Boeing 747-244B Combi

Copyright Gerard Helmer - used with permission

South African Airways Flight 295, ZS-SAS

Mauritius, Indian Ocean

November 28, 1987

On November 28, 1987, South African Airways Flight 295 crashed into the Indian Ocean en route from Taipei's Chiang Kai Shek Airport to Mauritius's Plaisance Airport as the result of an uncontrolled fire in the airplane's main deck cargo compartment. All 159 people on board were lost. The crash occurred about ten hours into the flight, less than twenty minutes after the flight crew reported smoke to air traffic control in Mauritius. The airplane, a 747-200, was configured as a "combi," on which the main deck of the airplane is divided into two large sections, a passenger compartment and a cargo compartment. The method for controlling fires in main deck cargo compartments on combi airplanes relies heavily on manual firefighting using handheld fire extinguishers. Whether or not manual firefighting was attempted on Flight 295 is unclear but considering the size of the 747's main deck cargo compartment and the apparent rapid growth of the fire that occurred, the chance that such an attempt would have been successful is questionable. After the accident, the FAA and other airworthiness authorities concluded that reliance on manual firefighting as the primary means to control fires in large Class B cargo compartments was inadequate, and regulatory action was taken to require design and operational changes.

On November 28, 1987, South African Airways (SAA) Flight 295, a Boeing Model 747-200 airplane named "Helderberg" by SAA, crashed into the Indian Ocean enroute from Taipei's Chiang Kai Shek Airport to Mauritius's Plaisance Airport at a location about 110 miles off the island of Mauritius. All 159 people on board were lost. The crash occurred about ten hours into the flight, less than twenty minutes after the flight crew reported the presence of smoke on the airplane to air traffic control at Mauritius. The crash was attributed to an uncontrolled fire that occurred in the airplane's main deck cargo compartment. The crash site was in about 15,000 feet of water, which complicated recovery and investigation efforts. The investigation was conducted by the Republic of South Africa. Assistance was provided by the Federal Aviation Administration (FAA), the National Transportation Safety Board (NTSB), and Boeing. (View South Africa Airways Flight 295 flight path)

"Combi" Configuration

The SAA 747-200 was in a mixed passenger/freight configuration, known as a "combi" configuration. The main deck for 747 combi models is divided into a forward passenger compartment and a large aft cargo compartment. (View location of Flight 295's Main Deck Cargo Area) Other airplane models that have combi configurations, such as the 727 and 737, have the main deck cargo compartment located forward of the passenger compartment rather than aft. In either case, the passenger and cargo compartments are separated by a rigid barrier, and this barrier has a door to allow crew members access to the cargo compartment during flight. On the 747-200 combi, the barrier between the passenger and cargo compartments cannot be easily repositioned or removed, resulting in a fixed passenger/cargo ratio. View Typical 747 combi floor plan. For other models, such as the 727 and 737, the partition can be readily moved to different locations or removed entirely within minutes to convert the airplane into all passenger, all freight, or various passenger/freight combi configurations to accommodate daily or seasonal operational needs. View Typical 737 combi floor plan.

Main deck cargo compartments on combi airplanes are generally certified by the FAA as "Class B" cargo compartments as defined by 14 CFR part 25 §25.857(b) design requirements. View Relevant Part 25 regulations. To meet FAA design requirements, a Class B cargo compartment must have a fire detection system to alert the flight crew of the presence of a cargo fire. It is not required to have a built-in fire suppression system. If a fire occurs in the compartment, the primary means to control it is via a crewmember entering the compartment and using hand-held fire extinguishers. Supporting airplane features, like seals, liners, and ventilation systems, are designed to ensure that if a main deck cargo fire occurs, it will be contained within the compartment until manual firefighting can be successfully accomplished, and to ensure that hazardous amounts of smoke, flames, and extinguishing agent do not enter areas of the airplane occupied by people, such as the cockpit and passenger cabin.

Flight 295

SAA Flight 295 departed Taipei's Chiang Kai Shek airport shortly after 2:23 pm with 140 passengers and 19 crew members on board. Calculated flight time to Mauritius' Plaisance Airport was 10 hours and 14 minutes. The airplane's main deck Class B cargo compartment was loaded with six large pallets of cargo, which consisted primarily of electrical items (including computers), hardware, paper articles, textiles, and sports equipment, packaged with materials that included cardboard and plastic. The height of the cargo loaded on each pallet was reported to be about seven feet.

