based on either ice/snow ingestion or other ice/snow effects on performance of the aircraft.

Eurocopter EC130 B4, Air Methods, N334AM, Seminole, OK, January 2, 2013

During this positioning flight to an accident scene, the pilot heard a sound like something striking the helicopter, which was followed by a loss of engine power. Prior to take off, the pilot removed the inlet cover and performed a walk-around inspection. However, following a flight three days prior, the inlet covers were not installed. During an unknown time of day before the accident, the covers were installed, but this was after drizzle and rain, then mist and fog, had occurred. On the night before the accident, temperatures remained below freezing; however, temperatures reached 39 degrees prior to takeoff. Investigators determined the accident cause to be ice ingestion following the maintenance personnel’s delayed decision to install the engine inlet cover, exposing the aircraft to moisture and freezing temperatures. Contributing was an inadequate preflight check which did not detect the ice formation.

NTSB accident report: CEN13FA121

Eurocopter AS350B3, Royal Canadian Mounted Police, C-FMPG, Cultus Lake, British Columbia, Canada, January 17, 2012

A Royal Canadian Mounted Police helicopter experienced a noise and a puff of grey/white vapor from the engine area, followed by a rapid loss of rotor RPM. The helicopter descended quickly, and within seconds, landed heavily on the snow-covered terrain. Upon impact with the ground, the helicopter fuselage collapsed, and the fuel tank ruptured. There was no fire. The helicopter was destroyed, and the pilot was fatally injured. Protective covers had not been installed on the engine air intake during a period of heavy snow fall and removal of the snow was not accomplished prior to flight. The snow built up in the engine air intake plenum and the helicopter experienced a complete loss of engine power after the snow was ingested into the engine while in flight.

Transportation Safety Board of Canada (TSB) accident report: A12P0008

Bell 407, Air Evac EMS, Inc., N600CE, Decatur, TX, December 25, 2009

At the beginning of a cross-country repositioning flight, the helicopter climbed to about 50 feet when two warning horns sounded. The helicopter then yawed 90 degrees to the left, prompting the pilot to lower the collective and maneuver back to the helipad. While attempting the landing, the helicopter continued a quick decent, experiencing a hard landing. An examination of the engine control unit revealed a momentary flameout and successful relight. Weather the prior day included rain and moderate blowing snow and the helicopter was not flown during the night due to weather conditions that included accumulation of snow/ice on the rotor blades and horizontal stabilizer. Prior to flight, the pilot did a walk around, removed engine covers, and waited for the ice to melt during 39-degree temperatures. Investigators determined that an inadequate preflight inspection and loss of engine power due to snow/ice ingestion to be the probable causes of the accident.

NTSB accident report: CEN10LA078

Hughes 369D, Highline Helicopters, N1088G, Lyman, WA, January 4, 2007

During longline operations, the pilot noticed that the snow had turned wet and heavy. Thus, he decided to halt load movements and move to better weather conditions. However, at the request of the ground crew who said he would pass by another load, the pilot made an additional pickup. As he entered a hover to pick up the load, the helicopter lost power and the pilot had to make an emergency landing. He believed that when he changed the angle of attack to put the hook in the right location, a layer of wet snow and ice crystals lifted off the canopy and entered the particle separator, leading to a flameout. Investigators determined the cause of the accident to be the pilot’s intentional flight into adverse weather conditions which led to snow and ice ingestion and the subsequent loss of engine power during a hover.

NTSB accident report: SEA07LA041

Croman SH-3H, Croman Corporation, N612CK, Ely, NV, January 18, 2006

On a repositioning flight through periodic rime and mixed ice conditions, the pilots heard a loud bang and then the helicopter lost power in both engines. The engine and airframe deice/anti-ice systems were on and functioning. Investigators noted that optional engine inlet ice/snow deflector shields were not installed. Aircraft damage to the number 1 engine and associated parts were consistent with ice ingestion. Probable cause was noted to be ingestion of ice and snow as well as the pilot’s pre-flight and in-flight decisions to fly into areas of known and forecast moderate icing conditions in contradiction to the FAA’s approved type certificate data sheet.

