Boeing 747-400 BCF

Photo copyright Luc Van Belleghem - used with permission

National Airlines Flight 102, N949CA

Bagram, Afghanistan

April 29, 2013

National Airlines Flight 102, a Boeing 747-400 BCF (Boeing Converted Freighter), was a scheduled cargo flight from Bagram Air Base, Bagram, Afghanistan to Dubai, United Arab Emirates on April 29, 2013. During takeoff, the airplane immediately climbed steeply then descended in a manner consistent with an aerodynamic stall and crashed. All seven crewmembers - the captain, first officer, loadmaster, augmented captain and first officer, and two mechanics were killed. The airplane was destroyed by impact and a post-crash fire ensued.

The National Transportation Safety Board (NTSB) determined that the probable cause of this accident was National Airlines’ inadequate procedures for restraining special cargo loads. This resulted in the loadmaster’s improper restraint of the cargo, which moved aft and damaged hydraulic systems Nos. 1 and 2 and horizontal stabilizer drive mechanism components, rendering the airplane uncontrollable. The inadequate procedures: 1) failed to include required, safety-critical restraint information from the airplane manufacturer (Boeing) and the manufacturer of the main deck cargo handling system (Telair) and 2) contained incorrect and unsafe methods for restraining special cargo. Investigators also concluded that a factor contributing to the accident was the failure of the Federal Aviation Administration (FAA) to adequately oversee National Airlines' handling of special cargo loads.

Photo copyright Roger Cannegieter - used with permission

History of Flight

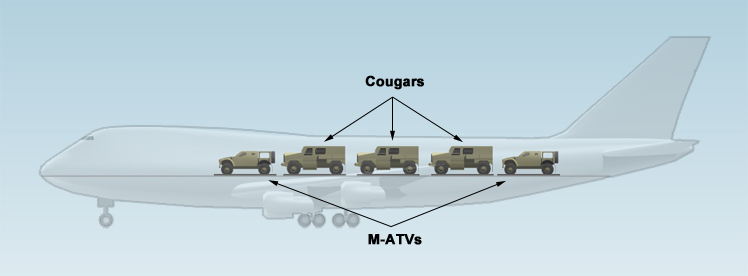

National Airlines Flight 102 was a scheduled cargo flight on April 29, 2013, of a Boeing 747-400 BCF (Boeing Converted Freighter) from Bagram Air Base, Bagram, Afghanistan to Dubai, United Arab Emirates. The airline was transporting military equipment in support of a contract with the U.S. Transportation Command. Included in the cargo were five mine-resistant ambush-protected (MRAP) vehicles comprised of two 12-ton MPRAP-All-Terrain Vehicles (M-ATVs) and three 18-ton Cougars. The MRAPs were being transferred from Camp Bastion, Afghanistan to Dubai, UAE with an intermediate stop at Bagram Air Base. No cargo was loaded or off-loaded at Bagram Air Base.

Investigators learned that during the first segment of the flight from Camp Bastion to Bagram Air Base the flight experienced issues with some tie-down straps. According to the cockpit voice recorder (CVR) transcript, while the airplane was parked on the Bagram Air Base ramp, crewmembers and the loadmaster discussed that some cargo had moved, some tie-down straps had become loose, and one strap had broken sometime during the flight. Although the loose straps were tightened and the broken strap was replaced before takeoff from Bagram, the CVR contains no indication that additional straps were used to secure the MRAPs.

Photo from Air Mobility Command

The investigators examined a video recording of the accident from a moving vehicle's dashboard camera. The accident airplane enters the frame in a steep climb as it departs the runway. The video is available below.

Investigators determined that shortly after rotation during takeoff from Bagram Air Base, at least one MRAP, the aft-most M-ATV, broke loose from its restraints and penetrated the aft pressure bulkhead (APB). It is unknown if other MRAPs also broke loose and moved aft. Before it struck the APB, the unrestrained, aft-most M-ATV impacted the flight data recorder (FDR) and CVR, rendering them both inoperable. This occurred within a few seconds after the airplane left the runway. After the aft-most M-ATV penetrated the APB, hydraulic systems No. 1 and 2 were damaged. The right inboard elevator is powered by systems No. 1 and 2. The elevators control the pitch attitude of the airplane. Performance and wreckage analysis showed the aft-most M-ATV also impacted and severed the horizontal stabilizer jackscrew. The jackscrew is part of the longitudinal trim system, designed to allow pitch control of the airplane. With damage to hydraulic systems No. 1 and 2 and the horizontal stabilizer jackscrew, it was impossible for the flight crew to regain pitch control of the airplane. After rotation, the airplane entered a steep climb. At an altitude of less than 1,000 feet, the airplane pitched up to an extreme attitude and stalled. It rolled slightly to the left, then rolled hard to the right before impacting the ground at a wings-level and nose-down attitude that resulted in a large explosion, fatally injuring all crewmembers.

Key to the investigation was the recovery of several pieces of debris from the runway near the point of takeoff rotation. Debris included small pieces of airplane fuselage skin, a section of hydraulic tubing, a piece of the shelf for the CVR/FDR rack, and part of the aft-most M-ATV antenna assembly. Investigators found orange and green paint transfers consistent with the orange paint on the CVR and the FDR cases and they found green primer used on unpainted airplane structure on the rear portion of the aft-most M-ATV.

An animation of the accident sequence is available below:

Boeing 747-400 BCF Airplane

The Boeing 747-400 BCF, or Boeing Converted Freighter, was a Boeing 747-400 series passenger airplane that was modified in accordance with an FAA-approved Boeing Service Bulletin to operate in a freighter configuration. The modification included new floor beams to strengthen the main deck and a new main deck cargo door and surround structure. The airplane was equipped with a Telair main deck cargo handling (loading and restraint) system as specified in an FAA-approved supplemental type certificate. The Telair cargo restraint equipment included pallet locks, side guide restraints, centerline guide restraints, and retractable and fixed-end stops. All cargo restraining equipment was installed in seat tracks, floor fittings, or within other cargo components. Both Boeing and Telair produced weight and balance manuals. These manuals presented all the weight and balance information necessary to ensure safe airplane operation. In addition, Boeing and Telair provided information to allow the operator to efficiently plan loading procedures in such a manner that maximum payload capability is safely distributed for any type of operation.