More than nine hours into the flight and only about 45 minutes before expected arrival in Mauritius, the flight crew reported smoke to Mauritius Approach Control (MRU) and proceeded to declare an emergency. The airplane's fire detection system had detected smoke in the Class B cargo compartment, and an audible alarm was provided in the cockpit. This alarm could be heard on the airplane's cockpit voice recorder (CVR) tape, which was reviewed after the accident. The alarm likely occurred shortly before Flight 295 contacted MRU to report the smoke. Unfortunately, the CVR and the wiring to it were located in the vicinity of the Class B cargo compartment, and damage from the fire rendered the CVR inoperable within eighty seconds after the audible alarm can be heard on the tape. As such, determining precisely how much time elapsed between the alarm and when contact with MRU was made was not possible because the contact with MRU was made after the CVR failed. The time was probably a matter of minutes, during which the flight crew was likely involved in emergency procedures associated with detection of a cargo fire (Emergency checklist for main deck fire smoke) and control of smoke. (Emergency checklist for main deck smoke evacuation)

Flight 295's initial report of smoke to MRU was made at about 11:49pm. Communications between Flight 295 and MRU continued for about fifteen minutes before contact was lost. These fifteen minutes of communications between Flight 295 and MRU that were recorded by MRU, along with the limited recording from the damaged CVR, provide information about crew activities in the last minutes of the flight. The flight data recorder (FDR) was not recovered from the crash site, but like the CVR was located in the vicinity of the Class B cargo compartment and would have been susceptible to the same kind of fire damage as the CVR.

Review of the CVR tape and the communications recorded by MRU indicate that the emergency on board developed quickly. Within four seconds of the audible smoke detection warning in the cockpit, an intercom chime can be heard on the CVR tape, possibly indicating that the flight attendants in the passenger cabin had become aware of the fire nearly simultaneously. Another intercom chime occurred about one minute later, possibly a further attempt by the flight attendants to contact the flight crew. Many of the communications with Flight 295 recorded by MRU were related to plans for an emergency landing at Plaisance Airport, but the recording also picked up some of the communications within the cockpit between crewmembers. About two minutes after the first communication with MRU regarding smoke, the pilot reported, "we've lost a lot of electrics, we haven't got anything on the aircraft now," an indication that the fire was likely affecting airplane systems. (Transcript of CVR and MRU recordings)

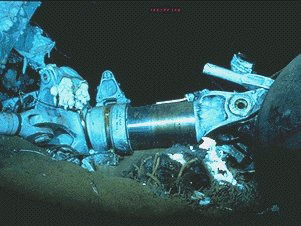

Flight 295's last communication with MRU occurred at about 12:04am. The airplane crashed into the Indian Ocean off the coast of Mauritius in 15,000 feet of water at about 12:07am (4:07am local time). The Republic of South Africa Accident Inquiry Board (SAAIB) conducted the crash investigation, with support from the FAA, NTSB, and Boeing. The remote location and depth of the water at the crash site, along with poor weather conditions, complicated recovery and investigation efforts. Some limited floating wreckage was recovered, consisting mostly of light cargo, cabin paneling and furnishings, and escape slides/rafts. Most of the wreckage was submerged in two large debris fields. Few items were actually recovered from the sea floor. Examination of most of the wreckage was limited to use of underwater photographic and video equipment.

Underwater photos of Flight 295 wreckage

Investigation

The SAAIB concluded that an intense fire had developed in the Class B cargo compartment at the forward right hand pallet position, just aft of the barrier between the passenger and cargo compartments and the cargo net, and that the fire had spread to the middle left and aft right cargo pallet positions, causing extensive heat damage to wiring and liners inside the cargo compartment and the adjacent fuselage structure. (View South African Airways Class B Cargo Fire Animation below.) The SAAIB also concluded that substances involved in the fire included plastic and cardboard packing materials, and that smoke, carbon monoxide, and carbon dioxide from the fire had entered the passenger cabin. The SAAIB published its findings in their "Report of the Board of Inquiry into the Helderberg Air Disaster," dated May 14, 1990. (SAAIB report)

The ignition source for the fire could not be determined, nor could the precise event that precipitated the crash of the airplane following detection of the fire. The flight crew's last communication with MRU sounded relatively calm and related to plans for the emergency landing. The SAAIB concluded that the airplane was not under control when it crashed into the sea at high speed about three minutes later. Evidence showed that the airplane's wing struck the water in a perpendicular position and that the engines were not turning. Specific events identified by the SAAIB that could have precipitated the crash included 1) crew incapacitation, 2) crew distraction, 3) heat-related weakening of the structure causing in-flight break-up, 4) heat-related damage to flight control cables, and 5) heat-related deformation of the fuselage.

