Grumman Turbo Mallard (G-73T)

Chalk's Ocean Airways

Source: S. Kemper, Bureau of Aircraft Accidents Archives

Miami Beach, Florida

December 19, 2005

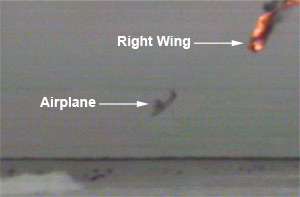

On December 19, 2005, at 1439 eastern standard time, a Grumman Turbo Mallard (G-73T) amphibious airplane, N2969, crashed into a shipping channel adjacent to the Port of Miami, Florida. The accident aircraft was operated by Flying Boat, Inc., doing business as Chalk’s Ocean Airways as Flight 101. The accident occurred shortly after takeoff from the Miami Seaplane Base (X44). Flight 101 was a regularly scheduled passenger flight to Bimini, Bahamas with two flight crewmembers and 18 passengers on board. The right wing separated from the airplane shortly after takeoff. All 20 people onboard the airplane were fatally injured and the airplane was destroyed by impact forces.

Flight 101 was conducted under 14 Code of Federal Regulations (CFR) Part 121 on a visual flight rules flight plan. Visual meteorological conditions prevailed at the time of the accident. Accident investigators determined multiple pre-existing wing fatigue cracks led to a structural failure of the wing.

Source: John Thompson, Airliners.net

History of Flight

On December 19, 2005, Chalk's Ocean Airways Flight 101, N2969, departed at 1305 from Fort Lauderdale/Hollywood International Airport, arriving at the Miami Watson Island Seaplane Base (X44) at 1321. At 1439, bound for Bimini, Bahamas, the airplane departed X44 and crashed into a shipping channel adjacent to the Port of Miami about one minute after takeoff. Witnesses reported that the airplane’s right wing separated from the rest of the airplane. Many noted that smoke or fire came from the wing before it descended into the water. About half of the witnesses reported hearing an explosion associated with the wing separation.

Source: NTSB

Lifeguards were the first to arrive at the accident location and the Miami Coast Guard was on scene within approximately 15 minutes. Most of the wreckage was in 30 feet of water. The two flight crewmembers and all 18 passengers, which included three lap-held infants, suffered fatal injuries.

Two days prior, the accident captain and another pilot flew the accident airplane for ten segments. According to investigators, this other pilot stated that he and the accident captain had conducted a 15- to 20-minute operational check flight prior to passenger service. The pilot stated that the airplane had recently undergone maintenance before these short hauls. He reported that there were no unusual vibrations and he did not observe fuel, oil, or hydraulic fluid leaks.

Source: NTSB

Chalk's Operations

At the time of the accident, Chalk's Ocean Airways was a seaplane operator certificated under 14 CFR Part 121 and flew several Grumman Mallard high-wing, flying-boat airplanes that were originally manufactured in the post-World War II era. The company conducted regular, short-haul flights between the Bahamas and the U.S., often flying ten or more segments on a single aircraft each day. At the time of the accident, the airline claimed to be the oldest continuously operating airline in the world, having begun operations in 1917.

Chalk's Grumman Turbo Mallards

Source: NTSB

The Grumman Mallard was in production between 1946 and 1951, with 59 aircraft manufactured. The original piston-powered Mallard was certificated in 1943 with requirements that were amended in 1944 and included a static strength analysis using loads that do not vary with time. No requirements for a fatigue analysis nor damage tolerance analysis existed at the time the G-73 was originally certificated. Fatigue analysis became a requirement in the 1950s and damage tolerance became a requirement in the 1970s.

The accident aircraft was built in 1947 and Chalk's purchased it in 1980. In the early 1980s, Chalk's modified three of their airplanes by replacing the two radial piston engines with two Pratt & Whitney PT6A034 turbo-prop engines. This modification made them turbine-conversion amphibious airplanes in accordance with an FAA-approved supplemental type certificate (STC) SA2323WE, which included an increase in gross weight from 12,750 to 14,000 pounds and provided more horsepower at altitude. Further enhancements, modified in accordance with STC SA4410SW, changed the airplanes interior arrangements from ten passengers to a 17-seat passenger configuration.

While a regulation for changes requiring a new type certificate was in effect since 1965 for airplanes undergoing propulsion engine transitions, the FAA granted the airline the option to use the airplane’s original type certificate. It was not possible for an STC applicant to accomplish a full airplane type certificate program and to have access to the original equipment manufacturer (OEM) data. Therefore, the applicant would not be able to complete a recertification of the aircraft. Not requiring a new type certificate was believed by regulators to be appropriate as the airplane would benefit from enhanced propulsion performance and increased reliability of the turbine engine. As a result, the accident airplane was not subject to the same fatigue evaluation criteria as many airplanes during this time.

Chalk's Maintenance Department

The Chalk's general manager oversaw the maintenance department. The director of maintenance and the chief inspector/director of quality control reported to the general manager. At the time of the accident, Chalk's employed 82 people, including ten pilots, 12 mechanics, and five mechanic assistants. Chalk's did not have an engineering department to oversee structural airplane issues.

They contracted major repairs of the airplane's structure to FAA designated engineering representatives (DERs). Chalk's FAA principal maintenance inspector (PMI) conducted an inspection and records review on October 7, 2005, two months before the accident.

Wing Structure

Source: Air Zoo Aerospace & Science Museum

Source: Air Zoo Aerospace & Science Museum

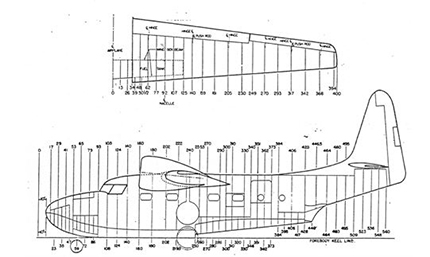

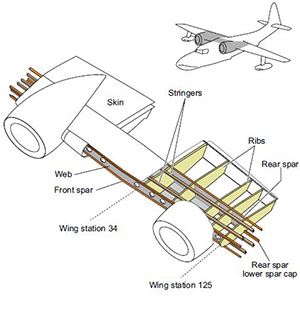

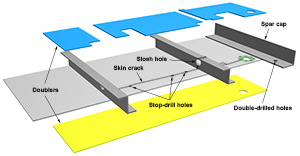

The G-73T wing structure includes a center wing box joining the outer wing sections. The center wing box spans from left wing station (WS) 125 to right WS 125. Outboard of WS 125 are the outer wing sections.