Cargo Types and Loading

Photo copyright Steven Fox - used with permission

Standard cargo is usually loaded on a unit load device (ULD) pallet and is secured to the pallet using a net. When the pallet is loaded onto an aircraft, locks in the airplane's cargo handling system restrain forward, aft, side, and up movement.

Special cargo is cargo that is not loaded in a container or enclosed in a cargo compartment certified for bulk loading, but is secured to a pallet. This pallet is termed a "floating pallet" if the tie-down straps are the only means of restraint and require special handling and securing/restraining procedures.

Tall rigid cargo (TRC) is cargo that is taller than 98 inches and will not break apart or conform to the contour of the airplane when subjected to 9Gs-forward during an emergency landing. Both Boeing and Telair weight and balance manuals specify the most-forward location where TRC can be loaded to prevent it from impacting the upper deck passenger compartment.

Tie-Down Requirements

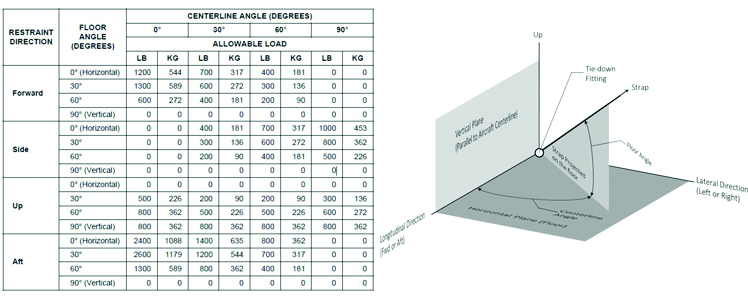

A tie-down is comprised of a strap and a fitting assembly. The straps, when installed, have a maximum rating capability. A tie-down fitting is an attachment device designed to transfer forces between a load-bearing device, such as a strap and a cargo track.

The weight and balance manuals of both the airplane manufacturer and main deck cargo handling system manufacturer state that each tie-down fitting may be used to react load (force magnitude and direction) in only one direction (forward, aft, side, or up). These manuals define allowable loads that can be applied to the attach fittings in terms of 0°, 30°, 60°, and 90° increments when measured relative to both the airplane centerline and airplane floor. Each strap may only be used to react load in one direction; forward, aft, side, or up. The allowable load capability of the fittings varies depending on the measured strap angle and the load-carrying capability of the local structure.

Photo copyright Bob Rogers ULD CARE - used with permission

View Larger

View Larger

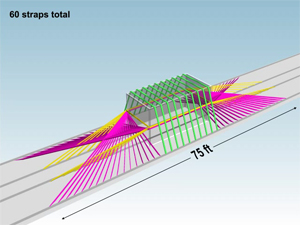

As part of the investigation, a study was performed to determine if it was possible to transport centerline-loaded MRAP vehicles on floating pallets. The study assumed additional cargo would be loaded forward of the vehicles in lieu of restraints to support them in the event of an emergency landing. The study determined that only one centerline-loaded M-ATV (12 tons) on a floating pallet could be transported in accordance with the guidelines in the weight and balance manuals of both the airplane manufacturer and main deck cargo handling system manufacturer. The study determined a single M-ATV must be secured by 60 5,000-lb-rated tie-down straps and no centerline-loaded Cougars (18 tons) could be transported due to structural limitations of the main deck cargo floor.

The study is illustrated in the following animation: National Airlines Load Factor / Restraint Animation. The study also found that no centerline-loaded Cougars on floating pallets could be secured and transported in the airplane in accordance with the weight and balance manual because the vehicle would have to be positioned in an area that would exceed the structural strength limitations of the main deck floor.

Accident Aircraft Cargo Loading

The accident airplane contained both special and tall rigid cargo comprised of five MRAP vehicles. Two of the vehicles were 12-ton M-ATV all-terrain vehicles and three were 18-ton Cougars. The MRAP vehicles were special cargo because their size precluded use of a ULD pallet that would lock into the airplane's cargo handling system. Prior to this flight, no Boeing 747 cargo operator had agreed to transport an 18-ton Cougar.

National Air Cargo (NAC) cargo loaders stationed at Camp Bastion placed the MRAPs on aluminum pallets and used wood blocks as shoring to distribute the weight. The vehicle/pallet unit was loaded through the cargo door in the rear of the fuselage via a lift and conveyor system to move pallets into the airplane. Once inside the cargo door, the loaders moved the units along a series of roller bearings located in the main deck floor. The MRAP pallets were loaded in the centerline position of the main deck. Loaders restrained the MRAPs using 24 5,000-lb-rated tie-down straps for each of the two M-ATVs, and 26 5,000-lb-rated tie-down straps for each of the three Cougars. No main deck floor locks were used on any of the vehicle/pallet units.

The investigation determined that the likely reason for the aft movement of the cargo was that it was improperly restrained. The investigation found that the National Airlines cargo operations manual omitted required, safety-critical restraint information from the weight and balance manuals of both the airplane manufacturer and main deck cargo handling system manufacturer. These omissions included:

- Incorrect and unsafe methods for restraining special cargo;

- Failure to define the individual tie-down allowable loads for the various components in the cargo system, such as the available seat tracks;

- Failure to specify that each tie-down attachment point may be used to react load in only one direction;

- Failure to consider that the allowable load capability of the attach fittings varied depending on the strap angle; and

- Failure to consider the strap angles and tie-down fitting load allowables to calculate the number of straps required to restrain the cargo.

Investigators concluded that, although the aircraft could accommodate the weight of all five vehicles within its weight and balance envelope, no more than one vehicle could be properly secured due to TRC safety requirements.

The National Transportation Safety Board (NTSB) issued ten findings related to this accident. The findings ranged from loadmaster qualifications and training to cargo loading requirements, the airplane's loss of pitch control, and FAA oversight and surveillance of National Airlines' cargo operations.