Regardless of the cause of the fire and the specific event that precipitated the crash, the SAAIB, NTSB, and FAA all concluded that the existing Class B cargo compartment fire protection features on the SAA airplane were inadequate, particularly the reliance on manual firefighting as the primary means to control a fire in the cargo compartment. This determination was documented in the SAAIB report, an NTSB Safety Recommendation, dated May 16, 1988, and a report developed by a team led by the FAA (FAA report). Each organization recognized the need for additional research and recommended interim actions that included use of fire resistant containers for all cargo.

Follow-up Activities

For several years following the accident, the FAA conducted research and evaluated potential design and operational changes to improve the safety of Class B cargo compartments. Considerable testing was conducted by the FAA Technical Center, including evaluations related to manual firefighting with hand-held fire extinguishers and the use of fire resistant covers and containers for cargo carriage. (FAA Technical Center reports: Cargo Compartment Fire Protection in Large commercial Transport Aircraft, Effectiveness of Flight Attendants Attempting to Extinguish Fires in an Accessible Cargo Compartment, Effectiveness of Hand-Held Fire Extinguishers on Cargo Container Fires, Evaluation of Large Class B Cargo Compartment's Fire Protection) During this time, the FAA issued a series of Airworthiness Directives (ADs) applicable to large transport category airplanes, such as the 737 and 747, which were considered to be at the highest risk if a cargo fire occurred. The first AD, AD89-18-12 (Notice of Proposed Rulemaking 88-NM-80-AD) was issued shortly after the accident and required airplane design and operational changes directly related to some of the findings and recommendations related to the SAA accident. The AD required operators of combi airplanes with Class B cargo compartments to accomplish some short-term operational and equipment changes, and within three years to either:

- Convert the existing Class B cargo compartment to Class C, which would include developing and installing a built-in fire suppression system and improved cargo compartment liners, or

- Carry all cargo in the Class B cargo compartment in containers that meet Class C requirements. Such containers would have to be developed and would be required to incorporate fire protection features, including built-in fire detection and suppression capability.

AD 89-18-12R1 was issued shortly after the release of AD 89-18-12 in response to industry requests for a third option to be added to the AD. This third option once again relied heavily on manual firefighting, but with significant improvements such as more comprehensive firefighter training, additional firefighting equipment, improved cargo compartment liners, and installation of a fifteen-minute-duration fire suppression system to "knock down" the fire prior to entry of the trained firefighter in the cargo compartment for manual firefighting.

Following issuance of AD 89-18-12R1, industry reported significant design, cost, and operational difficulties in complying with any of the three options within the timeframe prescribed by the AD. Designing and implementing Class C features on an existing airplane per the first option of the AD was considered prohibitively expensive and would require significant changes to existing airplane systems. Designing specialized containers that have Class C features and integrating these containers into airline operations per the second option of the AD was considered costly and logistically unmanageable. Implementing highly trained firefighters on every flight per the third option of the AD was also considered logistically unmanageable. In addition, the FAA had increasing concerns that even trained firefighters could not effectively control in-flight fires, in part due to some tests that indicated that even trained firefighters could not effectively combat fires in large cargo compartments due to factors such as size of the pallets and containers of cargo, limited access provisions, anticipated fire and smoke conditions in the compartment during firefighting, and kind of firefighting equipment available.

The FAA continued to review Class B cargo compartment fire protection deficiencies, challenges, and potential solutions. The FAA recognized the need to provide operators with short-term relief from some of the requirements of AD 89-18-12R1 due to the impending deadlines for compliance with the AD, the actual time needed to develop and implement the options provided in the AD, and concerns about the effectiveness of some of these options. In response to these concerns, the FAA superseded AD 89-18-12R1 with AD 91-10-02, (NPRM 91-NM-34-AD) to provide relief from some of the immediate requirements of AD 89-18-12R1, and more significantly, solicit additional public comments regarding Class B cargo compartment fire protection approaches.