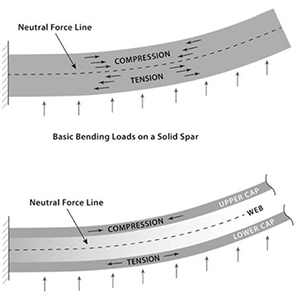

The structural components of the wing box include the front spar, rear spar, stringers, ribs, upper skin, and lower skin. Spars, the main structural members of the wing, are beam-like components consisting of upper and lower caps attached by a web. Stringers are span-wise members that are attached to the upper and lower wing skins and share loads with the skins.

Ribs are structural components of the wing that are oriented forward and aft, giving the wing its cambered shape and serving other structural purposes. The skin is made of metal panels that form the upper and lower surfaces of the wing. The vertical surface of each Z stringer, called a web, has two slosh holes located just outboard of the wing ribs at WS 34 and WS 48. The purpose of the slosh holes is to allow fore and aft fuel flow in the wing tank due to changes in airplane pitch attitude.

Structure Aging and Failure Overview

Chalk's aging G-73Ts were used in a corrosive, saltwater environment for short-haul flights, which required frequent and ongoing inspections and maintenance. This environment included various stressors that impacted the accident airplane. The following explains these concepts including flight cycles, aging airplane, redistribution of airplane internal loads, and ineffective maintenance and repairs.

Source: Paul Dye, kitplanes.com

View Larger

Flight Cycles

At the time of the accident, the airplane had accumulated 31,226 total flight hours and 39,743 flight cycles (takeoff-fly-land, often referred to as a ground-air-ground or GaG cycle). In an airplane fatigue analysis, flight hours and cycles are the most common measures used to define an aging airplane.

Chalk's operated its fleet mostly for short-haul flights from Florida to various islands near the Atlantic coast. Short-haul flights result in more flights per day, thus more flight cycles. Flight cycles contribute to wing fatigue damage. This is because a flight cycle consists of wing-down bending before flight, followed by wing-up bending during flight, and ends with wing-down bending after flight.

Aging Airplane

Because the Grumman Mallard was manufactured in the 1940s, it was quite old and subject to the FAA's "Aging Airplane Inspections and Records Reviews." At the time of the accident and at the writing of the accident report, the regulation was numbered as 14 CFR 121.368, which has since been repurposed for "Contract Maintenance." The aging airplane regulation is now numbered 14 CFR 121.1105, but this was not yet effective at the time of the accident. The purpose of this regulation was for the operator to demonstrate to the FAA that "the maintenance of age-sensitive parts and components of the airplane has been adequate and timely enough to ensure the highest degree of safety."

The operations specifications for Chalk's indicated that an aging aircraft inspection and records review was required. While the interim and actual final drafts for this rule were silent with respect to Grumman Mallard or Turbo Mallard aircraft, the NTSB accident report indicated that the Chalk's operations specifications did include a records review for their operating certificate. According to the report, Chalk's PMI conducted this review two months prior to the accident. The review:

- Did not include the doubler repair that was observed on the chordwise skin crack just outboard of right WS 34 and for which Chalk's did not have records (the area of the wing that failed catastrophically)

- Included the major repair conducted on April 13, 1992 to the rear spar upper spar cap at right WS 34

- Included the May 6, 1992 major repair to the lower wing skin at left WS 34

- Found that no further action was required for these repairs

Internal Load Redistribution

As designed, there is an internal loads distribution in any airplane structure. If a local structural failure exists, there is a load redistribution to adjacent structural elements. The airplane remains capable of flying until the redistributed internal loads cannot be supported by the remaining structure, leading to a catastrophic failure.

According to investigators, Chalk's inspection programs did not identify the failed structural details. Their maintenance program focused primarily on repairing ongoing fuel leaks, but they did not address the root cause failures (stringers, skin cracks, aft spar cracks) that led to this accident. Performing effective repairs on the failed structural parts could have prevented catastrophic failure of the wing structure.

Treatments and Repairs

Maintenance and inspection programs are a vital means to reduce the effects of aircraft aging and to prevent failure. These programs help ensure operational safety through problem detection, effective treatments, and validated assurance of proper repairs.

Repairs to an aircraft may treat just a symptom, for example a fuel leak, but not address the source of the issue. When the underlying cause goes unaddressed, the airplane may not meet the level of safety intended by airworthiness standards.

With Chalk’s small fleet of airplanes, if an airplane was out of service for days or weeks, there was a dramatic effect on the airline’s revenue. Investigators noted that this led to pressure on maintenance personnel for the airplanes to be repaired expediently, resulting in insufficient repairs that did not address underlying problems. The extent of repetitive maintenance actions should have been red flags of larger, systemic concerns.

For example, ongoing fuel leaks were addressed by reapplying sealant, and fatigue cracks were repeatedly repaired by stop drilling the tip of the crack (to help prevent further crack growth). With DER analysis and approval, stop drilling of small cracks may, in some limited situations, serve as a temporary solution. While possibly effective in the short term, stop drilling cracks does not address the long-term airworthiness issue. On the accident aircraft, when the fatigue cracks were not properly repaired, investigators concluded they continued to grow and spread to other locations. Thus, the repairs did not restore the internal load paths and the structural elements became overloaded and failed.

Additionally, investigators noted that company records of repairs were sometimes incomplete or missing. The lack of complete records made it harder to understand and identify underlying structural deficiencies.

This animation further describes these concepts and how they impacted the accident aircraft.