NTSB accident report: LAX06LA092

Bell 206, Kenai Helicopters, N2267N, Grand Canyon, AZ, April 18, 2000

During a preflight check, the pilots cleaned snow from the helicopter using brooms, squeegees, and brushes. Shortly after engine start, warm-up, and takeoff, the pilot heard a bang and sensed a total loss of power. On the day prior, engine inlet or exhaust covers were not installed and the aircraft was parked outside. Weather reports showed that blowing snow conditions occurred periodically during the night. The manual states that should conditions warrant removal of frost or snow, the aircraft will be placed in a covered area until such accumulation is removed and to ensure aircraft surfaces and components are clear of ice and snow, to include air intakes. Investigators determined that the cause of the accident was an inadequate preflight inspection and failure to remove accumulated snow from the engine inlet area.

NTSB accident report: LAX00FA160

The following precursor accidents are related based on post-impact fire due to the lack of CRFS.

Aerospatiale (Airbus Helicopters) AS350D, Island Express Helicopters, N67GE, Avalon, CA, May 24, 2008

The flight was operating under 14 CFR Part 135 as a non-scheduled air taxi flight. As the helicopter approached the shore of Catalina Island it experienced an engine failure. The pilot attempted to perform an autorotation landing and had to clear numerous obstacles, including buildings and power lines, to reach an open field. While attempting to extend his glide, the main rotor RPM decreased and the helicopter crash landed. During the crash, the fuel tank ruptured and the fuel ignited. Three of the six occupants were fatally injured due to the fire.

NTSB accident report: SEA08MA136

Robinson R22B, Helicopter Services, Inc., N281RG, Houston, TX, September 10, 2012

The flight was operating under 14 CFR Part 91 as an aerial photography flight. Investigators determined the probable cause of this accident to be the pilot's failure to maintain control of the helicopter after a loss of engine power. Investigators concluded that the helicopter was operating within the "avoid operation area" (shaded area) of the height-velocity curve. The reason for the loss of engine power could not be determined because examination did not reveal any anomalies that would have precluded operation. The helicopter was not equipped with a CRFS. Upon impact, the helicopter's fuel tank burst, causing fuel to ignite when it contacted hot engine components. Two of the three fatalities were because of thermal injuries from the post-crash fire.

Library module: Helicopter Services Inc., Houston, TX

Several safety initiatives were implemented following this accident.

EagleMed

Blanking plate modification – EagleMed painted the blanking plate adjacent to the air intake screen a matte black color to enhance detection of moisture, including ice formation, which may accumulate on the flat plate.

Revised inspection process – The company modified the inspection process for the engine air intake. Any indications of moisture on the flat plate would result in additional inspections to the air intake area, including opening the engine cowling to ensure a thorough inspection of the air inlet.

Inclusion of intake covers – EagleMed began carrying engine air intake covers in their helicopters at all times.

FAA

SAIB SW-08-03R4 – As a result of this and similar related accidents, the FAA revised and re-released this SAIB on November 26, 2013, providing continued emphasis on precautions to be taken while operating during icing and snowy conditions.

SAIB SW-17-23R2 – This SAIB advises registered owners and operators of certain Airbus Helicopters AS350 and EC130 models of FAA-approved STCs that install CRFS that comply with the latest safety standards. These STCs reduce the risk of post-crash fires and improve occupant survivability in an accident.

SAIB 2023-03R1 – This SAIB provides information to help rotorcraft owners, aircrew, and passengers understand the importance and safety benefits of CRFS for rotorcraft. It also expands the list of safety enhancements available through the voluntary Rotorcraft Safety Promotion Concept. This SAIB is a follow-on to SW-17-31R2.

SAIB SW-17-31R3 – This bulletin notifies all registered helicopter owners and operators of those helicopters that are either:

- 1) fully compliant with the CRFS safety standards of 14 CFR Part 27 through Amendment 27-30 or 14 CFR Part 29 through Amendment 29-35 or

- 2) compliant with the requirements listed in 49 USC § 44737 (2018).

- The statutory requirement of 49 USC 44737 (2018) was established by the FAA Reauthorization Act of 2018 (H.R. 302, Pub. L. 115-254), Section 317, HELICOPTER FUEL SYSTEM SAFETY.