The complete text of the findings excerpted from the accident report is available at the following link: NTSB Findings

The NTSB issued the following probable cause:

"The National Transportation Safety Board determines that the probable cause of this accident was National Airlines' inadequate procedures for restraining special cargo loads, which resulted in the loadmaster's improper restraint of the cargo, which moved aft and damaged hydraulic systems No. 1 and 2 and horizontal stabilizer drive mechanism components, rendering the airplane uncontrollable. Contributing to the accident was the Federal Aviation Administration's inadequate oversight of National Airlines' handling of special cargo loads."

The entire NTSB accident report is available at the following link: Accident Report

The NTSB issued six recommendations for the FAA:

- To revise the FAA "Air Cargo Operations" Advisory Circular to specify that an operator use FAA-approved data for any planned method for restraining special cargo loads

- To create an FAA certification for cargo loading personnel

- To revise the FAA "National Flight Standards Work Program Guidelines" order to add an item for that air cargo operator inspectors to review their cargo manuals to ensure they are based on FAA-approved data

- To revise the FAA inspector handbook to include specific guidance that defines inspector oversight responsibility for special cargo load handling operations

- To provide special cargo load training for FAA principal inspectors who have oversight of air carrier cargo handling operations

- To implement risk-reduction methods for deferred FAA inspector surveillance tasks

The complete text of the recommendations is available at the following link: NTSB recommendations

Regulations

- 14 CFR Part 21 Certification Procedures for Products and Parts

- 14 CFR Part 25 Airworthiness Standards: Transportation Category Airplanes

- 14 CFR 91.9 Civil Aircraft Flight Manual, Marking, and Placard Requirements.

- 14 CFR Part 119 Certification: Air Carriers and Commercial Operators

- 14 CFR Part 121 Operating Requirements: Domestic, Flag and Supplemental Operations, Sub-part G Manual Requirements

- 14 CFR Part 125 Weights and Measures Envelope and Requirements

Advisory Circulars

- AC 25-5 Installation Approval on Transport Category Airplanes of Cargo Unit Load Devices (later cancelled in 2016)

- AC 25-18 Transport Category Airplanes Modified for Cargo Service

- AC 120-27 Weight and Balance Control (later cancelled in 2016)

- AC 120-85 Air Cargo Operations (later cancelled in 2016)

Operations Specifications

- Operations Specification A002 Definitions and Abbreviations (Mandatory)

National Airlines / NAC Cargo Operations

NAC, the cargo handling vendor for National Airlines, was contracted to load five MRAP vehicles for transport. Two vehicles were 12-ton M-ATV all-terrain vehicles and three were 18-ton Cougars. The MRAP vehicles were considered a special cargo load because the pallets they were on could not be secured in the airplane using the locking capabilities of the airplane's main deck cargo handling system. Instead, the vehicles were attached to specialized pallets restrained to the airplane's main deck floor using tie-down straps.

Two years prior to the accident, the FAA conducted a safety action team (SAT) audit of National Airlines which was allowed under the air transportation oversight system (ATOS). The audit recommended that the airline conduct a voluntary line operations safety audit (LOSA). The airline chose not to do an audit nor a risk analysis on the transport of heavy vehicle special cargo loads. The NTSB investigation concluded that National Airlines' cargo operations manual omitted required, safety-critical information from both the airplane manufacturer and main deck cargo handling system manufacturer. The manual also contained incorrect and unsafe methods for restraining a special cargo load. The NAC loadmaster did not have adequate procedures for securing a special cargo load, and his training was provided by National Airlines, which had developed the inadequate procedures.

FAA Inspections of National Airlines

Investigators determined that FAA inspectors assigned to National Airlines were not provided adequate training and guidance to ensure appropriate oversight of operators who transport special cargo loads. The inspectors assigned to National Airlines were unaware of the airline's deficient procedures. Although the Principal Operations Inspector (POI) learned in early 2013 that National Airlines was carrying heavy loads on pallets, the FAA did not perform a risk analysis. In prior inspections, the FAA failed to determine that National's cargo manual omitted required, safety-critical information from the weight and balance manuals of both the airplane and cargo handling system manufacturers.

- Failure by National Airlines to understand that limitations in an operator's cargo manual cannot be less restrictive than those defined in the aircraft manufacturer's weight and balance manual and main deck cargo handling system manufacturer's manual

- Failure by National Airlines to accurately determine the allowable load-carrying capability of cargo restraint systems and correctly apply any system limitations

- Failure by the FAA to provide their inspectors sufficient training on correct procedures for securing a special cargo load

- Poor coordination of multiple government agencies interfered with the FAA's ability to conduct proper surveillance

Cargo operations manuals contain required and correct information regarding special cargo restraints.

- National Airlines' cargo operations manual omitted required safety-critical restraint information from the weight and balance manuals of the airplane manufacturer and the main deck cargo handling system manufacturer's manual

An aircraft's special cargo is properly loaded and restrained.

- National Airline's procedures for securing special cargo loads were not followed even though the procedures themselves were incorrect, so that if followed, the steps taken would have resulted in improper loading and restraining of special cargo

FAA oversight of an air carrier includes ensuring that inspectors are properly trained on special cargo loads.

- The FAA's safety inspectors responsible for oversight of National Airlines' cargo operations were not sufficiently trained on correct procedures for special cargo loads

Independent government agencies will coordinate and collaborate with each other to determine proper authority and oversight of air carriers conducting supplemental military cargo operations.

- The Department of Transportation (FAA), Department of State, and Department of Defense did not come to agreement on proper coordination of National Airlines' cargo operation

Previous Cargo Movement Event with Horizontal Stabilizer Component Damage

On February 2, 2008, a Boeing 747-200 freighter operated by Atlas Air experienced an aft movement of cargo during takeoff rotation in Lome, Togo, Africa. The cargo, an oil well drill shaft, moved aft, broke through its wooden container, created an 8-inch diameter hole in the aft pressure bulkhead, and became lodged in the tail section of the airplane. The flight crew climbed the airplane to cruise altitude but had difficulties maintaining airplane pressurization. They returned the airplane to the departure airport and landed it safely. Examination of the airplane found that the horizontal stabilizer jackscrew support structure was bent.