Break-up Sequence

Source: NTSB

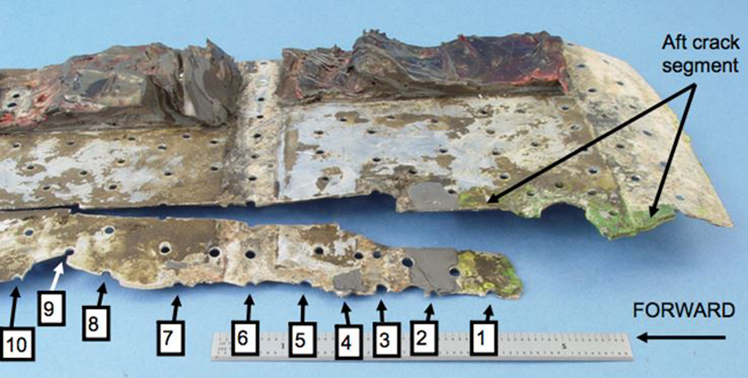

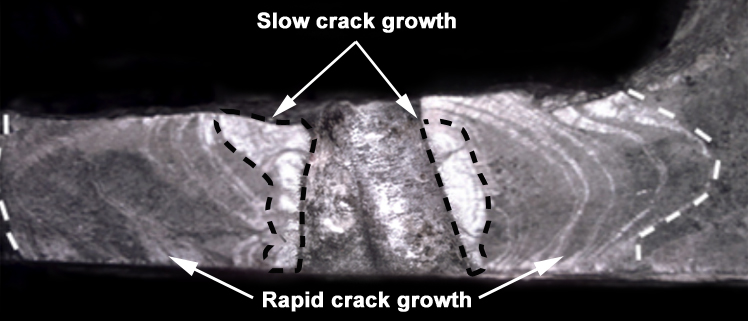

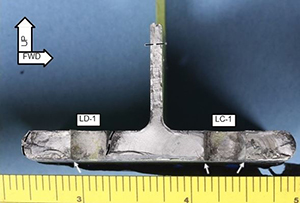

Post-crash examination of the fracture surfaces of the failed structural elements of right WS 34 enabled a likely failure scenario that separated the right wing from the airplane. Details to note on the WS 34 fracture location include: (1) the right rear Z stringer; (2) the lower wing skin; and (3) the right rear lower spar cap, which carries a major fraction of the airplane flight loads.

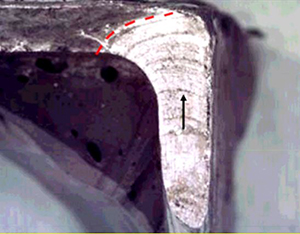

According to investigators, the right rear Z stringer likely had the oldest fatigue crack, and it may have existed several years before the accident. This crack began from a slosh hole near and outboard of right WS 34. The slosh hole created a stress concentration. Wing-bending loads are highest near the wing root, and fatigue cracking is more likely in areas of higher stress. Thus, investigators concluded the cyclic flight loads caused the crack to initiate and grow in this high-stress location.

Source: NTSB

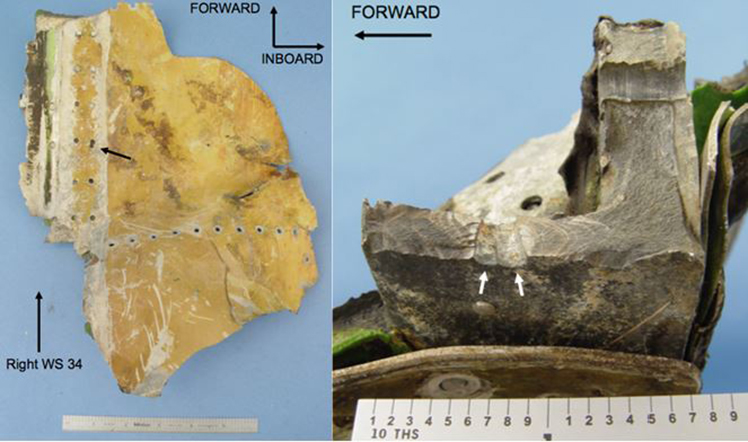

Investigators concluded that the second structural failure was the growth of the chordwise fatigue crack of the wing skin following the fracture of the right rear Z stringer. Fracture of the stringer resulted in the loads being transferred to the skin. This load transfer led to accelerated growth of the skin crack. The addition of external doublers over the skin crack made visual detection of the crack impossible as it was now hidden between the doublers.

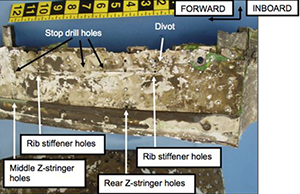

Additionally, it was determined that several fatigue cracks likely linked together, creating the 16-inch-long fatigue crack at this location. Investigators concluded that this structural issue probably existed over a period of months or years prior to the wing separating from the airplane. Evidence of this includes several stop-drill holes found in the crack path towards the rear of the wing lower panel. The NTSB also noted several ineffective attempts at repairs in this area.

Source: NTSB

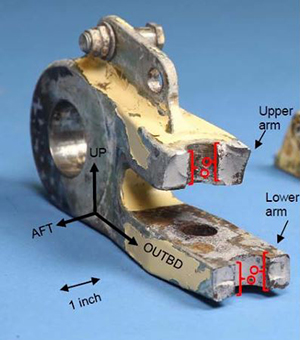

The combination of the failed Z stringer and lower skins caused additional load to be carried by the right wing’s rear lower spar cap. Because a significant portion of flight loads are carried by the rear spar, transfer of loads here contributed significantly to spar cap crack growth. A double-drilled hole (also known as a figure-8 hole) in the web of the spar cap acted as a stress concentration which became a crack initiation site.

Photo of rear spar lower cap fracture with a double-drilled hole. (right)

Source: NTSB

Besides the double-drilled holes, several cracks from sites in the lower right rear spar cap contributed to the relatively rapid failure (fracture) in the vicinity of WS 34. Fracture occurs when the residual strength degrades below what is needed for flight. In contrast to the long duration of slow crack growth in the Z stringer and lower wing skin described previously; fracture surface examination of the rear spar lower cap detected flight-by-flight rapid crack growth. This cracking aft of the hole propagated from a length of 0.07 to 0.44 inches rapidly in 11 increments, each one likely associated with an individual flight cycle.

Source: NTSB

Source: NTSB

This illustration summarizes the progressive issues that eventually led to wing separation. These failure locations included the fractured stringer with the slosh hole cracks, the wing skin cracks that were treated with stop-drill holes and covered by doublers, and the overloaded rear spar cap that underwent several improper repairs such as double-drilled holes.

Wreckage Examination

Much of the aircraft wreckage was contained within a debris field of about 200 feet by 200 feet and submerged in about 30 feet of water near a rock jetty. The fuselage, landing gear, and empennage, along with the left wing and engine, were found in the main debris field. The separated right wing, with the right engine still attached, was located approximately 160 feet away. Investigators noted that the center wing box structures were fractured where the wing intersected the fuselage at right WS 34, the location of the right-wing separation.