The FAA reviewed the public comments submitted in conjunction with issuance of AD 91-10-02, along with data from testing conducted by the FAA Technical Center. As the result, the FAA developed and issued a final directive, AD 93-07-15, (P-2 - NPRM 92-NM-67-AD) which superseded the three earlier ADs. AD 93-07-15 retained the first two options of the previous ADs, but eliminated entirely the third option related to use of highly trained firefighters as the primary means to control cargo fires. This AD also offered two new options. In summary, the four options provided by the AD 93-07-15 were:

- Convert the Class B cargo compartment to Class C,

- Use containers that meet the requirements of Class C for all cargo carried in the Class B cargo compartment,

- Use fire-resistant covers or containers for all cargo, along with other design, equipment, and operational modifications, or

- Incorporate a long-duration fire suppression system, along with other design, equipment, and operational modifications.

Because of the costs of implementing AD 93-07-15 and earlier versions of the AD, some operators chose to eliminate main deck Class B cargo compartments entirely from their airplanes, converting them to all-passenger or all-freight configurations. Most 747 combi operators that chose to retain their Class B cargo compartments selected the fourth option. Operators of smaller combis, such as the 727 and 737 combis, generally chose the third option.

Copyright Tim Rees - used with permission

The Republic of South Africa investigated the loss of South African Airways (SAA) Flight 295, with assistance from the National Transportation Safety Board (NTSB) and the Federal Aviation Administration (FAA). Findings by the Republic of South Africa Accident Inquiry Board (SAAIB) were published in their "Report of the Board of Inquiry Into the Helderberg Air Disaster." NTSB and FAA findings and conclusions were also published in NTSB Safety Recommendations A-88-61 through -63, issued on May 16, 1988, and the FAA's report "Evaluation of Transport Airplane Main Deck Cargo Compartment Fire Protection Certification Procedures," dated June 1, 1988, respectively. All three organizations concluded that existing Class B cargo compartment fire protection features on large transport airplanes were not adequate.

SAAIB Findings

Some significant SAAIB findings are identified below. A full listing can be found in the SAAIB report.

- The fire started at the right forward cargo pallet position. It involved packing materials, and it generated a considerable amount of smoke which entered the passenger cabin and possibly the cockpit, and likely resulted in loss of consciousness or death for at least some occupants. The fire caused extensive heat damage to the fuselage structure, insulation blankets, and electrical wiring in the main deck cargo compartment area.

- FAA Class B cargo compartment standards and substantiation methods were not adequate. Smoke detection methods did not provide warning early enough for manual firefighting to be effective. Tests to demonstrate that hazardous amounts of smoke would not enter occupied areas of the airplane did not account for the effect of heat generated by the fire. Firefighting procedures and equipment were not adequate.

NTSB Findings

Some of the NTSB conclusions documented in their Safety Recommendation, dated May 16, 1988, are listed below. Further details are found in the NTSB recommendation itself. (NTSB recommendations):

- Class B cargo compartment regulations for fire detection and suppression were inadequate. Some fire detection test methods might not address realistic conditions in the cargo compartment that could impede detection of the fire, such as use of plastic covers on cargo pallets. Once a fire propagates in a Class B compartment, the ability of a crewmember to effectively combat it would be limited, even under ideal circumstances. Smoke conditions could make locating the fire difficult and reaching the fire with a hand-held extinguisher might not be possible, particularly if the fire was deep seated within a cargo container or stacked pallet. A hand-held fire extinguisher contains a limited amount of extinguishing agent, which might not be enough to extinguish the fire or provide suppression for the balance of the flight, which could be several hours.

- More research was needed to establish means for ensuring that airplanes with Class B cargo compartments are adequately protected in the event of a cargo fire.

FAA Findings

The FAA report, entitled "Evaluation of Transport Airplane Main Deck Cargo Compartment Fire Protection Certification Procedures," dated June 1, 1988, identified the following. Further details are found in the FAA report itself. (FAA report)

- The existing rules, policies, and procedures that were applied to certification of Class B cargo compartment fire and smoke protection features were not adequate. The fire detection system did not provide an early enough warning in the event of a fire. Smoke and access limitations within the cargo compartment could impede manual firefighting efforts. The number of hand-held fire extinguishers and the total amount of extinguishing agent were not sufficient.

- Reliance on crew members to fight cargo fires must be discontinued.