Following this accident, the FAA and industry undertook numerous cargo safety initiatives, including reexamination of existing safety requirements and policies, formation of focus teams, delineation of responsibilities of principal inspectors, and creation and enhancement of various training programs. Actions taken by the FAA and industry encompassed:

FAA Actions

Cargo Focus Team - In June 2013, the FAA Flight Standards Service and Aircraft Certification Service formed a Cargo Focus Team (CFT). The mission of the CFT is to directly support FAA field personnel and act as a focal point for the integrity of air cargo operations, while serving as the FAA's technical matter expert in air cargo operations. The CFT is currently required to evaluate weight and balance programs (WBP) using the safety assurance system (SAS) certificate holder evaluation process (CHEP).

Safety Alert for Operators (SAFO) - SAFO 13005, Title 14 of the Code of Federal Regulations 14 CFR Part 121 Air Carriers Transporting Heavy Vehicle Special Cargo Loads, advises cargo operators of the potential safety impact of carrying and restraining heavy vehicle special cargo loads. SAFO 13008, Part 121 Air Carriers Performing Special Cargo Loads Operations for uploading, recommends tie-down procedures for restraining special cargo loads

Advisory Circulars - AC 120-85, Air Cargo Operations was revised to enhance guidance in several areas, including training, special cargo, and restraint. This effort was in response to the NTSB recommendation (A-15-13) to revise the guidance material in AC 120-85 to specify that an operator should obtain FAA-approved data for any planned method for restraining a special cargo load. The revised AC is available at the following link: (AC 120-85A)

Information for Operators (InFO) 13012 - FAA-approved Boeing 747 Sample Weight and Balance Manual (WBM) on November 21, 2013, was developed to inform 747 operators about Boeing's weight and balance manual revisions.

Notices - Notice N8900.262, Review of Weight and Balance Control Programs Including Special Cargo Operations was issued on February 6, 2014. This was issued to inform FAA inspectors about the support functions of the CFT, which includes reviewing their air cargo manuals.

Notice N8900.472, Delineation of Responsibilities for Principal Inspectors Relating to Evaluating a Weight and Balance Program, Cargo Operations, and Surveillance, was issued on October 17, 2018, to provide guidance to principal inspectors on the process of accepting and/or revising manuals and changes to manuals in connection with WBPs, cargo loading, and surveillance of those programs. This effort was in response to the NTSB recommendation (A-15-16) to include specific guidance in the FAA inspector handbook that defines inspector oversight responsibility for special cargo load handling operations.

Training Course - FAA revised some of the content of the air cargo training course for new inspectors.

Job Aids - Weight and balance job aids for inspectors regarding load control and cargo loading were developed (N8900.1 Volume 6, Chapter 2, Section 5 - Safety Assurance System: Conduct a Ramp Inspection on Cargo Loading for Parts 121, 125, 135, and 91).

Industry Actions

National Airlines - Following the accident, National Airlines revised their cargo operations manual to incorporate cargo restraint information from the weight and balance manuals of both the airplane manufacturer and main deck cargo handling system manufacturer. They created a special cargo loads team to perform a comprehensive evaluation of planned cargo loads. They produced training materials for crews, worked with NACA and Boeing to standardize the cargo industry with respect to aircraft manufacturer guidelines, national loadmasters attended Boeing formal training, and the airline defined when audits and training are required.

NACA - Assisted FAA with SAFOs, focus teams, ACs, worked with Boeing and FAA to develop industry best practices, held special cargo load meetings, plus on-going activities.

Boeing - Changed weight and balance manuals, increased training, supported NACA meetings regarding special cargo.

IATA - Conducted forums to address special cargo load safety and on-going activities.

Airplane Life Cycle:

- Operational

Accident Threat Categories:

- Cabin Safety / Hazardous Cargo

- Structural Failure

- In-flight Upsets

Groupings:

- Loss of Control

Accident Common Themes:

- Organizational Lapses

- Human Error

- Flawed Assumptions

- Pre-existing Failures

Organizational Lapses

Oversight of National Airlines

NAC, the cargo-handling vendor for National Airlines, was contracted to load five MRAP vehicles for transport. The MRAP vehicles were considered a special cargo load because they could not be restrained in the airplane using the locking capabilities of the airplane's main deck cargo handling system. Instead, the vehicles were restrained to the airplane's main deck floor using tie-down straps. Investigators concluded that the FAA did not ensure the National Airlines cargo manual reflected the correct information and guidance that specified how to safely secure the cargo. Investigators determined that FAA inspectors were not equipped with adequate tools and training to ensure proper oversight of an air carrier's procedures for restraining special cargo, and that those procedures should be based on airplane manufacturer STC or other FAA-approved data. In addition, it was learned that National Airlines failed to provide training and a proper manual to its ground operations vendor. Also, following an FAA safety action team audit, the airline did not conduct a voluntary line operations safety audit (LOSA) nor conduct a safety risk analysis of heavy vehicle special loads.

Multiple Government Agencies

State Department restrictions prevented the FAA from conducting proper safety oversight. Department of Defense contracts presented unique operator oversight challenges. Lack of proper integration of multi-level agency roles resulted in confusion and ambiguity of oversight duties.