Source: NTSB

Post-crash examination of the wreckage revealed that there were multiple poor fatigue details in the repairs of old fatigue cracks, some of which led to new crack initiation sites in the region of the catastrophic failure of the wing. These deficient repair details included unfilled holes, poorly drilled holes, double-drilled holes, under/over driven rivets, short fastener edge distance, sanding and grinding marks, and leaving a long, stop-drilled skin crack. Investigators also found instances of wing structure corrosion damage as well as poorly executed repairs on previously detected internal wing structure corrosion sites.

Photo of example installed rivets. These include an under-driven rivet (left), a properly installed rivet (middle) and an over-driven rivet (right).

Source: John Stoll

There was no evidence from either airplane performance concerns nor visual cues on the airplane that would have provided a warning to the flight crew of the right wing’s imminent failure. A pre-flight walk-around inspection would not have revealed the long skin crack because it was hidden by the external doubler. The only possible way to see the skin crack would have been to use non-destructive inspection (NDI) techniques.

Fuel Leaks from Cracked Structure

Chalk's Ocean Airways used flight logs and routine/non-routine work cards to record maintenance of the airplanes. They also used numbered flight logs to record the flights and the airplane's non-routine maintenance each flight day. However, during the investigation, the NTSB noted missing maintenance records, discrepancies in records, and undocumented repairs. The NTSB also had serious concerns involving ongoing fuel leaks on the accident airplane.

According to the accident report, many of the flight logs documented numerous fuel leaks. Meeting minutes from a maintenance Continuing Analysis and Surveillance System (CASS) meeting, just months before the accident, showed six fuel leaks near the fuel tank on either the right or left wings in a five-day period. Just prior to the accident, meeting minutes also reflected a fuel leak into the right-wing dry bay for three consecutive days.

Chalk's was required to monitor airplane performance through data collection and analysis. However, investigators determined their evaluation process was inadequate and failed to recognize the ongoing leaks as indicators that there could be, and was, serious structural damage inside the wing.

The NTSB also noted that repair methods Chalk's used to resolve the fuel leaks, which involved removing and replacing sealant, were ineffective because fuel leaks continued to be an issue. Investigators believed that Chalk's should have used a more effective repair method and they should have detected the structural damage to the right wing. They concluded that correction of the structural damage would have stopped the leaks and might have prevented the accident.

Source: John Stoll

Most modern transport airplanes use the wing structure for the fuel tank, known as an integrated fuel tank. Since the wing structure is assembled from multiple pieces (wing skin, spar caps, etc.), where the pieces are joined, sealant must be applied to prevent fuel from seeping through the contact areas. Sealant can degrade and sometimes its failure can cause a fuel leak. In those cases, replacing the sealant is the only restorative action that needs to be performed.

However, in the case of the accident airplane, the leaks were not due to degraded sealant; the fuel was leaking through cracks in the critical wing structure. Having to repeatedly reapply sealant for this repair was indicative that this was more than a sealant problem and investigators noted that mechanics should have conducted further inspection to find the source of the leak.

Ineffective Repairs

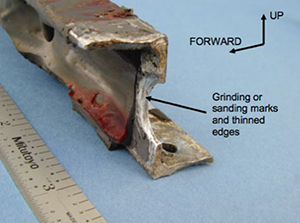

Source: NTSB

To ensure aviation safety, it is not just how well an airplane is designed and manufactured, it is also how the airplane is operated and maintained. The purpose of the maintenance program is to preserve the “as designed and manufactured” airworthiness. On the accident airplane, ineffective repairs at or near WS 34, where the wing separated, included:

- Sanding marks as an attempt to remove cracks at the Z stringer slosh holes, which did not entirely remove the crack, thus allowing the crack to grow larger

- Covering of a lower flange of the rear Z stringer by an internal doubler as an ineffective attempt to reinforce the fractured Z stringer

- Multiple-site fatigue damage locations that linked in the area of the rear Z stringer, indicating repairs did not restore the component

- Fasteners inserted through sealant instead of the lower skin, resulting in ineffective load transfer

- Three stop-drill holes that showed Chalk's had detected the skin crack numerous times before they applied the doublers, which was indicative of an underlying structural problem that Chalk's did not properly address

Source: NTSB

Even when repaired with doublers, leaving a stop-drilled crack in the skin may cause the crack to continue to propagate. The doublers do not remove all the load that is being reacted by the skin. The load that remained in the skin must go around the stop-drilled crack, resulting in a large stress concentration at the stop-drill hole.

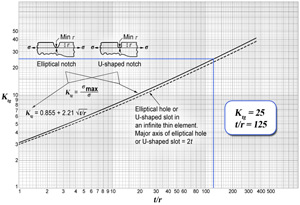

Stop-Drill Crack Treatment

The crack in the skin of the accident airplane was nearly 16 inches long and the stop drills appeared to be the commonly used quarter-inch diameter. A crack that is stop drilled can be modeled as a U-shaped notch to determine the stress concentration. Peterson’s Stress Concentration Factors book, an industry standard, has a solution for the stress concentration of a U-shaped notch in a semi-infinite thin plate. For the accident airplane, and applying Peterson’s model, t/r ~ = 15.5/ (0.25/2) = 125 on the x axis. This yields a stress concentration factor of 25 on the y axis. A stress concentration of this magnitude would result in the crack reforming.

Source: Peterson’s Stress Concentration Factors, Third Edition

Using a stop drill in primary structure does not guarantee that the crack will no longer grow. The correct way to repair such a crack is to cut out the skin containing the crack using large radius corners and splicing in a new piece of skin.

If repairs are poorly designed and constructed, such as the example stress concentration of this large stop-drilled crack, they can fail so rapidly that a normal internal inspection cycle is not frequent enough to discover the damage before catastrophic failure.

NTSB Repairs Review

The NTSB’s review of FAA records for the accident airplane indicated the following regarding major repairs and alterations of the wing:

- Chalk's made a major repair to the rear spar upper spar cap at right WS 34 in 1992 due to structural corrosion under the skin and popped rivets that were discovered on the right wing at WS 34. When they removed the skin, they also found light-to-moderate corrosion on the top aft spar.

- Chalk's also made a major repair to the rear Z stringer at right WS 50.5 in 2000. However, the company could not provide the NTSB with corresponding maintenance records nor a description of the discrepancy that resulted in the repair. When investigators inspected the wreckage, they observed that rivets used in that repair were not installed in accordance with AC 43.13-1B, 4-57 Riveting, "Riveting Practice and Rivet Imperfections." Some of the rivets Chalk's installed had undersized shop heads, were overdriven, and one rivet through the skin and stringer flange at the slosh hole was of a larger size and different head type than specified for use.