The Republic of South Africa conducted the investigation into the loss of South African Airways (SAA) Flight 295. Assistance was provided by the National Transportation Safety Board (NTSB) and the Federal Aviation Administration (FAA). Recommendations by the Republic of South Africa Accident Inquiry Board (SAAIB) were published in their "Report of the Board of Inquiry Into the Helderberg Air Disaster." The NTSB issued Safety Recommendations A-88-61 through -63 on May 16, 1988, and the FAA provided recommendations in a FAA report developed by a team of regulatory and industry representatives, entitled "Evaluation of Transport Airplane Main Deck Cargo Compartment Fire Protection Certification Procedures," dated June 1, 1988. The FAA issued Airworthiness Directive (AD) 89-18-12R1, which required design and operational changes directly related to these recommendations. However, this AD was later superseded twice based on subsequent evaluation of Class B cargo compartment fire protection system design, implementation, and cost considerations, and based on further FAA research revealing shortcomings related to some of the approaches allowable per AD 89-18-12R1.

SAAIB Recommendations

Significant recommendations by the SAAIB, included:

- Ban combi configuration operations until improvements are incorporated to address Class B cargo compartment fire protection shortcomings.

- Require incorporation of FAA AD 89-18-12R1 to minimize hazards associated with main deck cargo fires for current combi operations.

- Protect the cockpit voice and flight data recorders to ensure that they remain operational in the event of a cargo fire.

NTSB Recommendations

Three NTSB recommendations issued were as follows:

- Until fire detection and suppression methods for Class B cargo compartment fires are evaluated and revised, as necessary, require all cargo carried in Class B cargo compartments of United States registered transport category airplanes to be carried in fire resistant containers,

- Conduct research to establish the fire detection and suppression methods needed to protect transport category airplanes from catastrophic fires in Class B compartments,

- Establish fire resistant requirements for the ceiling and sidewall liners in Class B cargo compartments that equal or exceed the requirements for Class C and D compartments as set forth in 14 CFR Part 25, Appendix F, Part III.

FAA Recommendations

Significant recommendations by the FAA included:

- Main deck cargo compartments must provide a level of safety equal to that of Class C cargo compartments, or all cargo carried in Class B cargo compartments must be carried in containers that incorporate Class C cargo compartment features like fire detection and extinguishing systems.

- Limit the size of Class B cargo compartments allowable under the current Class B standard.

- Incorporate improvements in the fire detection system and the barrier between the passenger and cargo compartments to ensure smoke and fumes from the cargo compartment do not enter occupied areas of the airplane.

Note that the actual changes later implemented by the FAA differed from some of the recommendations. This was the result of information later obtained through research and testing following the accident, and further review of design, implementation, and operational issues related to Class B cargo compartment fire protection.

14 CFR part 25 § 25.857 Cargo compartment classification. (Issued 11/3/64)

(b) Class B. A Class B cargo or baggage compartment is one in which -

(1) There is sufficient access in flight to enable a crewmember to effectively reach any part of the compartment with the contents of a hand fire extinguisher;

(2) When the access provisions are being used, no hazardous quantity of smoke, flames, or extinguishing agent, will enter any compartment occupied by crew or passengers;

(3) There is a separate approved smoke detector or fire detector system to give warning at the pilot or flight engineer station; and

(4) There is a fire-resistant lining.

14 CFR part 25 § 25.851 Fire extinguishers. (Issued 11/3/64)

(a) Hand fire extinguishers.

(1) Each hand fire extinguisher must be approved.

(2) The types and quantities of each extinguishing agent used must be appropriate to the kinds of fires likely to occur where used.

(3) Each extinguisher for use in a personnel compartment must be designed to minimize the hazard of toxic gas concentrations.

(4) A readily accessible hand fire extinguisher must be available for use in each Class A or Class B compartment.

14 CFR part 25 § 25.855 Cargo and baggage compartments. (Issued 11/3/64)

(a) Each cargo and baggage compartment (including tie-down equipment) must be constructed of materials that are at least flame resistant.

(b) No compartment may contain any controls, wiring, lines, equipment, or accessories whose damage or failure would affect safe operation, unless those items are protected so that-

(1) They cannot be damaged by the movement of cargo in the compartment; and

(2) Their breakage or failure will not create a fire hazard.

(c) There must be a means to prevent cargo or baggage from interfering with the functioning of the fire-protective features of the compartment.

(d) Sources of heat within the compartment must be shielded and insulated to prevent igniting the cargo.