The following 208 accidents/hull losses are attributed to cargo. The accidents have been grouped into three categories: center of gravity; cargo shift; and cargo overload. These lists are not comprehensive.

| Date | Type | Operator | Fatalities | Location |

|---|---|---|---|---|

| 30-Oct-47 | Lockheed 414-08 Hudson IVA | John Fairfax & Sons | 2 | Australia |

| 18-Apr-48 | Lockheed 414-56 Hudson IIIA | Guinea Air Traders | 37 | P.N. Guinea |

| 10-Mar-49 | Lockheed 18 Lodestar | Queensland Airlines | 21 | Australia |

| 12-Mar-50 | Avro 689 Tudor 5 | Fairflight | 80 | U.K. |

| 11-Dec-57 | DHC-3 Otter | Philippine Air Lines | 2 | Philippines |

| 19-Jun-62 | Douglas DC-3D | Swissair | 0 | Switzerland |

| 23-Aug-62 | Douglas R4D-1 (DC-3) | Líneas Aéreas Taxader | 12 | Colombia |

| 15-Sep-64 | Douglas C-47A (DC-3) | Avianca | 2 | Colombia |

| 7-Sep-65 | Lockheed PV-2 Harpoon | Micronesian Airlines | 2 | USA |

| 12-Sep-66 | Douglas DC-7CF | Airlift Int. | 0 | Japan |

| 28-Feb-67 | Fokker F-27 Friendship 100 | Philippine Air Lines | 12 | Philippines |

| 16-Oct-70 | Lisunov Li-2 | Aeroflot / Northern | 0 | Russia |

| 27-Aug-71 | Volpar Turboliner | Chicago & Southern Airlines | 1 | USA |

| 15-Dec-73 | Lockheed L-1049H Super Constellation | Aircraft Pool Leasing Corp. | 3+6 | USA |

| 22-Feb-74 | Curtiss C-46A | SAVCO | 7 | Bolivia |

| 9-Dec-74 | Antonov An-2T | Aeroflot / East Siberia | 0 | Russia |

| 6-Jun-76 | GAF Nomad N.22B | Sabah Air | 11 | Malaysia |

| 21-Aug-76 | Convair CV-880 | Airtrust Singapore | 0 | Singapore |

| 16-Dec-76 | Convair CV-880 | Air Trine Inc | 0 | USA |

| 13-Dec-77 | Douglas C-53 (DC-3) | Air Indiana | 29 | USA |

| 25-May-78 | Convair CV-880 | Groth Air | 0 | USA |

| 8-Oct-80 | Tupolev Tu-154B-2 | Aeroflot / Far East | 0 | Russia |

| 9-Jul-81 | Howard 500 | Kelowna Flightcraft | 3 | Canada |

| 16-May-82 | DHC-6 Twin Otter 200 | Kodiak Aviation, op.for Wien Air Alaska | 0 | USA |

| 12-Apr-83 | Antonov An-26 | Aeroflot / Belarus | 0 | Belarus |

| 22-Jun-83 | Douglas C-47A (DC-3) | Skycraft Air Transport | 2 | Canada |

| 18-Dec-84 | Antonov An-2 | Aeroflot / Krasnoyarsk | 0 | Russia |

| 28-Aug-86 | Howard 250 | Southwest Airlift | 2 | USA |

| 23-Nov-87 | Beech 1900C | Ryan Air Service | 18 | USA |

| 23-May-88 | Boeing 727-22 | LACSA | 0 | Costa Rica |

| 24-Sep-88 | Tupolev Tu-154B-2 | Aeroflot / Armenia | 0 | Syria |

| 13-Dec-88 | Antonov An-2R | Aeroflot / Arkhangelsk | 0 | Russia |

| 13-Jan-89 | Tupolev Tu-154S | Aeroflot / International | 0 | Liberia |

| 8-May-89 | Beech 99 | Holmström Flyg | 16 | Sweden |

| 13-Apr-90 | Antonov An-2 | Aeroflot / Magadan | 1 | Russia |

| 20-Oct-90 | Tupolev Tu-154B-1 | Aeroflot / Georgia | 0 | Georgia |

| 22-Dec-91 | Douglas DC-3A | Classic Wings | 28 | Germany |

| 13-Jul-92 | Shorts SC.7 Skyvan 3A-200 | Arctic Circle Air Service | 1 | USA |

| 20-Jul-92 | Tupolev Tu-154B | Tbilisi Aviation Enterprise | 24+4 | Georgia |

| 13-Oct-92 | Tupolev Tu-154B-2 | Aeroflot / Belarus | 0 | Russia |

| 10-Dec-92 | Volpar Turboliner II | Connie Kalitta | 1 | USA |

| 21-Jan-93 | Antonov An-2T | DOSAAF | 0 | Russia |

| 26-Aug-93 | Let L-410UVP-E | Sakha Avia | 24 | Russia |

| 17-Aug-95 | BN-2A Islander | Barak Aviation Services | 0 | Israel |

| 5-Dec-95 | Antonov An-2R | Kotlas Avia Enterprise | 0 | Russia |

| 7-Aug-97 | DC-8-61F | Fine Air | 4+1 | USA |

| 13-Aug-97 | Beech 1900C | Ameriflight | 0 | USA |

| 17-Dec-97 | Ilyushin Il-18V | Ramaer Cargo | 0 | South Africa |

| 3-Dec-98 | BAe-748 | Bradley Air Services | 0 | Canada |

| 12-Jan-99 | Fokker F-27 Friendship 600 | Channel Express | 2 | U.K. |

| 15-Jan-00 | Let L-410UVP-E | TACSA | 5 | Costa Rica |

| 17-Mar-00 | Douglas C-47A (DC-3) | Points North Air Services | 2 | Canada |

| 10-Oct-00 | Canadair Challenger 604 | Bombardier | 2 | USA |

| 3-Mar-01 | Shorts C-23B+ Sherpa (330) | Florida ANG | 21 | USA |

| 18-Sep-01 | Let L-410UVP-E | Atlantic Airlines | 8 | Guatemala |

| 3-Nov-01 | Cessna F406 Caravan II | GJ Air | 3 | South Africa |

| 13-Apr-02 | GAF Nomad N.24A | Nomad Fleet | 0 | U.K. |

| 1-Mar-03 | Let L-410UVP | Borki Air Club | 11 | Russia |

| 17-Jun-03 | MD-88 | Onur Air | 0 | Netherlands |

| 25-Dec-03 | Boeing 727-223 | UTA | 141 | Benin |

| 18-May-04 | Antonov An-2P | Araiavia | 1 | Kazakhstan |

| 11-Dec-04 | Embraer EMB-110 Bandeirante | NHR Táxi-Aéreo | 2+1 | Brazil |

| 2-Feb-05 | Canadair CL-600 Challenger 600 | DDH Aviation, op.for Platinum Jet Mgmt | 0 | USA |