- Investigators also noticed another major repair that Chalk's mechanics made to the lower right-wing skin at the location where the wing separated. Chalk's maintenance records did not contain an entry for this major repair, which included one external and three internal doublers that were applied over a long, chordwise skin crack outboard of right WS 34.

- Repairs to the right and left WS 34 locations showed additional evidence that the rivet installation for each was not in accordance with AC 43.13-1B, 4-57 Riveting, "Rivet Edge Distance," "Rivet Hole Spacing for Single-Lap Sheet Splices," and "Riveting Practice and Rivet Imperfections and Holes." Specifically, fastener holes were at edge distances less than specified, rivet-hole spacing was less than specified, and some holes did not meet specifications because they were double drilled.

Fleet Issues

Source: NTSB

Operator maintenance issues were not confined to the accident airplane. Another G-73T underwent major repairs just months before the accident to fix the lower, right-wing skin due to fuel leaks from the right wing-to-body fairing. The FAA DER found that fuel was leaking from a 22-inch crack in the lower skin. The crack was covered by the fairing and reduced the load-carrying capacity of the right-wing box by approximately 50 percent.

According to investigators, the fuel leak issue and stringer damage should have prompted Chalk’s to perform a comprehensive inspection of the entire fleet’s wing structures. Previous issues on this sister airplane also included: multiple stringers that were corroded and cracked; a 17-inch crack on a left-wing skin doubler; prior repairs to the fuel sump drain due to corrosion that included a 14-inch crack; and evidence of grinding and corrosion on other parts of the airplane wing structure. In another instance, no regard was given for fastener spacing or for net section, the structural material that remained after the incorrect drilling of holes.

Financial Viability and Oversight

When an airline is financially distressed, there is a concern that the company may make operations and maintenance decisions that are focused on cost-cutting measures at the expense of operational safety. When this occurs, the FAA, through its Safety Assurance System, deems it necessary to increase oversight scrutiny to ensure fleet airworthiness.

As a result of this accident, the NTSB determined that proper regulatory oversight was not provided. In a research report dated January 2, 2008 entitled "Oversight of Air Carriers Experiencing Financial Difficulty," the NTSB expressed its concern that, "The FAA received cues from a number of sources that, when looked at in aggregate, served as indicators of potential safety deficiencies at Chalk's Ocean Airways." However, the NTSB noted that the FAA principal operations inspectors (POI) did not express operational or maintenance concerns and did not modify Chalk's surveillance program. Specific examples cited by the NTSB included:

- Changes in support staff positions

- Shifts in contractors or contractual arrangements

- Noticeable turnover of personnel and labor unrest

- Non-payment of debts

- A showing by CASS that there is a rising trend in performance, inspection, and maintenance deficiencies

Conclusion

The NTSB determined that the right wing separated from the accident airplane at WS 34 at the intersection of the fuselage because of pre-existing fatigue fractures and cracks. This pre-existing damage was in the rear Z stringer, lower skin, and rear lower spar cap. This multiple-element fatigue damage reduced the residual strength of the wing structure and caused the failure of the wing during normal flight operations. The airplane crashed immediately after the separation of the wing.

Major issues stemming from airline management, the maintenance department, and FAA oversight were identified by the NTSB and contributed to this accident.

- Company management – Areas of weakness included financial solvency, employee morale issues; increasing pilot turnover; and ineffective maintenance and inspection oversight that lacked a quality safety culture.

- Maintenance department – Numerous maintenance practices were deficient, such as improper repair design and implementation; insufficient inspections; and incomplete records management.

- FAA oversight – While the FAA had published guidance for their POI regarding recognition and oversight of financially distressed airlines, the NTSB concluded that the assigned POI did not apply this guidance nor increase safety scrutiny and surveillance even though the POI recognized some concerning issues.

The National Transportation Safety Board determined that the probable cause of this accident was "the in-flight failure and separation of the right wing during normal flight, which resulted from (1) the failure of the Chalk’s Ocean Airways maintenance program to identify and properly repair fatigue cracks in the right wing and (2) the failure of the Federal Aviation Administration to detect and correct deficiencies in the company's maintenance program."

Complete list of accident report findings: NTSB Findings

Complete accident report: Chalk’s Accident Report

Safety recommendations to the FAA:

New Recommendations

- Verify that the maintenance programs of commercial airplane operators include stringent criteria to address recurring or systemic discrepancies to include, if necessary, further analysis of the discrepancies through a comprehensive engineering evaluation.

- Identify the systemic deficiencies in the maintenance program oversight procedures that led to this accident and modify those procedures to ensure that the maintenance program plans for commercial operators are adequate to ensure the continued airworthiness, both structural and otherwise, of the operator's fleet.

Previously Issued Recommendation Reiterated and Classified in This Report

- Include the Continuing Analysis and Surveillance System guidance from Advisory Circular (AC) 120-16D, "Continuing Airworthiness Maintenance Programs," and AC 120-79, "Developing and Implementing a Continuing Analysis [and] Surveillance System," in Federal Aviation Administration Order 8300.10, Airworthiness Inspector's Handbook.

Previously Issued Recommendation Resulting from This Accident Investigation

- Require records reviews, aging airplane inspections, and supplemental inspections for all airplanes operated under 14 Code of Federal Regulations (CFR) Part 121, all U.S.-registered airplanes operated under 14 CFR Part 129, and all airplanes used in scheduled operations under 14 CFR Part 135. This would include those airplanes operated under 14 CFR Part 135 that carry nine or fewer passengers and those that are operated in scheduled cargo service.

Applicable CFRs

14 CFR 21.19, "Changes Requiring a New Type Certificate," This regulation, which had been in effect since February 1965, describes the circumstances in which an applicant for type certification of a changed product must apply for a new type certificate. However, in certain circumstances the FAA allows for an applicant to apply former regulations instead of new regulations. The practice is known as “grandfathering.” In the 1960s, STCs to change reciprocating piston engines to turboprop engines were commonplace, as was the ability to remain grandfathered to the original type certificate. In the case of Chalk’s, Frakes Aviation was grandfathered, allowing the airline to use the airplane’s original type certificate (which was issued in September 1947) as the basis for the analysis required for the 1981 STC for installation of the engines on the airplane.