(e) Cargo compartments must meet one of the class requirements of Sec. 25.857. In addition, flight tests must be conducted to show compliance with the provisions of Sec. 25.857 concerning -

(1) Compartment accessibility;

(2) Entry of hazardous quantities of smoke or extinguishing agent into the compartments occupied by the crew or passengers; and

(3) The dissipation of the extinguishing agent in Class C compartments.

During these tests, it must be shown that no inadvertent operation of smoke or fire detectors in any compartment would occur as the result of fire contained in any one compartment, either during or after extinguishment, unless the extinguishing system floods each such compartment simultaneously.

Prior to the SAA accident, manual firefighting was considered an adequate means for controlling fires in Class B cargo compartments ranging in size from small commuter airplanes to large airplanes like the 737 and 747. Among the FAA's available large cargo compartment classifications, only Class B cargo compartments rely on manual firefighting as the primary means for controlling cargo fires. A Class C compartment, such as a lower lobe baggage compartment, must have a built-in fire suppression system to flood the compartment with extinguishing agent if a fire is detected. A Class D compartment, permissible at the time of the SAA accident, relied on passively starving the fire of oxygen by limiting the compartment's volume and ventilation. The Class D cargo compartment classification is no longer available under FAA regulations as the result of the ValuJet DC-9 accident. Class E compartments, found on freight-only airplanes, rely on depressurizing the airplane and maintaining a cabin altitude between 20k and 25k feet to essentially starve the fire of oxygen.

The FAA regulations for Class B cargo compartments, with their reliance on manual firefighting as the primary means to control cargo fires, are essentially unchanged since the 1940s. The FAA continued to certify airplanes with Class B cargo compartments without re-evaluating the effectiveness of the Class B approach as airplane design and usage evolved over time, resulting in larger airplanes and longer emergency diversion distances. In the case of the 747-200 combi, the Class B cargo compartment was too large, and the emergency diversion distances were too large for manual firefighting to be effective as the primary means to control a cargo fire.

Class B cargo compartment fire protection features, relying heavily on manual firefighting, are inadequate to control cargo fires in large Class B cargo compartments.

Manual firefighting can effectively control a cargo fire that occurs in the 747 main deck Class B cargo compartment.

Saudi Arabian Airlines, Flight 163, Lockheed L-1011, HZ-AHK, Riyadh, Saudi Arabia, August 19, 1980

Seven minutes after take-off an aural warning indicated smoke in the aft cargo compartment. In response to information received from the flight attendants, the flight engineer went into the passenger cabin and reported back that there was fire and smoke emanating from the extreme aft area of the cabin. The aircraft returned to Riyadh and taxied off the runway to a taxiway. It was several minutes after stopping the airplane on the taxiway before the engines were shut down. Following the landing, and prior to initiation of an evacuation, all of the occupants were incapacitated by the smoke and fire inside the airplane. An evacuation was never initiated. All 301 passengers and crew perished in the fire. The fundamental fire protection philosophy proved to be flawed and allowed the fire to burn until it became catastrophic.

See accident module

n Aviation Rulemaking Advisory Committee (ARAC) Cargo Standards Harmonization Working Group was formed to develop new or revised requirements for Class B cargo compartments. The working group was tasked to develop a draft NPRM, and collateral material, such as advisory circulars, etc. The working group's final submittal to the FAA provided recommendations for both regulatory revisions, and new advisory material. A final rule, Harmonization of Airworthiness Standards: Fire Extinguishers and Class B and F Cargo Compartments (FAA-2014-0001-0013), was promulgated in 2016. The rule amended certain airworthiness regulations for transport category airplanes by upgrading fire safety standards for Class B cargo compartments; establishing fire safety standards for a new type of cargo compartment, Class F; and updating related standards for fire extinguishers.

AD 89-18-12 required operational and equipment changes and design modifications to maximize cargo fire detection and control. This AD applied to Boeing Models 707, 727, 737, 747, and 757 series airplanes; and McDonnell Douglas Models DC-8, DC-9 (includes MD-80 series), and DC-10 series airplanes, equipped with a main deck Class B cargo compartment, as defined by FAR 25.B57{b) or its predecessors, with a volume exceeding 200 cu. ft., certificated in any category.. This AD was proposed via NPRM 88-NM-80-AD and superseded by AD 89-18-12R1.