SAFO 19006, Crash-Resistant Fuel System Safety Standards – This SAFO seeks to inform registered owners and operators of helicopters about compliance standards for CRFS.

Eurocopter

Safety Information Notice release – Eurocopter released Safety Information Notice 2645-S-30 on October 31, 2013, regarding ice and rain protection recommendations.

Honeywell

Pilot Advisory Letter release – Honeywell released Pilot Advisory Letter No. PAL TS-01, dated October 8, 2013, recommending that all pilots and flight operations managers review FAA SAIB No. SW-08-3R4.

US Helicopter Safety Team (USHST)

The USHST reviewed 104 fatal accidents from 2009 to 2013 and identified several fatal accidents where pilots failed to conduct proper preflight and walk-around inspections. An adequate preflight inspection is key to determining the aircraft is in condition for safe flight.

H-SE 28 USHST Helicopter Preflight, Final Walk Around, and Postflight Inspection Guidelines

Aviation Rulemaking Advisory Committee (Industry and FAA)

Rotorcraft Occupant Protection Working Group (ROPWG), Final Report 2018-03-15, Crash-Resistant Fuel System – This report contains the ROPWG recommendations for incorporating CRFS regulations into newly manufactured rotorcraft that were certified before these regulations went into effect (legacy helicopters). These recommendations supersede the interim ROPWG proposals submitted on May 11, 2017 and were revised on September 27, 2018.

Congressional Mandate

As a direct result of accidents, and using the ROPWG recommendations, U.S. Congress mandated CRFS requirements through an operational requirement in U.S. airspace for newly manufactured rotorcraft to meet these ROPWG partial list of regulations.

- Codified by H.R. 302 – FAA Reauthorization Act of 2018, Section 317, Helicopter Fuel System Safety

Rotorcraft Life Cycle

- Operational

Accident Threats

- Fire / Smoke (POST-IMPACT) (F-POST)

- Icing (ICE)

- System / Component Failure or Malfunction (powerplant) (SCF–PP)

Industries

- Helicopter Air Ambulance

Accident Common Themes

- Human Error

- Organizational Lapses

Human Error

The pilot failed to perform a thorough and complete preflight inspection including inspecting for ice and snow in and around the engine inlet, exhaust duct, and other areas on the helicopter. Had the pilot checked for ice or snow, he would have found that it existed and would have taken corrective actions.

Organizational Lapses

The operator did not install protective covers on the helicopter. Typically, they relied on moving the aircraft to a hangar at a different location. Since they were unable to move the aircraft prior to this weather event, they did not have a means for covering the aircraft and protecting it from ice or snow accumulation on or around the engine and other flight-critical components and systems.

Airbus Helicopters AS350B3, Air Methods Corporation, N390LG, Frisco, CO, July 3, 2015

While on a public relations mission and immediately after takeoff while climbing, the helicopter began to spin counterclockwise and crashed into a parking lot, impacting a recreational vehicle adjacent to the heliport. Investigators determined the probable causes to be an incomplete preflight hydraulic check, which depleted hydraulic pressure in the tail rotor hydraulic circuit, and the lack of appropriate alerting to the pilot that hydraulic pressure was not restored before takeoff. The pilot did not perform a hover check, as required by operational procedures, which could have allowed the pilot to verify the helicopter’s controllability. Contributing to the severity of the injuries was the helicopter’s fuel system, which was not crash resistant and led to a fuel-fed, post-crash fire.

Library module: Air Methods Corporation, Frisco, CO

Airbus EC130B4, Papillion Airways, Inc., N155GC, Peach Springs, AZ, January 25, 2018

While on an air tour flight in the Grand Canyon, the pilot lost control of the helicopter during gusting, tailwind conditions in an area known for potential downdrafts and crashed in rugged terrain. The helicopter was not equipped with a CRFS and the fuel tank was damaged during the crash. A post-crash fire ignited immediately. The aircraft was destroyed by impact forces and the fire. Five occupants were fatally injured and two occupants were seriously injured.