View the STC issued to Frakes Aviation for the accident airplane here: Applicable engine modifications STC

14 CFR 121.368 "Aging Airplane Inspections and Records Reviews." The purpose of the regulation is for the operator to demonstrate to the FAA that "the maintenance of age-sensitive parts and components of the airplane has been adequate and timely enough to ensure the highest degree of safety."

14 CFR 121.370a, "Supplemental Inspections." The G-73T airplane was not required to undergo these supplemental inspections because the applicability statement of the final rule excluded aircraft with less than 30 seats.

14 CFR 121.373, "Continuing Analysis and Surveillance." Each certificate holder is required to establish and maintain a system for the continuing analysis and surveillance of the performance and effectiveness of its inspection program. This includes maintenance, preventative maintenance, and alterations as well as the correction of any deficiency in those programs, regardless of whether those programs are carried out by the certificate holder or by another person.

FAA Advisory Circulars

Advisory Circular 43.13-1B, "Acceptable Methods, Techniques, and Practices - Airplane Inspection and Repair." This AC contains methods, techniques, and practices acceptable for the inspection and repair of non-pressurized areas of civil airplanes, only when there are no manufacturer repair or maintenance instructions. This data generally pertains to minor repairs. The repairs identified in this AC may only be used as a basis for FAA approval for major repairs, absent either manufacturer's service instructions in accordance with 14 CFR 43.13(a) or in accordance with engineering data prepared by an authorized representative of the FAA.

Advisory Circular 120-16D, "Continuing Airworthiness Maintenance Programs." This AC applies to each person employed or used by an air carrier for any maintenance, preventive maintenance, or alteration of its airplane and is intended to describe the nine elements that comprise air carrier maintenance programs and what should be included in an air carrier maintenance program.

Advisory Circular 120-79, "Developing and Implementing a Continuing Analysis and Surveillance System." This AC provides information on how to implement a CASS, which is required for certain types of air carriers and commercial operators under 14 CFR 121.373 and 135.431. A CASS is a quality management system for air carriers and commercial operators that monitors and analyzes the performance and effectiveness of inspection and maintenance programs.

Grumman Customer Bulletins

Grumman Model G-73 Mallard Customer Bulletin 89, "Re-sealing of Mallard Integral Fuel Tanks." This bulletin, issued on May 28, 1963, notes the potential for corrosion. Corrosion is likely if these conditions are present: chronic leakage of fuel; looseness of sealant in the tank; and blisters, swelling, or visible corrosion in the skin in the tank areas.

Grumman Model G-73 Mallard Customer Bulletin 90, "Inspection of Mallard Wings – Bladder Type Fuel Cells." This bulletin, issued on July 24, 1964, advises owners to inspect for possible corrosion of the lower wing skin in the tank areas. The location of inspection contains important structural members running spanwise in the wing.

Chalk’s Ocean Airways, through use of seaplanes, was a popular airline used by locals, tourists, and celebrities making their way from Florida to the Bahamas. Founded in 1917 as Red Arrow Flying Services, the airline was temporarily closed during World War I then opened its doors again in 1919 as Chalk’s Ocean Airways. The airline later closed during World War II and donated its airplanes to the Civil Air Patrol where that fleet performed hundreds of anti-submarine missions.

In 1974, Resorts International, the owner of several hotels and resorts in the Bahamas, acquired the airline. The company partnered with Frakes Aviation to upgrade the fleet of Grumman Mallards from piston engines to turboprop engines. In 1985 they also converted five ex-military Grumman Albatrosses to passenger service. In 1991 the owners sold Chalk’s to United Capital Corporation.

Chalk's experienced its first fatal accident in March 1994 when one of its seaplanes crashed upon take-off from the Florida Keys. Two crewmembers were killed. Several more sales of the airline occurred through the 1990s, at one time operating as Pan Am Air Bridge, which experienced an involuntary bankruptcy in 1999. An entrepreneur and former Eastern Airlines pilot acquired the airline out of bankruptcy and rebranded the company back to the Chalk’s name. By this time, the airline had only two leased Grumman Mallards and 35 staff members.

The new owner brought in more Mallards and an Albatross to the fleet. About five years into operations, Chalk’s experienced this inflight wing separation accident and the Department of Transportation's Air Carrier Fitness Division suspended Chalk’s Ocean Airways' economic authority to operate because of maintenance concerns. While the company intended to return to operations in late 2006, their Bahamian air certificate had expired. After the NTSB’s final accident report was issued in 2007, the FAA revoked Chalk’s air operator’s certificate on September 30, 2007.

During the final years of operation, the company experienced issues regarding recurring discrepancies, inadequate maintenance practices, a decrease in morale, and human resource complaints and resignations. Much of the concern stemmed from flight crew apprehension about inadequate maintenance practices, including an in-flight upset due to a severed flight control cable, two inflight engine losses, and then the fatal airplane crash. Until this time, Chalk’s Ocean Airways held the record as the oldest continuously operating airline in the world.

Per the NTSB report and related docket, the following are some of the major safety issues facing the airline prior to the accident:

- Improper structural repair design – The design of the wing repairs on the accident airplane had poor fatigue details, did not fully restore static strength, and did not provide any periodic non-destructive test inspections that were needed since new cracks would be hidden by the repair doublers.

- Inadequate maintenance practices – Investigators determined that pilots often had to record fuel leaks and other issues numerous times before repairs were made. Once Chalk’s did complete the maintenance, repairs were sometimes faulty and maintenance personnel used incorrect parts and techniques. The staff often addressed only the symptoms and not the underlying cause.

- Poor and incomplete records management and insufficient inspections – The NTSB found that major repairs to the company’s airplanes were undocumented in Chalk’s maintenance records. Some of these included repairs to WS 34, which was the location of the wing separation of the accident aircraft. For areas not externally visible, Chalk's did not perform proper repairs of the airplane components. Review of maintenance processes by the PMI did not uncover this practice.

- Pilot concerns

- Maintenance concerns - One year prior to the accident, a company airplane experienced an in-flight event when an elevator cable broke during climb-out. Following this event, all pilots and dispatchers met to voice concerns about maintenance. Three of the company's six captains resigned from the airline, and then two flight crew members later died because of this accident.

- Decreased morale - Morale at Chalk's was considered low, mainly due to maintenance concerns by the pilots. Investigators noted that pilots raised concerns that mechanics would sign off that an airplane was fixed when it was not. As one pilot stated, "There was a widespread perception that pilot complaints were not properly addressed by maintenance, and that it was often necessary to write up the same problem repeatedly until it was fixed. The pilots wanted the airplanes fixed and were willing to see the company close if the issues were not addressed."