AD 89-18-12R1 revised AD 89-18-12 to add a third option to the AD, relying heavily on manual firefighting, but with significant improvements such as more comprehensive firefighter training, additional firefighting equipment, improved cargo compartment liners, and installation of a fifteen-minute-duration fire suppression system to "knock down" the fire prior to entry of the trained firefighter in the cargo compartment for manual firefighting, This AD was superseded by AD 91-10-02.

AD 91-10-02 provided relief from some of the immediate requirements of AD 89-18-12R1. This AD was proposed via NPRM 91-NM-34-AD, which solicited additional public comments regarding Class B cargo compartment fire protection approaches. AD 91-10-02 was superseded by AD 93-07-15.

Airworthiness Directive (AD) 93-07-15 requires design, equipment, and operational changes related to Class B cargo compartments in large transport category airplanes manufactured by Boeing and McDonnell Douglas. This AD provides four options:

- Convert the Class B cargo compartment to Class C, as defined in 14 CFR part 25.857(c), which includes upgrading the liner and installing a fire suppression system.

- Use containers that meet the requirements of Class C for all cargo carried in the Class B cargo compartment.

- Use fire resistant covers or containers for all cargo, along with incorporating other design, equipment, and operational modifications.

- Incorporate a long duration fire suppression system, along with other design, equipment, and operational modifications.

Airplane Life Cycle:

- Design / Manufacturing

Accident Threat Categories:

- Uncontrolled Fire / Smoke

Groupings:

- N/A

Accident Common Themes:

- Flawed Assumptions

Continuing to approve airplane designs that are based on established design approaches without consideration of evolutionary changes in overall airplane design and usage can have catastrophic consequences. The primary means to control a fire in a Class B cargo compartment is manual firefighting. The FAA regulations related to Class B cargo compartments were established in the 1940s. The same methodologies applied to approving past smaller Class B cargo compartment designs continued to be applied to newer designs such as the 747, resulting in approval of a design that did not provide adequate cargo fire protection. Class B cargo compartments on modern airplanes such as the 747 can be significantly larger than their predecessors, and these newer airplanes can support longer, over water routes, which can result in lengthy diversion times if a fire occurs. Manual firefighting is not an effective means for controlling fires in large cargo compartments or for lengthy diversions.

ValuJet Flight 592, McDonnell Douglas DC-9, N904VJ, Miami, Florida, May 11, 1996

Following takeoff from Miami, oxygen generators that had been loaded as cargo ignited in the forward cargo compartment. The fire penetrated the passenger cabin and incapacitated the crew. The airplane crashed, killing all onboard.

See accident module

Saudi Arabian Airlines Flight 163, Lockheed L-1011, HZ-AHK, Riyadh, Saudi Arabia, August 19, 1980

Following takeoff from Riyadh, Saudi Arabia an inflight fire in the aft cargo compartment necessitated a return to Riyadh. The fire burned through the cargo compartment liner into the passenger cabin. All passengers and crew were killed.

See accident module

Technical Related Lessons:

Design features and associated procedures must be adequate to ensure that if a fire occurs in a cargo compartment, it can be controlled for the duration of a diversion and until the airplane can be safely landed. (Threat Category: Uncontrolled Fire)

- SAA Flight 295 involved a fire in a large Class B cargo compartment. The primary method for controlling fires in Class B cargo compartments at the time of this accident was manual firefighting. Although FAA requirements for Class B cargo compartments do not explicitly limit cargo compartment size, manual firefighting was determined to not be an effective means for controlling fires that occur in large main deck cargo compartments. It was determined that the crash of SAA Flight 295 was the result of inadequate cargo fire protection and a resulting uncontrolled fire. Subsequent to the accident, airworthiness directives were issued that specified new fire protection criteria in Class B compartments.

Common Theme Related Lessons:

Fire control strategies, for large Class B compartments, that depend on manual firefighting have been shown to be inadequate. (Common Theme: Flawed Assumptions)

- Large Class B compartments may present particular difficulties related to controlling, or extinguishing fires. Compartment size may make location of the fire, or access to the fire, once discovered, difficult. In this accident, the SAA 747 Combi provided a large cargo compartment aft of the passenger cabin, which was capable of carrying a large volume of cargo with a wide variation in size, location, and content. Manual firefighting in this type of compartment presented an unrealistic task in identifying, accessing, and dispersing extinguishing agent. In some cases, pallet sizes were very large, and covered with material that made access to the fire source difficult. Long flight durations of a 747 can also result in long emergency diversion times to reach a suitable airport, further complicating the problem associated with containing and/or suppressing a cargo compartment fire.