| 6-Feb-05 | DHC-8-315 Q300 | Air Sénégal International | 0 | Senegal |

| 7-Jul-13 | DHC-3T Texas Turbine Otter | Rediske Air | 10 | USA |

| 19-Oct-13 | ATR 42-320F | Farnair Switzerland, op.for Air Niugini | 0 | P.N. Guinea |

| 2-Jul-15 | DHC-6 Twin Otter 300 | Trans Maldivian Airways | 0 | Maldives |

| 15-Sep-15 | DHC-3T Texas Turbine Otter | Rainbow King Lodge | 3 | USA |

| 2-Nov-15 | MD-80 | Everts Air Cargo | 0 | Mexico |

| Date | Type | Operator | Fatalities | Location |

|---|---|---|---|---|

| 8-Aug-43 | Lisunov PS-84 | Aeroflot | 6 | Russia |

| 29-Jan-49 | Lisunov Li-2T | Aeroflot / Northern | 3 | Russia |

| 13-Feb-56 | Bristol 170 Freighter 31 | Maritime Central Airways | 3 | Canada |

| 24-Nov-58 | Antonov An-2 | Aeroflot / Magadan | 0 | Russia |

| 15-Dec-61 | Curtiss C-46 | LANICA | 2 | Nicaragua |

| 6-Jan-67 | Curtiss C-46F | Channel Air Lift | 3 | USA |

| 2-Jul-70 | Shorts SC.7 Skyvan 3-200 | Jetco | 2 | USA |

| 20-Nov-77 | Bristol 170 Freighter 31M | Norcanair | 1 | Canada |

| 25-May-79 | DHC-4A Caribou | Sea Airmotive | 3 | USA |

| 7-Feb-81 | Tupolev Tu-104A | Soviet Navy | 50 | Russia |

| 22-Jun-83 | Douglas C-47A (DC-3) | Skycraft Air Transport | 2 | Canada |

| 11-Oct-83 | Boeing 747-249F | Flying Tiger Line | 0 | Germany |

| 30-Jul-87 | Boeing C-97G Stratofreighter | Belize Air Int. | 5+44 | Mexico |

| 13-Jan-89 | Tupolev Tu-154S | Aeroflot / International | 0 | Liberia |

| 18-Jan-89 | Douglas C-47A (DC-3) | American Air Freight | 0 | USA |

| 26-Apr-89 | SE-210 Caravelle 11R | Aerosucre Colombia | 5+2 | Colombia |

| 13-Jul-92 | Shorts SC.7 Skyvan 3A-200 | Arctic Circle Air Service | 1 | USA |

| 10-Dec-92 | Volpar Turboliner II | Connie Kalitta | 1 | USA |

| 16-Jun-93 | DHC-6 Twin Otter 300 | Merpati Nusantara | 1 | Indonesia |

| 28-Jan-95 | Boeing 747-238B | Kalitta American International Airways | 0 | USA |

| 2-Feb-08 | Boeing 747-200 | Atlas Air | 0 | Africa |

| 29-Apr-13 | Boeing 747-428BCF | National Airlines (National Air Cargo) | 7 | Afghanistan |