- Lack of financial solvency – The airline had monetary issues that the NTSB believed put them at risk for safe maintenance and operations. For example, as the airplanes were manufactured in the 1940s, ongoing maintenance was costly, and spares were difficult to obtain.

- Lack of sufficient FAA oversight – The operator failed to provide adequate maintenance and inspection oversight and lacked a quality safety culture. FAA surveillance did not challenge the insufficient practices, and the FAA PMI did not act on repeated indicators of problems with the accident airplane. The PMI was supposed to verify that maintenance programs included stringent criteria to address recurring or systemic discrepancies.

Maintenance practices employ repair techniques that do not jeopardize airworthiness.

- The NTSB noted numerous inadequate maintenance practices and poor repairs that did not restore the structural capability of the accident aircraft.

- The NTSB found that Chalk's maintenance and repair processes were ineffective, poorly documented, and contained recurring discrepancies.

Pilot concerns regarding airplane issues are addressed to ensure aviation safety.

- Chalk's pilots often had to record fuel leaks and other problems multiple times in the maintenance log for maintenance to take corrective action.

- Several Chalk's pilots found the maintenance process to be so flawed that they resigned from the company.

Regulatory and industry safety oversight organizations are effective and ensure that operations and maintenance practices maintain airplane airworthiness.

- The managers of Chalk's safety organization were not proactive in ensuring that their maintenance operations were effective. Processes lacked complete records management and did not properly or fully address ongoing airplane maintenance and repair issues.

- Investigators noted that Chalk's was a financially distressed carrier. As a result, additional FAA scrutiny was necessitated to ensure safe operations but did not occur.

There were several events and indicators that Chalk's maintenance practices were insufficient. Had these issues been properly addressed, this accident may have been prevented. Examples include:

- A fuel leak on the accident aircraft that took 10-15 requests by the pilots before Chalk’s conducted repairs.

- Discovery of a 22-inch crack in the right-wing lower skin of another fleet aircraft just months preceding the accident. This crack reduced the load-carrying capacity of the right-wing box by about 50 percent.

- Three of six captains left the company within a year prior to accident due to maintenance concerns.

- FAA oversight was lacking for both ongoing maintenance concerns as well as increased surveillance needed due to Chalk’s being considered a financially distressed carrier.

Japan Airlines Flight 123, Gunma Prefecture, Japan, August 12, 1985

Source: Aircraft Accident Investigation Commission

A Boeing 747SR was a scheduled domestic passenger flight from Tokyo’s Haneda Airport to Osaka International Airport, Japan. The aircraft suffered a sudden decompression twelve minutes into flight and crashed. Investigators determined that rapid decompression was caused by a faulty repair by technicians after a tail strike incident during a landing in 1978.

It was discovered that certain rows of rivets on the newly replaced lower half of the bulkhead had inadequate edge margins. A solution was engineered and involved installation of a splice plate to join the upper and lower halves of the bulkhead. This rework design called for a single splice plate to be used to provide a continuous load path between the upper and lower halves of the bulkhead. The splice plate was difficult to install, owing to the compound curvature of the splice plate and adjoining structure. The eventual solution, which was a departure from the installation instructions, involved cutting the splice plate into two pieces and fitting the pieces in place individually. This deviation from the approved repair resulted in a single row of rivets transferring the load to the upper affected web plate instead of the two rows specified in the repair instruction drawing. This deviation resulted in the bulkhead web being improperly loaded and susceptible to early fatigue.

Cabin pressurization continued to expand and contract the improperly repaired bulkhead until the day of the accident, when the faulty repair failed, which caused a rapid decompression. A large portion of the tail then ripped off and caused the loss of hydraulic controls to the airplane. Casualties of the crash included all 15 crew members and 509 passengers.

Accident module: Japan Airlines Flight 123

Aloha Airlines Flight 243, Maui, Hawaii, April 28, 1988

Source: NTSB

A Boeing 737-200 leveled at flight level 240 on an inter-island flight from Hilo to Honolulu when an 18-foot-long section of the upper fuselage suddenly departed the airplane. The airplane had accumulated 89,680 flight-cycles and 35,496 flight-hours at the time of the accident. The NTSB determined that the probable cause of the accident was the failure of the maintenance program to detect the presence of significant dis-bonding and fatigue damage which ultimately led to the failure of the lap joint at stringer S-10L and the separation of the fuselage upper lobe. It was assumed that as the structure fatigued, a rupturing fuselage skin crack would be arrested at stiffeners/tear-straps, allowing the skin to flap, and resulting in a safe decompression. The depressurization with flapping skin was considered "obvious damage," removing the need for directed inspections to find cracks. In fact, multiple small cracks went undiscovered for a sufficient period to allow linking of cracks, resulting in catastrophic failure.

Accident module: Aloha Airlines Flight 243

Department of Transportation Action – In December 2005, immediately after the accident, the DOT's Air Carrier Fitness Division suspended Chalk’s Ocean Airways' economic authority to operate under the Flying Boat, Inc. Part 121 air operator’s certificate. The DOT stated that the air carrier had one year to "prove to [the DOT] that the public interest is best served if they [Chalk's Ocean Airways] re-start their operation." As of the one-year target date, Chalk's Ocean Airways was not operating its own airplanes; thus, the Part 121 certificate remained suspended and the company entered a wet lease arrangement with another certificated carrier to provide transportation. Flying Boat, Inc. retained its Part 145 repair station authorization for Chalk's Ocean Airways; however, according to an FAA inspection on December 14, 2006, that organization had little activity. After the final accident report was issued in 2007, the FAA revoked Chalk's air operator's certificate.

Special Airworthiness Information Bulletin (SAIB) NM-06-18 – The FAA issued this SAIB on December 23, 2005, advising operators who owned G-73 and G-73T aircraft of the accident circumstances and pending investigation. The SAIB stated, in part: "The FAA is considering the need for mandatory detailed inspections of parts or all of the wing structure on the fleet of G-73 airplanes. If the FAA determines that the accident airplane wing's pre-separation condition is potentially manifest in other G-73 airplanes, the FAA will take appropriate action."