NTSB accident report: WPR18MA087

Airbus Helicopters AS350B3, Med-Trans Corporation, N851AL, Christmas Valley, OR, May 18, 2022

While transferring a patient from Klamath Falls, OR to Bend, OR, the air ambulance helicopter crashed while trying to land. The helicopter had encountered winds that were approximately 50 mph (43 knots). The pilot was attempting to reposition the helicopter when it began to spin and lost directional control. The helicopter collided with the terrain and rolled onto its side. The tail boom broke off and the helicopter was substantially damaged. The helicopter was equipped with a CRFS. There was no post-crash fire.

NTSB accident report: WPR22LA182

Technical Related Lessons

Accumulation of ice or snow can have serious, detrimental effects on aircraft engine performance and operation. (Threat Category: System / Component Failure or Malfunction (powerplant) (SCF–PP))

- Ice that accumulates in or around the engine intake may come loose during flight and be ingested into the engine. This may disrupt the airflow into the engine and cause a complete loss of power. The ice being ingested can also potentially cause damage to the compressor section.

- In this accident the investigators determined that a large amount of snow or ice had likely accumulated near the engine intake, came loose, and was ingested into the engine while in flight, disrupting the airflow and resulted in a loss of engine power.

- The accident engine met the requirements of 14 CFR Part 33.77 for foreign object ingestion such as ice. The aircraft also met the requirements of 14 CFR Part 27.1093(b); however, since the ice or snow accumulated when the accident aircraft was parked, adherence to the requirements of these regulations would not have prevented the engine failure in this accident.

The risk of post-crash fires from fuel leaks in crashes can be reduced through installation and utilization of crash-resistant fuel systems (CRFS). (Threat Category: Fire/Smoke Post-impact)

- CRFS design requirements increase safety in the event of a survivable crash by either decreasing the likelihood or delaying the onset of post-crash fires.

- The accident aircraft did not incorporate CRFS technology, nor was it required by date of application.

- Special Airworthiness Information Bulletin (SAIB) SW-17-31R2, Fuel System, provides a list notifying all registered owners and operators which helicopters are either fully compliant with the CRFS safety standards or compliant with the 2018 statutory requirement for CRFS design. The statute 49 USC 44737 (2018), effective April 5, 2020, applies to newly manufactured rotorcraft. In addition, the SAIB recommends that owners and operators pursue installation of fuel systems that improve the fuel system crash-resistance capability of their helicopters.

Common Theme Lessons

Pilots should conduct thorough preflight inspections and follow all manufacturer's special inspections when certain conditions exist, such as cold weather, to prevent unforeseen hazards and ensure the aircraft is in condition for safe flight. (Common Theme: Human Error)

- A complete and thorough preflight inspection should prevent unforeseen hazards that may lead to unsafe conditions during flight.

- CFR 14 Part 91.527(a) prohibits an aircraft from taking off with frost, ice, or snow adhering to specified critical components such as the rotor blades, control surfaces, or powerplant installation.

- In addition to the checklist, the preflight may include special precautions found in the flight manual and information notices that the manufacturer has published.

- The aircraft and engine manufacturers specify precautions that should be taken before flight when a helicopter has been subject to cold weather in snowy or rainy conditions and parked in the open.

- The FAA previously published SAIB SW-08-03R3 that describes procedures to reduce the probability of a loss of power and in-flight engine shutdown due to ice or snow ingestion. It contains recommendations for the prevention of such an event.

- In this accident, the pilot failed to perform a proper preflight inspection and did not look for or remove the snow or ice that had accumulated on the aircraft during the inclement weather.

When an aircraft is parked outside for an extended period, operators should use the proper support equipment, such as protective covers recommended by the manufacturer, to prevent snow, ice, or other foreign objects from accumulating in engine inlets, exhaust ducts, pitot tubes, and other areas. (Common Theme: Organizational Lapse)

- Engine inlet and exhaust covers help prevent snow and ice from accumulating in and around the engine inlet.

- Ice that accumulates in and around the engine intake can come loose during flight, be ingested into the engine, and disrupt the airflow, resulting in a loss of engine power or damage to engine components.

- The operator of the accident aircraft normally moved the helicopter to a hangar at a different location during inclement weather but was unable prior to the weather event.

- The accident aircraft sat outside without engine inlet covers installed during a period of inclement weather, resulting in ice accumulation and subsequent engine ingestion.