| 26-Nov-13 | Boeing 737-330 | Aloha Air Cargo | 0 | USA |

| 16-Oct-14 | Douglas C-118A Liftmaster (DC-6A) | Everts Air Cargo | 0 | USA |

| 10-Dec-17 | Boeing 737-200 | Northern Air Cargo | 0 | USA |

| 23-Dec-17 | Douglas DC-9-30 | Everts Air Cargo | 0 | USA |

| Date | Type | Operator | Fatalities | Location |

|---|---|---|---|---|

| 3-Oct-41 | Lisunov PS-84 | Aeroflot | 1 | Russia |

| 8-Oct-41 | Junkers Ju-52/3m | German AF | 0 | Norway |

| 23-Oct-41 | Douglas DC-2-112 | RAF | 0 | Pakistan |

| 15-Jan-42 | Consolidated PBY-5 Catalina | RAAF | 9 | P.N. Guinea |

| 14-Mar-42 | Douglas DC-2-221 | CNAC | 13 | China |

| 25-May-42 | Douglas C-39 (DC-2) | USAAF | 10 | Australia |

| 11-Nov-42 | Douglas C-47 (DC-3) | USAAF | Gibraltar | |

| 30-Jun-43 | Lockheed 414 Hudson VI | RAF, op.for BOAC | 16 | Sudan |

| 14-Dec-43 | Douglas C-47 (DC-3) | RAAF | 0 | Australia |

| 28-Mar-46 | Kawasaki Ki-56 | Dalstroi Aviation | 1 | Russia |

| 16-Jun-47 | Lisunov Li-2 | Aeroflot / Kazakstan | 3 | Tajikistan |

| 24-Nov-47 | Ilyushin Il-12P | Aeroflot / Moscow | 0 | Russia |

| 23-Dec-47 | Douglas DC-3C | Coastal Air Lines | 0 | USA |

| 25-Oct-48 | Lisunov Li-2 | Aeroflot / Georgia | 18 | Russia |

| 7-Jun-49 | Curtiss C-46D | Strato-Freight | 53 | Puerto Rico |

| 20-Nov-49 | Short Sunderland GR.5 | RAF | 5 | Singapore |

| 5-Apr-50 | Douglas C-47A (DC-3) | Deccan Airways | 3 | India |

| 4-Jan-51 | Curtiss C-46D | Monarch Air Service | 0 | USA |

| 27-Oct-53 | Ilyushin Il-12 | Aeroflot / Far East | 22 | Russia |

| 7-Jun-55 | Lockheed 14-08 Super Electra | Associated Airways | 6 | Canada |

| 22-Mar-58 | Lockheed 18 Lodestar | Ayer Lease Plan, op.for private | 4 | USA |

| 18-Feb-59 | Curtiss C-46A | Southern Cross Airways | 0 | Chile |

| 24-Dec-59 | Douglas C-47A (DC-3) | Garuda | 1 | Indonesia |

| 29-Oct-60 | Curtiss C-46F | Arctic Pacific | 22 | USA |

| 6-Jan-62 | Curtiss C-46A | TAN | 1 | Belize |

| 22-Nov-62 | Douglas C-54D (DC-4) | Portuguese AF | 22 | Sao Tome |

| 20-Oct-65 | Douglas C-47A (DC-3) | Philippine Air Lines | 1 | Philippines |

| 12-Dec-65 | Learjet 23 | private | 1 | Switzerland |

| 17-Sep-66 | Lockheed 14-N3 Super Electra | Thunderbird Airways | 0 | USA |

| 13-Feb-69 | Curtiss C-46D | Aeropesca Colombia | 0 | Colombia |

| 18-Feb-69 | Douglas C-47A (DC-3) | Indian Airlines | 0 | India |

| 16-Oct-70 | Lisunov Li-2 | Aeroflot / Northern | 0 | Russia |

| 24-May-71 | Antonov An-2T | Aeroflot / Uralsk | 0 | Russia |

| 17-Oct-71 | Douglas C-47A (DC-3) | Aerolíneas TAO | 19 | Colombia |

| 29-Dec-71 | Antonov An-2V | Aeroflot / Tyumen | 0 | Russia |

| 31-Dec-72 | Douglas DC-7CF | American Express Leasing | 5 | Puerto Rico |

| 8-Mar-73 | Douglas C-47J (DC-3) | US Army | 14 | USA |

| 14-May-73 | Antonov An-2R | Aeroflot / Northern | 0 | Russia |

| 16-Oct-73 | Boeing 707-327C | TMA | 0 | India |

| 25-Oct-73 | Antonov An-2R | Aeroflot / Uralsk | 0 | Russia |

| 5-Mar-74 | Grumman G-73 Mallard | North Coast Air Services | 3 | Canada |

| 27-Dec-74 | Antonov An-2R | Aeroflot / Far East | 0 | Russia |

| 26-Apr-75 | Beech A100 King Air | Stribling-Puckett, Inc | 6 | USA |

| 27-Oct-75 | Convair CV-440-12 | TAM | 67 | Bolivia |

| 16-Mar-76 | Beech 99A | Command Airways | 0 | USA |

| 14-Jul-76 | Lisunov Li-2 | MAP Kazan APO | 0 | Uzbekistan |

| 17-Jul-76 | Tupolev Tu-104A | Aeroflot / East Siberia | 0 | Russia |

| 2-Aug-77 | Antonov An-2TP | Aeroflot / Privolzhsk | 0 | Russia |

| 23-Dec-77 | Antonov An-2R | Aeroflot / Far East | 0 | Russia |

| 13-Oct-78 | Antonov An-2R | Aeroflot / Turkmenistan | 0 | Turkmenistan |

| 10-May-79 | Antonov An-2R | Aeroflot / Ukraine | 0 | Ukraine |

| 24-Jul-79 | de Havilland DH-114 Heron 2D | Prinair | 8 | U.S. Virgin Isl. |

| 13-Nov-79 | Curtiss C-46F | Lambair | 0 | Canada |

| 24-May-80 | Convair CV-240-0 | private | 3 | USA |

| 2-Sep-81 | Embraer EMB-110P1 Bandeirante | El Venado | 21 | Colombia |

| 31-Oct-81 | DHC-6 Twin Otter 300 | Cameroon Airlines | 1 | Cameroon |

| 23-Dec-82 | Antonov An-26 | Aeroflot / Turkmenistan | 16 | Russia |

| 15-Feb-83 | Douglas DC-3 | Ontario Central Airlines | 0 | Canada |

| 12-Aug-83 | Antonov An-2R | Aeroflot / Ukraine | 0 | Ukraine |

| 25-Aug-83 | Yakovlev Yak-40K | MAP Arsenyev | 0 | Russia |

| 17-Dec-83 | DHC-6 Twin Otter 200 | Inuvik Coastal Airways | 2 | Canada |

| 2-Aug-84 | BN-2A Islander | Vieques Air Link | 9 | Puerto Rico |

| 16-Sep-84 | Antonov An-2T | APRL | 11 | Poland |

| 21-May-85 | Antonov An-2 | Aeroflot / Tyumen | 0 | Russia |

| 20-Jun-85 | Antonov An-2TP | Aeroflot / Yakutsk | 0 | Russia |

| 4-Jul-85 | Antonov An-2R | Aeroflot / Krasnoyarsk | 0 | Russia |

| 29-Oct-86 | DHC-3 Otter | private | 1 | Puerto Rico |

| 31-Mar-87 | Antonov An-2P | ZUA | 2 | Hungary |

| 2-Jan-90 | CASA/Nurtanio NC-212 Aviocar | Pelita Air Service | 9 | Indonesia |

| 29-Jan-90 | Cessna 208B Grand Caravan | Airborne Express | 2 | USA |

| 6-Apr-90 | Learjet 25C | Transamérica Táxi Aéreo | 2 | Brazil |

| 13-Apr-90 | Antonov An-2 | Aeroflot / Magadan | 1 | Russia |

| 16-Sep-91 | Antonov An-74 | Antonov Design Bureau | 13 | Russia |

| 20-Jul-92 | Tupolev Tu-154B | Tbilisi Aviation Enterprise | 24+4 | Georgia |

| 11-Nov-92 | Antonov An-22A | Soviet AF | 33 | Russia |

| 28-Aug-93 | Yakovlev Yak-40 | Tajikistan Airlines | 82 | Tajikistan |

| 26-Dec-93 | Antonov An-26B | Kuban Airlines | 35 | Armenia |

| 29-Sep-94 | Rockwell 1121B Jet Commander | Radeair | 8 | Argentina |

| 29-Oct-94 | Antonov An-2R | Yakutavia | 7 | Russia |

| 24-Nov-94 | DHC-6 Twin Otter 300 | Kenn Borek Air | 4 | Antarctica |

| 21-Jan-95 | Tupolev Tu-154B-2 | Kazakhstan Airlines | 0 | Pakistan |

| 5-Dec-95 | Antonov An-2R | Kotlas Avia Enterprise | 0 | Russia |

| 18-Dec-95 | Lockheed L-188C Electra | Trans Service Airlift | 141 | Angola |