NTSB Research Report, "Oversight of Air Carriers Experiencing Financial Difficulty" – The NTSB issued a research report on January 2, 2008 based upon findings and concerns from the Chalk's accident. The report provided information about air carrier financial and safety oversight programs and documented concerns regarding how the FAA "received cues from a number of sources that, when looked at in aggregate, served as indicators of potential safety deficiencies at Chalk's Ocean Airways, yet expressed no operational or maintenance concerns and did not modify Chalk's surveillance program."

Emergency Airworthiness Directive 2006-01-51 - One week after the accident, on December 30, 2005, the FAA issued an Emergency AD which directed operators of G-73 and G-73T airplanes to do the following:

Before further flight, perform a detailed visual inspection to detect repairs, cracking, or corrosion of the wings from WS 77L to WS 77R, front spar to rear (main) spar; remove any repair that is found to allow for inspection of the wing structure underneath the repairs; and remove the sealant from the interior of the wet bays to allow for inspection of the skins, stringers, and both spars.

Airplane Life Cycle

- Maintenance / Repair / Alteration

- Operational

Accident Threat Categories

- Structural Failure

Groupings

- Loss of Control

Accident Common Themes

- Organizational Lapses

Organization Lapses

Multiple red flags raised concerns regarding regulatory oversight and the organization's maintenance and operations practices including:

- Repetitive fuel leaks – A Chalk's captain stated that fuel leaks were of concern and "that it sometimes took 10 to 15 times to get a leak resolved" and were often improperly rectified by use of tank sealant instead of properly repairing the crack. On the accident aircraft, the repetitive fuel leaks near the area where the right wing separated from the fuselage were indicators of structural damage inside the right wing.

- Pilot maintenance concerns – Many Chalk's pilots expressed ongoing concerns to the director of operations regarding maintenance practices and the lack of a healthy safety culture. For example, maintenance personnel put undue pressure on the pilots to accept the aircraft "as is." As a result, three of the company's six captains left the airline less than one year prior to the accident. Post-accident interviews revealed that their reason for departure was due to maintenance concerns and in-flight events.

- Incomplete maintenance records – As part of the investigation, the NTSB noted missing maintenance documentation, discrepancies in records, and undocumented repairs.

- Safety oversight concerns – Investigators concluded that both managers from Chalk's safety organization and the FAA did not adequately address ongoing maintenance and repair issues to fully resolve airworthiness.

WSK PZL MIELEC M 18A, Brunswick, North Carolina, June 10, 2016

Source: NTSB

The experimental, restricted-category airplane experienced failure of the right wing due to a fatigue fracture of the right outboard wing forward spar lower fitting. Contributing to the accident was the routine operation of the airplane over its certificated maximum gross weight. Also contributing was the operator's improper or inadequate maintenance practices, which failed to apply a service life factor to the airplane to account for its overweight operation and failed to detect the extensive corrosion throughout the airplane.

Maintenance inspections failed to detect the pending failure of the wing, indicating inspections were performed inadequately or improperly. The company’s maintenance records also showed that the wing fittings on the accident airplane were replaced on three occasions in the 15 years before the accident, indicating that the company was not performing proper cleaning and corrosion prevention procedures.

NTSB accident report: ERA16LA209

Piper PA28R, Daytona Beach, Florida, April 4, 2018

Source: NTSB

This Piper Arrow airplane, N106ER, was mainly used for flight instruction and pilot certification at Embry Riddle. During flight, the airplane’s left wing separated from the fuselage near the wing root. The NTSB found the probable cause of this accident to be extensive fatigue cracking in the left-wing main spar lower cap and doublers which resulted in the in-flight separation of the left wing. The fatigue cracks initiated and grew to a critical size due to flight and ground loads associated with flight-training. Previously established inspection criteria were insufficient to detect the fatigue crack before it grew to a critical size.

NTSB accident report: ERA18FA120

Technical Related Lessons

Symptoms of discrepancies should not be masked with inappropriate solutions. Root causes must be identified before relying on a corrective action appropriate for a less severe cause which is critical when there is potential for a catastrophic outcome. (Threat Category - Structural Failure)

- In this accident, fuel leaks were the symptom of an unknown underlying cause. Maintenance personnel did not complete a root cause analysis. As a result, they only identified causal factors of fuel leaks but did not identify the root cause of cracked structure.

- Investigators determined the fuel leaks were due to the failure of a prior repair, resulting in a severely cracked and weakened structure. By focusing on sealant repairs, maintenance unintentionally masked the true cause of the leaks, which ultimately led to the airplane’s catastrophic wing failure.

The design and installation of repairs or modifications to critical structure should ensure that fatigue life and ultimate strength are fully considered. (Threat Category - Structural Failure)

- Numerous repairs on the accident aircraft and another airplane in the fleet did not fully restore the load-carrying capacity of the structures. The wing repairs on the accident aircraft lacked structural integrity which resulted in rapid crack progression. In addition, the installation of external doublers hid the crack progression and made it improbable that the cracks would be found prior to a catastrophic failure. The normal maintenance and recurrent inspection programs were insufficient for this substandard repair, as certain repairs can be so improperly implemented that catastrophic failure is probable.

- Improper repair techniques were used that included:

- Sanding to remove cracking

- Long-term use of stop-drill holes at skin cracks

- Double-drilled holes

- Rivets with undersized shop heads or ones that were too large and of different head types than specified

- Overdriven rivets

- Fasteners inserted through sealant instead of skin

Common Theme Related Lessons

Safety oversight should involve a cooperative arrangement between industry and regulator safety organizations to ensure quality practices are employed and deficiencies are identified and resolved. (Common Theme - Organizational Lapses)

- Oversight involves surveillance of multiple areas such as maintenance and safety practices, records documentation processes, regulatory compliance, and financial solvency.

- When the airline and regulators were repeatedly informed of various safety gaps, neither examined the safety oversight programs to ensure gaps resulted in corrective action.

- Repeated reports by pilots and passengers of fuel leaks (from cracked structure) did not lead airline operations, maintenance, or safety management nor the FAA to challenge the effectiveness and quality of the maintenance organization of the airline.

- Fuel leaks in the accident airplane were indicative of wing structural damage like those found on the sister aircraft. Despite wing structural damage and subsequent repairs made on the sister aircraft, fuel leaks in the accident airplane did not lead the operator or regulators to conclude that repair methods on the accident aircraft were insufficient.

- Investigators found the airline's maintenance and repair processes to be ineffective, poorly documented, and contained recurring discrepancies.