| 1-May-96 | Boeing 727-2B6 | Fly Linhas Aéreas | 0 | Ecuador |

| 27-Nov-96 | Ilyushin Il-76MD | Russian AF | 23 | Russia |

| 30-Nov-96 | DHC-6 Twin Otter 300 | ACES | 14 | Colombia |

| 25-Jun-97 | Boeing 727-21F | Aerosucre Colombia | 0 | Colombia |

| 30-Jun-97 | Convair CV-240-53 | Silver Express | 0 | Puerto Rico |

| 13-Jul-98 | Ilyushin Il-76MD | ATI Aircompany | 8 | U.A.E. |

| 29-Jul-98 | Embraer EMB-110P1 Bandeirante | Selva Taxi Aéreo | 12 | Brazil |

| 24-Aug-98 | Antonov An-32B | SADELCA Colombia | 0 | Colombia |

| 28-Aug-98 | Dassault Falcon 20C | Reliant Airlines | 0 | USA |

| 8-Feb-99 | Lockheed L-188A Electra | Air Karibu | 7 | D.R. Congo |

| 26-Jul-99 | Ilyushin Il-76TD | Elf Air | 0 | Russia |

| 28-Dec-99 | Cessna 208A Caravan 675 | Seair | 0 | Canada |

| 28-Apr-01 | Cessna 208B Grand Caravan | Les Grands Jorasses | 10 | Argentina |

| 14-Jul-01 | Ilyushin Il-76TD | Russ Air | 10 | Russia |

| 23-Aug-01 | Antonov An-28 | Victoria Air | 4 | D.R. Congo |

| 3-Nov-01 | Cessna F406 Caravan II | GJ Air | 3 | South Africa |

| 12-Jun-02 | Lockheed MC-130H Combat Talon II | USAF | 3 | Afghanistan |

| 17-Jan-04 | Cessna 208B Grand Caravan | Georgian Express | 10 | Canada |

| 4-Dec-04 | Convair CV-340-70 | Miami Air Lease | 0 | USA |

| 15-Mar-05 | Antonov An-26B-100 | ATSA | 0 | Peru |

| 17-Jul-05 | Cessna 525 CitationJet | Hertrich Aviation | 0 | USA |

| 5-Jul-07 | Cessna 208B Grand Caravan | Lancton Taverns Ltd. | 2 | Ireland |

| 19-Dec-08 | BN-2A-20 Islander | Air Vanuatu | 2 | Vanuatu |

| 7-Feb-09 | Embraer EMB-110P1 Bandeirante | Manaus Aerotáxi | 24 | Brazil |

| 15-Nov-09 | Cessna 208B Grand Caravan | Aviation at Work, op.for Air Nave | 3 | Namibia |

| 9-Sep-11 | Cessna 208B Grand Caravan | Susi Air | 2 | Indonesia |

| 3-Jul-13 | Canadair CL-415 | Gov. of Newfoundland and Labrador | 0 | Canada |

| 7-Jul-13 | DHC-3T Texas Turbine Otter | Rediske Air | 10 | USA |

| 19-Aug-13 | Douglas DC-3C | Buffalo Airways | 0 | Canada |

| 2-Jul-14 | Fokker 50 | Skyward International Aviation | 4 | Kenya |

Technical Related Lessons

Safety of flight is dependent on accurately determining the allowable load-carrying capability of cargo restraint systems and their correct application. (Threat Category: Structural Failure)

- Included in the accident airplane's cargo were five mine-resistant ambush-protected (MRAP) vehicles comprised of two 12-ton M-ATVs and three 18-ton Cougars. Investigators determined that the MRAPs were not properly secured, and at least one MRAP, the aft most M-ATV, broke loose from its tie-down restraints. Investigators found that National Airlines manuals were lacking required procedures from both Boeing and the cargo loading manufacturer regarding cargo restraint methods. Despite National's procedures for securing special cargo loads not being followed, the procedures themselves were deficient to the extent that, if followed, they would have resulted in improper loading and restraining of special cargo.

Common Theme Related Lessons

Operators must ensure their weight and balance manuals contain correct procedures to properly load and restrain special cargo. (Common Theme: Organizational Lapses)

- Investigators determined the accident airplane's cargo operations manual omitted required, safety-critical restraint information from the weight and balance manuals of both the airplane manufacturer and main deck cargo handling system manufacturer. The manual also contained incorrect methods for restraining a special cargo load. Specifically, the cargo operations manual did not define the individual tie-down allowable loads for the various components in the cargo system, such as the available seat tracks; did not specify that each tie-down attachment point may be used to react load in only one direction; and did not consider that the full load capability of the attach fittings varied depending on the tie-down strap angle.

FAA oversight must ensure consistency and continuity of operators manuals to include procedures from the airplane manufacturer and cargo handling system manufacturer that specify cargo is properly secured. (Common Theme: Organizational Lapses)

- Procedures in the National Airlines cargo operations manual omitted required, safety-critical restraint information from the weight and balance manuals of both the airplane manufacturer and main deck cargo handling system manufacturer. The operator manuals also contained incorrect methods for restraining special cargo loads. Investigators concluded the FAA did not ensure the National Airlines cargo manual reflected the correct information and guidance that specified how to safely secure the cargo. In addition, investigators determined that FAA inspectors were not equipped with adequate tools and background to ensure proper oversight of an air carrier's procedures for restraining cargo, and that those procedures should be based on airplane manufacturer STC or other FAA-approved data.

Aviation safety is dependent on clear, unambiguous lines of authority as well as properly identified and applied safety criteria. The successful integration of multiple government agencies must be accomplished in a manner that achieves mutually agreed-upon safety goals. (Common Theme: Organizational Lapses)

- For National Airline's Flight 102, the involved U.S. government agencies that were involved included The Department of Transportation (FAA), Department of State, and Department of Defense. The FAA was charged with overseeing safe cargo operations. The Department of State's role included oversight of country-to-country relationships and travel arrangements. The Department of Defense oversaw the contractual obligations of the cargo operation. Lack of proper integration of these multi-level agency roles resulted in confusion and ambiguity of oversight duties.